الوصف

Product Name:

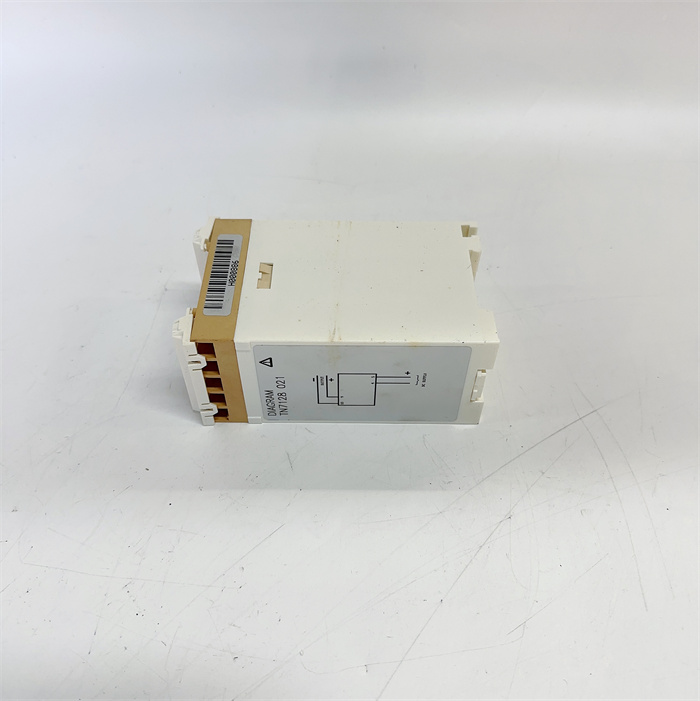

GEC ALSTHOM 3BE101 DCS PLC Module

Product Description:

The GEC ALSTHOM 3BE101 is a Distributed Control System (DCS) PLC module designed for integration into industrial control systems. This module is part of the GEC ALSTHOM (now GE Energy) product range, which is renowned for offering highly reliable automation and control solutions for various industrial applications. The 3BE101 module is typically used for interfacing and controlling different processes, ensuring precise monitoring, control, and automation in industries such as power generation, chemical processing, oil and gas, and manufacturing.

As a PLC (Programmable Logic Controller) module, the 3BE101 facilitates real-time control and automation, integrating seamlessly with the overall DCS system to handle complex control strategies. It is designed to process and interpret inputs, execute control algorithms, and output signals to manage industrial processes effectively.

Product Parameters:

- Model: 3BE101

- Type: PLC Module (DCS Integration)

- Manufacturer: GEC ALSTHOM (GE Energy)

- Function: Process control, automation, integration with DCS

- Application: Industrial process control in industries like power generation, oil & gas, chemical plants, and manufacturing.

- Interface: Digital and analog inputs/outputs

- Control: Real-time process control and monitoring

- Integration: Part of a larger Distributed Control System (DCS) for comprehensive process management

Product Specifications:

General Features:

-

Distributed Control:

The 3BE101 module is designed to operate in a distributed control environment, meaning it can communicate and function within a network of control modules across large industrial facilities, allowing decentralized control of processes. -

Programmability:

As a PLC, the module allows users to create and modify control programs for specific applications. The programming can be done using ladder logic or other standard PLC programming languages, enabling easy adaptation to different industrial processes. -

Input/Output Channels:

- The module is capable of handling digital and analog I/O signals.

- Supports analog input (e.g., 4-20mA signals) for monitoring variables like temperature, pressure, and flow rates.

- Handles digital inputs for binary signals (on/off) from switches, sensors, and other equipment.

-

Real-Time Control:

Provides real-time processing of control algorithms, ensuring that the system can react promptly to process changes, maintain stability, and ensure safety. -

Redundancy Support:

Designed with support for redundancy in mind, this module can work in tandem with backup systems to ensure high reliability and minimal downtime in critical applications. -

Communication Protocols:

The 3BE101 integrates with other control systems, sensors, and devices using standard industrial communication protocols such as MODBUS, HART, and Profibus, ensuring compatibility with various industrial equipment. -

Scalability:

The module is scalable, meaning additional modules can be added to expand the system as the needs of the plant grow.

Electrical Specifications:

-

Power Supply:

- Nominal Input Voltage: Typically 24 V DC for most industrial PLC modules.

- Power Consumption: Estimated to be around 5-10 watts, depending on the configuration and connected peripherals.

-

Inputs:

- Digital Inputs: Up to 16 digital inputs per module.

- Analog Inputs: 4-20mA current loop, typically up to 8 channels per module.

-

Outputs:

- Digital Outputs: Typically 16 outputs, capable of driving relays or other output devices.

- Analog Outputs: Capable of handling 4-20mA signals, typically up to 4 channels per module.

-

Signal Conditioning:

Provides internal signal conditioning to convert sensor inputs to a usable form for processing and control, ensuring data integrity and accuracy.

Mechanical Specifications:

-

Dimensions:

- Typically designed for 19-inch rack mounting, similar to standard industrial rack-mount modules.

- Height: 3.5 inches (approximately 89 mm)

- Width: 6.5 inches (approximately 165 mm)

- Depth: 10 inches (approximately 254 mm)

-

Weight:

- Typically 1.5-3 kg, depending on the specific configuration.

-

Mounting:

- Rack-mountable in 19-inch industrial control racks.

Environmental Specifications:

-

Operating Temperature Range:

- 0°C to 60°C (32°F to 140°F), typical for most industrial PLC modules.

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to 185°F).

-

Humidity:

- Operates in up to 95% relative humidity (non-condensing).

-

Vibration and Shock Resistance:

- Designed for typical industrial vibration levels and shock resistance, ensuring reliable operation in harsh industrial environments.

-

EMI/RFI:

- Compliant with electromagnetic interference (EMI) and radio-frequency interference (RFI) standards, ensuring minimal signal disruption in electrically noisy environments.

Key Benefits:

-

Enhanced Process Control:

The 3BE101 module helps to improve the control and automation of complex industrial processes. By providing real-time data processing and control, it ensures that operations are conducted efficiently and safely. -

Flexible Integration:

The module integrates well with various DCS, SCADA, and PLC systems, offering flexibility for upgrading and expanding control systems in existing industrial facilities. -

Reliability and Redundancy:

The GEC ALSTHOM 3BE101 module supports redundancy configurations to increase system reliability and reduce the chances of failure, especially in mission-critical operations. -

Scalable Architecture:

It allows for the expansion of the control system to manage larger or more complex facilities by adding more modules to the system. -

Programmable for Diverse Applications:

With its ability to run user-defined logic and control routines, the 3BE101 can be tailored to meet the specific needs of various applications across different industrial sectors.

Conclusion:

The GEC ALSTHOM 3BE101 DCS PLC Module is an integral component of modern industrial control systems. With its ability to handle digital and analog inputs/outputs, real-time processing, and seamless integration into distributed control environments, it provides an effective solution for controlling and automating industrial processes. Its scalability, flexibility, and support for redundancy make it suitable for a wide range of industries, including power generation, oil and gas, chemical processing, and manufacturing. The 3BE101 offers high reliability, easy integration, and long-term operational stability for mission-critical applications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922