الوصف

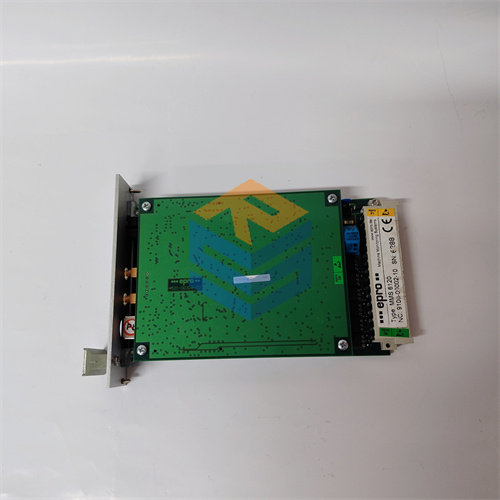

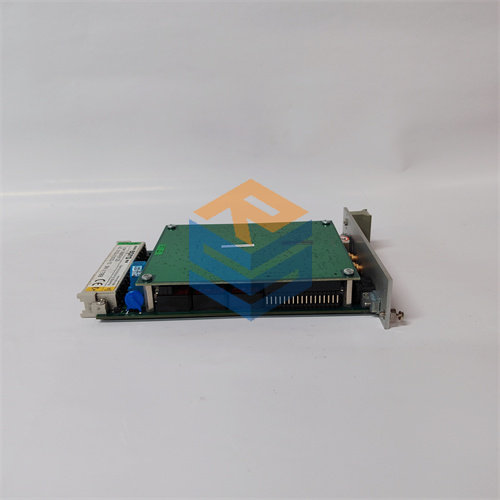

As an industrial automation expert, the EPRO MMS6120 9100-00002C-08 is a specific model of a dual-channel bearing vibration monitor within the EPRO MMS 6000 series, manufactured by EPRO (now part of Emerson Process Management).

This module is a critical component in machinery protection and condition monitoring systems, especially for rotating machinery in demanding industrial environments. It’s designed to continuously measure and analyze the vibration levels of bearings, which is crucial for predictive maintenance and preventing catastrophic equipment failures.

Let’s break down the key aspects of this module:

- EPRO: The original manufacturer, now part of Emerson. EPRO is known for its high-quality machinery protection and condition monitoring solutions.

- MMS 6000 Series: This indicates it’s part of a modular system. The MMS 6000 system often includes a system rack (like the IMR 6000 series), various monitor modules (like the MMS6120), logic cards, and interface cards, all working together to provide comprehensive machine health data.

- MMS6120: This is the specific monitor module type. It’s identified as a dual-channel bearing vibration monitor.

- 9100-00002C-08: This is the specific ordering or sub-model number, which defines its exact configuration and features. In this case, “9100-00002C-08” (or similar variations like 9100-00002) is a standard part number for the MMS6120.

Key Features and Benefits:

- Dual-Channel Monitoring: The MMS6120 can simultaneously monitor two independent vibration sensors (typically electrodynamic velocity sensors like EPRO PR 9266 or PR 9268 series, or piezoelectric sensors). This provides comprehensive insight into bearing health.

- Bearing Vibration Monitoring: Specifically designed to detect and analyze bearing vibrations, which are key indicators of bearing wear, misalignment, unbalance, and other mechanical faults.

- Predictive Maintenance: By continuously monitoring vibration levels, it helps identify potential issues early, allowing for scheduled maintenance, reducing unplanned downtime, and extending equipment lifespan.

- High Precision and Accuracy: Utilizes advanced sensor technology and signal processing algorithms to provide accurate and reliable vibration measurements.

- Alarm Functions: Features customizable alarm thresholds (Alert and Danger levels) for each channel. When vibration levels exceed these predefined limits, it triggers alerts, enabling timely intervention.

- Galvanic Isolation: Ensures electrical isolation between sensor inputs and the power supply, protecting against interference, ground faults, and maintaining data integrity in harsh industrial environments.

- Robust Design: Engineered for industrial use, it can withstand challenging conditions, including vibration, temperature fluctuations (typical operating range 0°C to +65°C), and humidity.

- Communication Interfaces: Often includes RS232/RS485 ports for local configuration and communication with higher-level systems, such as EPRO’s MMS 6850 Analysis System or other DCS/SCADA systems.

- Self-Checking Functions: Incorporates built-in self-test and extended self-checking functions, including sensor self-test, to ensure the module’s integrity and reliability.

- Redundant Power Supply Input: Some versions feature redundant power supply inputs for enhanced reliability.

Technical Specifications (Typical for MMS6120):

Typical Applications:

The EPRO MMS6120 is essential for monitoring and protecting critical rotating machinery in industries where reliable operation and early fault detection are paramount.

- Power Generation: Turbines (steam, gas, hydro), generators, pumps, fans.

- Oil and Gas: Compressors, pumps, gas turbines, and other rotating equipment in refineries, pipelines, and offshore platforms.

- Chemical and Petrochemical: Pumps, mixers, and compressors in process plants.

- Manufacturing: Large motors, gearboxes, and other production machinery.

- Pulp and Paper: Rollers, pumps, and other rotating equipment in paper mills.

- Water and Wastewater Treatment: Pumps and blowers.

It’s a core component in predictive maintenance programs, allowing operators to monitor machine health, schedule maintenance proactively, and prevent unexpected failures that could lead to costly downtime.

Related Products and Solutions:

The EPRO MMS6120 is part of a larger monitoring system. To implement a complete solution, you would typically integrate it with:

- EPRO MMS 6000 Series System Racks (e.g., IMR 6000/xx): These provide the physical housing, power supply, and backplane communication for the MMS6120 and other modules.

- EPRO Sensors:

- PR 9266 / PR 9268 Series: Electrodynamic velocity sensors (common for bearing vibration).

- PR 642X Series: Eddy current proximity sensors (for displacement, often used with other monitor modules like MMS6210 for shaft displacement).

- EPRO Power Supply Modules: To provide stable power to the system rack and modules.

- EPRO Interface Modules (e.g., MMS 6824 for Modbus, MMS 6825 for Ethernet TCP/IP): For communication with external DCS, SCADA, or asset management systems.

- EPRO Logic Cards (e.g., MMS 6720, MMS 6740): For implementing relay logic and safety functions based on monitor outputs.

- EPRO Configuration Software: For setting up measurement parameters, alarm levels, and communication settings.

- EPRO Analysis Systems (e.g., MMS 6850): Software platforms for advanced data analysis, trending, and diagnostic capabilities.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922