الوصف

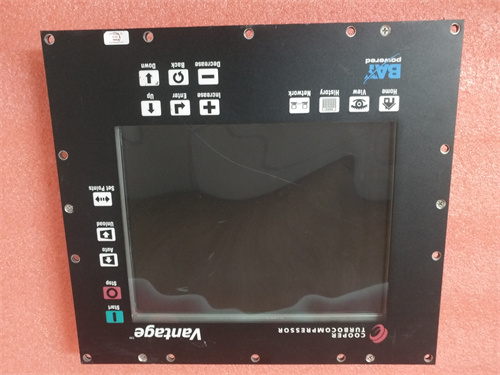

The COOPER P3798102-00010 CN-UIM2 is specifically identified as a User Interface Module (UIM) for Cooper Turbocompressors, particularly within their Vantage Control Panel series. It is a critical HMI (Human-Machine Interface) component that allows operators to interact with, monitor, and control industrial turbocompressors.

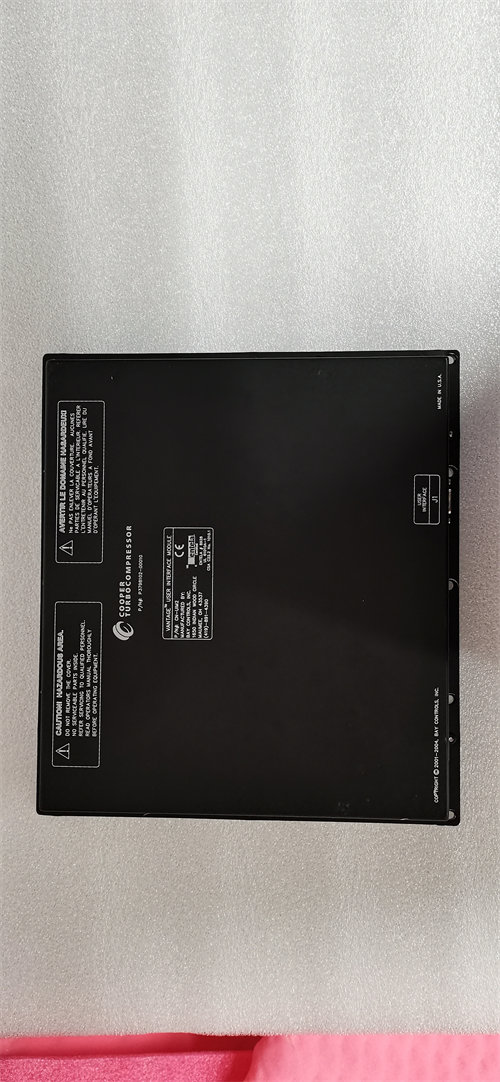

The full part number, P3798102-00010, is typically for the complete assembly which includes the CN-UIM2 as the User Interface Module.

This module is the operator’s window into the compressor’s operations, displaying real-time data, alarms, and settings, and enabling adjustments to ensure efficient and safe performance.

Part One: Optimized SEO Titles

- COOPER P3798102-00010 CN-UIM2: Turbocompressor User Interface Module

- CN-UIM2 Cooper: Vantage Control Panel HMI for Compressors

- COOPER P3798102-00010: Industrial Compressor Display Module

- Buy P3798102-00010 CN-UIM2: Genuine Cooper Turbocompressor Part

- CN-UIM2 for Sale: Enhancing Compressor Monitoring & Control

- COOPER P3798102-00010: Integrated User Interface & Keypad

- Turbocompressor HMI CN-UIM2: For Optimal Performance

- P3798102-00010: Cooper Vantage Series Operator Panel

- COOPER CN-UIM2: Reliable Compressor System Interface

- P3798102-00010 CN-UIM2: Diagnostics & Data for Turbocompressors

Part Two: Brief Product Description

The COOPER P3798102-00010 CN-UIM2 is a User Interface Module (UIM) designed for Cooper Turbocompressor Vantage Control Panels. It features a full-page, back-lit liquid crystal LCD display and an integrated 15-key tactile keypad, providing detailed information on the operational condition, settings, and diagnostics of the compressor. This robust HMI module enables seamless interaction, monitoring, and control of turbocompressors in industrial environments.

- Product Type: User Interface Module (UIM) / HMI Panel

- Manufacturer: Cooper (Cooper Turbocompressor / Bay Controls)

- Model/Part Number: P3798102-00010 (includes CN-UIM2)

- Compatibility: Cooper Turbocompressor Vantage Control Panel series

- Function: Real-time monitoring, control, configuration, and diagnostics for turbocompressors.

Part Three: Detailed Product Description

In industrial settings like manufacturing plants, refineries, or power stations, turbocompressors are vital for processes requiring large volumes of compressed air or gas. The efficiency, reliability, and safety of these compressors heavily depend on precise control and clear operational visibility. This is where the COOPER P3798102-00010 CN-UIM2 User Interface Module plays a crucial role. It serves as the primary window for operators into the complex machinery, translating intricate operational data into an easily understandable format and allowing for direct interaction and control.

I recall an instance at a large food processing plant where a critical air compressor started showing intermittent performance issues. The control room staff, miles away, could see high-level alarms, but couldn’t pinpoint the exact cause. It was only when a technician went to the compressor and accessed the COOPER CN-UIM2 on the Vantage panel that the detailed diagnostics, including specific sensor readings and error codes, revealed a subtle pressure imbalance. The ability to access granular operational data directly at the machine via the UIM was key to quickly identifying and resolving the issue, preventing a potential shutdown of the entire production line. This highlights the indispensable nature of a robust and informative HMI like the CN-UIM2 for efficient troubleshooting and operational continuity.

Comprehensive Control and Monitoring: The COOPER P3798102-00010 CN-UIM2 is designed to provide a comprehensive human-machine interface for Cooper Turbocompressors. Its key features include:

- Full-Page, Back-lit LCD Display: Offers a clear and detailed view of compressor parameters, alarms, and status messages, even in varying lighting conditions. This allows operators to quickly grasp the machine’s operational state.

- Integrated 15-Key Tactile Keypad: Provides a robust and intuitive means for operators to navigate menus, input commands, and adjust settings. The tactile feedback ensures confident operation in industrial environments.

- Real-time Data Display: Shows essential operational data such as:

- Discharge pressure and temperature

- Suction pressure and temperature

- Motor current and voltage

- Bearing temperatures

- Vibration levels

- Oil pressure and temperature

- Run hours and maintenance alerts

- Alarm and Event Management: Displays active alarms, historical alarm logs, and event records, crucial for diagnostics and understanding the sequence of events leading to a fault.

- Configuration and Settings: Allows authorized personnel to adjust various operating parameters and control settings for the compressor, optimizing its performance for specific application needs.

- Diagnostics and Troubleshooting: Provides access to detailed diagnostic information, aiding technicians in quickly identifying and resolving issues, thereby reducing downtime.

Robust Design for Industrial Environments: Given that it operates directly on turbocompressors, often in harsh industrial settings, the CN-UIM2 is built for durability and reliability:

- Industrial-Grade Construction: Designed to withstand vibrations, temperature fluctuations, and potential exposure to dust or moisture.

- Integral Part of Vantage Control Panel: It is specifically designed to fit and integrate seamlessly with the Cooper Turbocompressor Vantage control panel, ensuring physical and electrical compatibility. This panel also typically includes the Main Logic Module (MLM) which houses the processor and I/O.

- Reliable Performance: Ensures continuous and accurate information display and user interaction, which is vital for the safe and efficient operation of critical compressor units.

Technical Specifications (General, as precise details can vary by compressor model and specific UIM revision; always consult official Cooper Turbocompressor documentation):

Key Applications:

The COOPER P3798102-00010 CN-UIM2 is specifically used in conjunction with Cooper Turbocompressors in a wide range of industrial sectors:

- Manufacturing Facilities: Providing compressed air for various production processes, pneumatic tools, and automation.

- Oil & Gas Industry: For gas compression in refineries, pipelines, and processing plants.

- Chemical and Petrochemical Plants: Supplying compressed air or process gas for critical reactions and operations.

- Power Generation: Used in certain power plant applications where large-scale compressed air is required.

- Food and Beverage: Supplying clean, compressed air for processing, packaging, and pneumatic systems.

- Wastewater Treatment: Aeration and other processes requiring compressed air.

Related Products:

The COOPER P3798102-00010 CN-UIM2 is an integral part of a larger compressor control system:

- Cooper Turbocompressor Vantage Control Panel: This is the complete control system enclosure that houses the UIM and the Main Logic Module (MLM).

- Cooper P3798102-00000 Main Logic Module (MLM) / CN-MLM2: This is the primary controller and I/O module within the Vantage panel that the UIM communicates with. It performs the actual control logic and interfaces with field sensors and actuators on the compressor.

- Cooper Turbocompressor Units: The actual mechanical compressor (e.g., Centac series) that the control system manages.

- Sensors and Actuators: Field devices like pressure transmitters, temperature sensors, flow meters, and control valves connected to the MLM.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922