الوصف

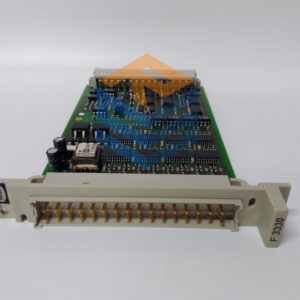

HIMA 985210211 X-CPU 01 DCS PLC Module

Here’s a detailed overview of the HIMA 985210211 X-CPU 01 DCS PLC module:

Product Name:

HIMA 985210211 X-CPU 01

Product Description:

The HIMA 985210211 X-CPU 01 is a critical module within HIMA’s HI-UX safety and control systems. The X-CPU 01 is an essential component of the HI-UX safety controller platform, widely used in industrial process control systems where high reliability and safety are paramount, such as in process automation, oil and gas, chemical industries, and nuclear power plants.

As part of the HIMA X-series, the 985210211 X-CPU 01 provides advanced safety control capabilities, including redundant processing, integrated diagnostics, and fail-safe operation, meeting the highest safety standards for hazardous processes. It’s designed for SIL 3 (Safety Integrity Level) rated applications, making it one of the most trusted modules for critical systems requiring high availability and fault tolerance.

The X-CPU 01 is designed for real-time control and monitoring of complex industrial systems, ensuring safety and reducing downtime through a robust and high-performing processing unit.

Product Parameters & Specifications:

- Model: 985210211 X-CPU 01

- Brand: HIMA

- Module Type: X-CPU 01 (Central Processing Unit for Safety and Control)

- Application: Distributed Control Systems (DCS) and Safety Instrumented Systems (SIS)

- Safety Standard: SIL 3 (Safety Integrity Level 3)

- Redundancy: Dual-channel processing for fault tolerance and high availability

- Real-Time Processing: Supports real-time data acquisition and control functions for industrial processes

- CPU Type: 32-bit Microprocessor

- Control System: HI-UX (HIMA Safety Platform)

- Communication Protocols:

- Modbus TCP

- PROFIBUS DP

- Ethernet/IP

- HIMA-specific protocols

- Power Supply: Typically powered by 24V DC

- Mounting Type: Rack-Mounted or Modular System Integration

- Temperature Range:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F)

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95% RH (non-condensing)

- Memory: On-board memory with support for high-speed data logging and program storage

- Diagnostics: Advanced self-diagnostics for system health monitoring

- Safety Features:

- Integrated Redundancy: Dual CPU architecture for high availability

- Integrated Diagnostics: Continuous monitoring of the system’s health and real-time fault detection

- Safe State Recovery: Ensures the system can return to a safe state after fault detection

- Standards Compliance:

- IEC 61508 (Functional Safety)

- IEC 61511 (Functional Safety for the Process Industry)

- IEC 61513 (Safety for Nuclear Power Plants)

- ISO 13849 (Safety for Machinery)

Advantages & Features:

-

High Safety Standards (SIL 3):

- The 985210211 X-CPU 01 module meets SIL 3 requirements, which is the highest safety level for industrial safety systems. It ensures that the control and monitoring processes meet the strictest standards for risk reduction.

-

Redundant Architecture:

- The dual-channel redundancy in the CPU ensures fault tolerance and high system availability. If one processing channel fails, the other continues operation without interruption.

-

Real-Time Control:

- It provides real-time control and decision-making, critical for high-speed processes such as those found in oil & gas, chemical processing, and power generation.

-

Comprehensive Diagnostics:

- Continuous system self-checks and diagnostics provide immediate detection of any faults in the system, reducing downtime and maintenance costs. It also offers predictive diagnostics, giving operators an early warning of potential issues before they lead to failures.

-

Flexible Integration:

- It supports a wide range of communication protocols including Modbus TCP, PROFIBUS DP, and Ethernet/IP, ensuring easy integration into diverse industrial networks.

-

Enhanced Reliability:

- The module is designed to operate in harsh environments, with extended temperature and humidity ranges, ensuring continuous operation in challenging conditions.

-

Scalable:

- This CPU module can be easily integrated into larger safety control systems, allowing for scalable, customizable solutions to meet the needs of different industrial processes.

Applications:

The HIMA 985210211 X-CPU 01 module is used across various industries, including:

-

Oil & Gas:

- Critical safety and control of pipelines, refineries, and offshore platforms, where the failure of safety systems can lead to catastrophic consequences.

-

Chemical & Petrochemical:

- Managing complex chemical processes that require continuous monitoring, control, and real-time safety enforcement to avoid hazardous situations.

-

Power Generation:

- Ensuring the safety and efficiency of power plants, including both conventional and renewable energy sources, by controlling turbines, boilers, and generators.

-

Nuclear Industry:

- With its SIL 3 certification, it meets the stringent requirements for nuclear power plants, ensuring the safety of reactors and other critical systems.

-

Process Automation:

- Applied in any environment that requires a high degree of safety and control, such as food and beverage, automotive, and other heavy manufacturing sectors.

Comparison with Competing Products:

The HIMA 985210211 X-CPU 01 is a highly specialized and robust safety CPU module designed for industries where safety, redundancy, and real-time processing are non-negotiable. Compared to competitors like Siemens or Honeywell safety systems, the X-CPU 01 offers:

- Superior safety certifications like SIL 3, which meets the most demanding regulatory requirements.

- Integrated redundancy for fault-tolerant operation, making it a reliable choice for critical applications.

- Better diagnostics and system health monitoring, which helps to minimize downtime and increase system uptime.

Competitors may offer similar safety systems but may not match the level of real-time performance, redundant processing, and diagnostic features offered by the 985210211 X-CPU 01.

Selection Tips:

- Compatibility: Ensure that the X-CPU 01 is compatible with other modules in your HIMA system, especially in terms of communication protocols and system integration.

- Environmental Conditions: Verify that the operating conditions meet the temperature and humidity specifications for reliable performance.

- Safety Requirements: Confirm that the SIL 3 safety level is appropriate for your application’s risk profile and regulatory compliance needs.

For more details or support, you can reach out to HIMA’s authorized distributors or consult their website for documentation and guidance on the installation and configuration of the X-CPU 01.

Let me know if you need further details or help with other modules!

6ES7 522-1BL10-0AA0 PLC

DSQC661 3HAC026253-001 PLC

191920-T14 PLC

3500\32\BENTLY plc

REF542PLUS plc

apc3322a PLC

Synrad 48-1KWL

YPP105F PLC

ICSI16E1 PLC

EA9-T6CL-R PLC

FBM215 PLC

3HAC028357-001 DSQC 679 PLC

2711-T10G20 PLC

PFTL101A 0.5KN 3BSE004160R1 PLC

51305072-100 PLC

IC695CRU320-CD PLC

A05B-2518-C204 PLC

P0922AG or P0922AE GCIO FOXBORO PLC

CP10G-04-0045 PLC

HART 475 PLC

CACR-SR30SB1 DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922