الوصف

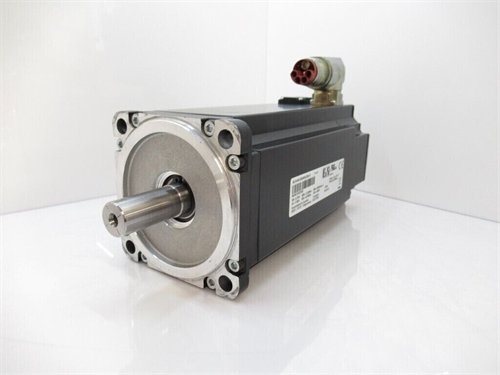

The B&R 8LSA44.DB030S300-3 is a synchronous servo motor from B&R’s 8LS series, specifically designed for applications requiring a holding brake and a high-resolution absolute encoder.

B&R 8LSA44.DB030S300-3: Synchronous Servo Motor with Holding Brake and Absolute Encoder

This part number precisely defines a specific configuration within B&R’s 8LS synchronous motor series. These motors are highly regarded for their compact design, high power density, and excellent dynamic performance, making them suitable for demanding industrial automation tasks.

Key Specifications and Features:

- Type: Synchronous Servo Motor

- Manufacturer: B&R Automation (now part of ABB)

- Series: 8LS

- Frame Size: Size 4 (indicated by “A44”). This is a mid-range motor within the 8LS family, offering a good balance of power and compactness. It has a typical centering diameter of 95 mm for mounting.

- Rated Speed: 3000 RPM (revolutions per minute).

- Nominal Torque: Approximately 4.6 Nm (Newton-meters).

- Stall Torque: Approximately 6.0 Nm.

- Nominal Current: Around 2.8 A.

- Stall Current: Around 3.7 A.

- Nominal Power: Around 1445 W.

- Maximum Torque: Can reach up to 23.5 Nm.

- Maximum Current: Up to 18.7 A.

- Maximum Speed: Can reach up to 9000 RPM.

- Voltage: Operates at 400 V.

- Shaft: Smooth shaft. While some “DB” models can have a keyway depending on the exact variant, the most common configuration for 8LS with brake is a smooth shaft.

- Connectors: Features angled swivel connectors, providing flexibility for cable routing.

- Brake: The “DB” in the part number explicitly indicates that this motor includes an integrated holding brake.

- Holding Torque of Brake (MBr): For a size 4 motor (like an 8LSA44), the holding torque of the brake is typically 10.0 Nm. This brake is crucial for holding the load securely in position when power is removed, during a stop, or to prevent unwanted movement.

- Protection Class: IP64, indicating it is protected against dust ingress and splashing water from any direction.

- Cooling: Self-cooling (construction type A), relying on natural convection for heat dissipation.

- Pole Pairs: Typically 5 pole pairs.

- Feedback System: The “S300” refers to the encoder system. For B&R 8LS motors, “S300” typically denotes a multi-turn absolute encoder, specifically an EnDat 2.2 multi-turn encoder. This provides highly precise absolute position feedback over multiple revolutions, eliminating the need for homing procedures and often using a gear-based counter (battery-less).

- Embedded Parameter Chip: B&R 8LS motors come with an embedded parameter chip within the encoder that stores all relevant mechanical and electrical information. This allows the paired B&R ACOPOS servo drive to automatically identify the motor and configure itself for optimal control, simplifying commissioning.

- Version: The “-3” typically indicates a specific version or revision of the motor.

Decoding the Part Number:

- 8LS: Denotes the 8LS Synchronous Motor series.

- A44: Specifies the motor type and dimensions (self-cooled, flange-mounted, Size 4).

- DB: Indicates the connection type and presence of a brake (angled swivel connectors, with brake).

- 030: Relates to the nominal speed (3000 rpm).

- S300: Specifies the integrated feedback system (multi-turn absolute encoder, EnDat 2.2).

- -3: Indicates the version or revision.

Typical Applications:

Given its combination of precision, dynamic response, and particularly the integrated multi-turn absolute encoder and holding brake, the B&R 8LSA44.DB030S300-3 is ideal for applications where:

- Vertical Axes: Holding loads precisely against gravity without drift, such as in lifting mechanisms, gantry systems, or Z-axes on machine tools.

- Precision Positioning: Applications requiring extremely accurate and repeatable positioning, even after power cycles, as the absolute encoder retains its position information.

- Robotics: In robotic arms or applications where safe stopping and holding of manipulators are crucial.

- Machine Tools: For axes that require both dynamic motion and secure holding, and precise absolute position tracking.

- Automated Storage and Retrieval Systems (AS/RS): For precise and safe movement and positioning of goods.

- Packaging Machinery: For accurate indexing, stopping, and holding of product or machine components.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922