الوصف

Product Name:

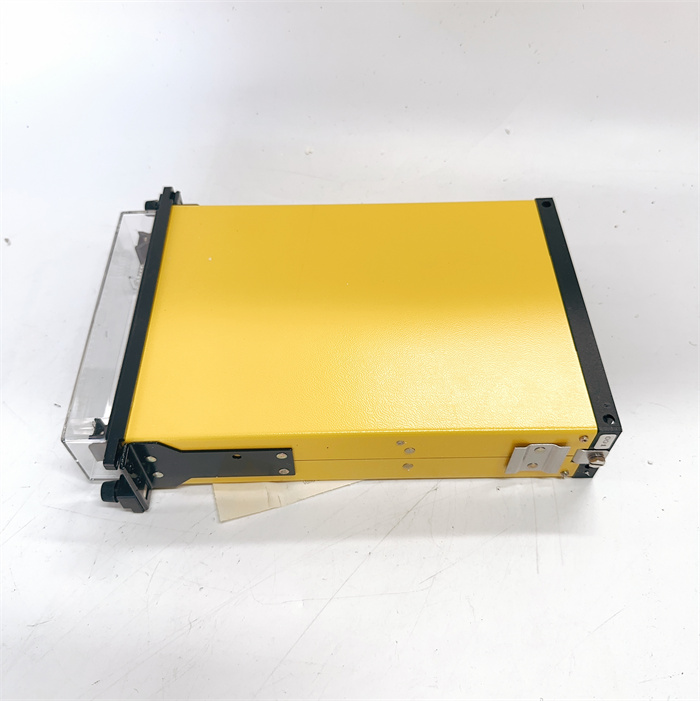

GEC ALSTHOM MVAX12B1DA0753A DCS/PLC Module

Product Description:

The GEC ALSTHOM MVAX12B1DA0753A is a DCS (Distributed Control System)/PLC (Programmable Logic Controller) module designed for advanced industrial automation applications. GEC ALSTHOM, now part of Alstom (and later integrated into General Electric (GE), after various mergers and acquisitions), has long been known for providing high-performance control systems for industries such as energy, power generation, oil & gas, and transportation.

The MVAX12B1DA0753A module is a part of the MVAX series, offering real-time process control, monitoring, and data communication for critical industrial processes. This module is designed for high-reliability environments where system uptime is crucial. It integrates seamlessly with GE’s DCS systems, providing flexible and efficient control capabilities.

This module is built to handle complex process control tasks and includes multiple I/O configurations, advanced diagnostics, and redundant operation options for increased system availability and fault tolerance.

Key Features:

- Real-Time Control & Monitoring: Capable of precise, real-time data acquisition and control for complex systems like power plants, chemical reactors, and energy management systems.

- High Reliability: Engineered for industries that require high availability, such as energy generation, oil & gas, and manufacturing.

- Redundancy: Supports redundant power supplies and I/O configuration to minimize the risk of failure.

- Modular Architecture: Offers flexibility for scaling systems to meet specific needs by adding or removing I/O modules.

- Advanced Diagnostics: Built-in self-diagnostics to detect faults and minimize downtime, ensuring efficient maintenance and high system reliability.

- Versatile I/O Options: Supports both digital and analog I/O, allowing integration of a wide variety of field devices.

- System Integration: Designed for compatibility with GE’s DCS control systems, facilitating smooth integration into large-scale industrial processes.

Product Parameters & Specifications:

1. General Specifications:

- Model: GEC ALSTHOM MVAX12B1DA0753A

- Type: DCS/PLC I/O Module

- Manufacturer: GEC ALSTHOM (now GE)

- Application: Suitable for industrial automation and process control in power generation, chemical industries, oil & gas, water treatment, and manufacturing systems.

- Control System Compatibility: Compatible with GE DCS systems (such as GE Mark VI, Mark VIe, Proficy iFIX, and Proficy Plant Applications).

- Functionality: Provides both digital and analog I/O for interfacing with field devices such as sensors, actuators, and control equipment.

- Modular Design: Supports modular expansion, allowing the system to scale according to specific project requirements.

2. Electrical Specifications:

- Operating Voltage: Typically operates on 24V DC, common in industrial control systems.

- Input Voltage Range: Designed to function at 24V DC with typical tolerances.

- Power Consumption: Power consumption varies, but typical ranges are between 10W to 50W, depending on I/O configuration.

- Signal Types:

- Digital Inputs/Outputs: 24V DC logic signals for digital control and monitoring.

- Analog Inputs: Typically supports 4-20mA or 0-10V signals for interfacing with field devices.

- Analog Outputs: Supports 4-20mA or 0-10V outputs for controlling actuators, valves, and other analog devices.

3. I/O Specifications:

- Digital Inputs: The module can support 16 to 64 digital inputs, depending on system configuration and requirements. These inputs are used for binary signals such as on/off switches, relays, or sensors.

- Digital Outputs: Supports 16 to 64 digital outputs for controlling actuators, relays, or other switching devices.

- Analog Inputs: 4-20mA or 0-10V for monitoring continuous signals from devices like pressure transmitters, temperature sensors, and flow meters.

- Analog Outputs: 4-20mA or 0-10V outputs for controlling actuators or modulating control devices.

- Communication I/O: Supports a variety of communication protocols such as Modbus RTU, Ethernet/IP, and HART.

4. Communication Protocols:

- Modbus RTU: Serial communication protocol widely used for integrating with other industrial systems and devices.

- Ethernet/IP: High-speed Ethernet communication protocol designed for real-time data exchange.

- Modbus TCP/IP: Supports Ethernet-based Modbus communication for integration into modern industrial Ethernet networks.

- HART Protocol: Allows for the communication with smart field devices, enabling two-way digital communication alongside the 4-20mA signal, providing access to additional device information.

- GE Mark VI Communication: Native support for GE Mark VI and other GE DCS systems, ensuring seamless integration.

5. Environmental Specifications:

- Operating Temperature Range: The module operates effectively in a temperature range from -20°C to 60°C (-4°F to 140°F).

- Storage Temperature Range: Can be stored in a temperature range of -40°C to 85°C (-40°F to 185°F).

- Humidity Range: Typically operates within 5% to 95% relative humidity, non-condensing.

- Vibration Resistance: Designed to withstand standard industrial vibration levels, typically up to 5g.

- Shock Resistance: Built to handle industrial shock levels, usually 10g.

- Ingress Protection: Typically IP20, providing basic protection against dust. Additional enclosures may be needed for full environmental protection.

6. Performance Specifications:

- Scan Time: Typical scan time for the module is 10ms to 100ms, ensuring real-time control and feedback.

- Processor Speed: Equipped with 32-bit or 64-bit processors for fast data processing and control.

- Memory: Typically comes with 512MB to 2GB of memory, sufficient to handle large-scale process control applications.

- Control Capacity: The module can manage up to 10,000 I/O points, depending on the configuration, making it suitable for large-scale applications.

- System Redundancy: Can be configured with redundant power supplies and I/O configurations for higher availability and fault tolerance.

7. Safety and Diagnostic Features:

- Self-Diagnostics: Includes real-time self-diagnostic tools to detect faults and issues early, helping to maintain operational efficiency and reduce unplanned downtime.

- Hot-Swap: Supports hot-swapping, which allows modules to be replaced without powering down the system, ensuring minimal disruption.

- Fault Detection: Built-in mechanisms for early fault detection, enabling faster responses and predictive maintenance.

- Redundant Power Supply: Supports redundant power supplies to ensure continuous operation in case of a power failure.

Application Examples:

- Power Generation: Used in power plants to control and monitor equipment such as turbines, generators, and transformers.

- Oil & Gas: Ideal for managing critical systems in refineries, pipelines, and offshore platforms.

- Chemical Processing: Utilized in chemical reactors, distillation columns, and other automated processes where high reliability is needed.

- Water Treatment: Provides control for water purification systems and distribution networks.

- Manufacturing: Applied in automated manufacturing lines, robotic control, and packaging systems.

Conclusion:

The GEC ALSTHOM MVAX12B1DA0753A DCS/PLC Module is a reliable, flexible, and scalable solution for industrial automation and process control. With its modular design, advanced diagnostics, and high reliability, it is suited for industries requiring real-time process control and high availability. Its compatibility with GE DCS systems and support for multiple communication protocols make it ideal for critical infrastructure in industries like power generation, chemical processing, and oil & gas.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922