الوصف

Product Name:

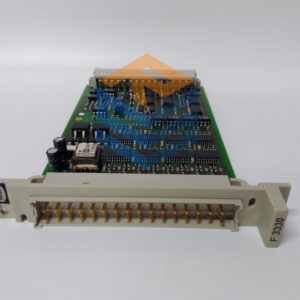

HIMA F3 AIO 8/4 01 DCS PLC Module

Product Description:

The HIMA F3 AIO 8/4 01 is a versatile and reliable Distributed Control System (DCS) / Programmable Logic Controller (PLC) module designed by HIMA for industrial process automation. This module is part of the F3 series, a line of high-performance control modules renowned for their safety and reliability in critical applications. The F3 AIO 8/4 01 module features 8 digital inputs (DI) and 4 analog outputs (AO), providing comprehensive functionality for monitoring, controlling, and optimizing complex industrial systems.

HIMA’s F3 AIO 8/4 01 module is specifically designed for industries that demand high safety standards and real-time control, such as chemical plants, oil & gas, power generation, and pharmaceutical manufacturing. It offers seamless integration with HIMA’s F3 safety controllers, providing advanced features for safety-critical applications, including fault tolerance, redundancy, and continuous system monitoring.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

- Manufacturer: HIMA

- Model/Part Number: F3 AIO 8/4 01

- Series: HIMA F3 Series

Input/Output Configuration:

- Digital Inputs (DI): 8 channels for receiving discrete signals from sensors, switches, or field devices.

- Analog Outputs (AO): 4 channels to control continuous devices such as actuators, valves, or variable-speed drives.

- Digital Output: Typically connected to field devices for controlling actuators, relays, and other switching elements (specific details not provided for this model, though typically these modules include digital outputs).

Communication Protocols:

- Fieldbus Integration: The HIMA F3 AIO 8/4 01 module is compatible with HIMA’s F3 system, integrating into both standard control networks and safety-critical systems.

- Modbus: Integration with Modbus RTU and Modbus TCP protocols for industrial communication.

- PROFIBUS/PROFINET: Often supports PROFIBUS or PROFINET for communication between the F3 controller and other automation equipment.

- Ethernet: Typically provides Ethernet/IP support for high-speed communication within Ethernet-based networks.

Control and Performance:

- Real-Time Processing: Provides real-time control and data acquisition, crucial for handling time-sensitive processes.

- Processing Speed: Optimized for high-speed processing to ensure fast responses in automation and control systems.

- Response Time: Very low latency for time-critical operations in industries where fast reaction times are essential.

Power Supply:

- Operating Voltage: Typically 24 V DC or 48 V DC (depending on the configuration).

- Power Consumption: Low power consumption suited for industrial automation applications.

Environmental Specifications:

- Operating Temperature: Typically -20°C to +60°C (-4°F to 140°F), capable of operating in harsh industrial environments.

- Storage Temperature: -40°C to +85°C (-40°F to 185°F).

- Humidity: Works within a 5% to 95% relative humidity range (non-condensing).

- Vibration Resistance: Built to withstand typical industrial vibrations and shocks, meeting industrial standards for ruggedness.

Redundancy & Reliability:

- Redundant Power Supply: The module supports redundant power supply configurations for enhanced system availability and reliability.

- Fail-Safe Operation: Features fail-safe mechanisms ensuring system integrity during power or hardware failure scenarios.

Safety & Compliance:

- Safety Integrity Level (SIL): Designed for SIL 3 applications, ensuring high levels of safety for mission-critical processes in industries such as oil & gas, chemicals, and power generation.

- Standards: Complies with safety standards such as IEC 61508, IEC 61511, and ISO 13849, making it ideal for safety-critical industrial applications.

- Certifications: Typically complies with CE, UL, and other global standards for industrial and safety systems.

Software & Programming:

- Programming Environment: Configured and programmed through HIMA’s F3 configuration and engineering software.

- Programming Languages: Supports IEC 61131-3 programming standards, including Ladder Logic (LD), Structured Text (ST), and Function Block Diagram (FBD).

- Diagnostic Tools: Built-in diagnostics and monitoring tools enable quick detection of faults and system issues, ensuring fast troubleshooting.

Diagnostics & Monitoring:

- LED Indicators: Provides LED status indicators for monitoring the operational status of the module, facilitating real-time diagnostics.

- Self-Diagnostics: The module performs self-diagnostics to monitor its health and reliability, alerting operators to potential issues.

- Alarms and Alerts: Capable of generating alarms and alerts when system conditions reach critical levels.

Key Features & Benefits:

-

High-Safety Standards:

- The F3 AIO 8/4 01 module is designed for high safety integrity levels (SIL 3), making it ideal for industries with critical safety requirements, such as chemical, oil & gas, and power generation.

-

Modular and Scalable:

- It is part of the F3 series, allowing easy scalability for larger or more complex systems by adding additional modules as required.

-

Real-Time Control:

- Real-time control capabilities ensure the module is well-suited for time-sensitive processes, offering fast reaction times and reliable operation.

-

Versatile I/O:

- With 8 digital inputs and 4 analog outputs, the module is highly versatile, supporting a wide variety of field devices and controllers.

-

Redundancy and Fault Tolerance:

- With redundant power and fail-safe features, this module ensures high system availability and minimizes downtime, even in critical applications.

-

Comprehensive Diagnostics:

- Built-in diagnostics and monitoring functions allow operators to track system performance in real time, offering enhanced fault detection and quick troubleshooting.

-

Global Compliance:

- Compliance with industry standards like CE, UL, IEC, and ISO makes it suitable for use in various regions and sectors worldwide.

Applications & Use Cases:

- Chemical Processing: Monitoring and controlling complex chemical processes where safety and precision are paramount.

- Oil & Gas: Automation and safety-critical monitoring in upstream, midstream, and downstream operations, including refineries and pipelines.

- Power Generation: Managing and controlling power plants, turbines, electrical distribution systems, and backup systems.

- Pharmaceutical Manufacturing: Automation in drug production and quality control processes where precision and safety are crucial.

- Water Treatment: Control systems for monitoring and automating water purification, distribution, and wastewater treatment plants.

Conclusion & Recommendation:

The HIMA F3 AIO 8/4 01 DCS PLC Module is an ideal solution for safety-critical industrial applications requiring real-time control, high reliability, and seamless integration with safety systems. With its advanced diagnostics, redundancy options, and compliance with industry standards, this module is a robust choice for sectors such as oil & gas, chemical processing, pharmaceuticals, and power generation. The modular nature of the F3 series also allows for flexibility and scalability as your system needs evolve.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922