الوصف

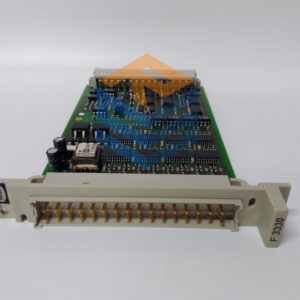

HIMA F8620/11 DCS/PLC Module

Product Name:

HIMA F8620/11 DCS/PLC Module

Product Description:

The HIMA F8620/11 is a high-performance DCS (Distributed Control System) and PLC (Programmable Logic Controller) module designed for safety-critical industrial applications. It is part of HIMA’s family of safety systems, built to meet stringent safety standards like SIL (Safety Integrity Level) 3 and IEC 61508. The F8620/11 is designed to handle complex, mission-critical processes where high reliability, precision, and safety are paramount.

The F8620/11 module is engineered to provide reliable real-time control, fault-tolerant operation, and integrated diagnostics, making it suitable for industries such as chemical processing, oil and gas, power generation, and industrial automation. The module offers a flexible, modular design, allowing it to be tailored to specific requirements and easily integrated with other components of the HIMA SIL3-compliant safety system.

It is widely used for applications requiring continuous monitoring, alarm handling, emergency shutdown systems (ESD), and process control, ensuring that industrial processes can be operated safely and efficiently.

Key Features:

-

SIL 3 Certification:

- Meets the highest safety standards for critical systems, ensuring compliance with IEC 61508 and IEC 61511 for functional safety.

-

High Availability and Fault Tolerance:

- Features redundant processing and communication paths for continuous system operation even in case of a component failure, ensuring minimal downtime.

-

Real-Time Data Processing:

- Capable of handling high-speed, real-time control tasks, including data acquisition, signal processing, and decision-making for critical processes.

-

Integrated Diagnostics:

- Built-in self-diagnostics for detecting faults and degradation of system components, enabling quick identification and resolution of issues.

-

Communication Flexibility:

- Supports multiple communication protocols for seamless integration with existing control systems and field devices, including Ethernet, Modbus, Profibus, and HART.

-

Modular Design:

- The F8620/11 module is modular, allowing for flexible configuration, expansion, and integration with other control systems as needed.

-

Safety and Emergency Shutdown (ESD):

- Includes fail-safe features for safe shutdown procedures in case of emergencies, ensuring that hazardous situations are managed effectively.

-

Wide Application Range:

- Ideal for industries such as petrochemicals, oil and gas, power generation, water treatment, and other process industries requiring high levels of safety and reliability.

-

Fieldbus Integration:

- Supports fieldbus technologies like Profibus DP, Modbus TCP, and Hart, enabling it to communicate with various field devices, controllers, and SCADA systems.

-

Customizable Program Logic:

- Flexible programming options, supporting Ladder Logic, Structured Text, and Function Block Diagram for easy configuration and control programming.

Product Parameters and Specifications:

General Specifications:

- Product Name: HIMA F8620/11 DCS/PLC Module

- Manufacturer: HIMA Paul Hildebrandt GmbH

- Series: F8600 Safety PLC Series

- Safety Integrity Level (SIL): SIL 3 (for both hardware and software)

- System Type: Safety PLC / DCS Module

- Type: Process Control and Safety Module

- Certification: IEC 61508 (SIL 3), IEC 61511, ATEX (for hazardous areas), UL (for industrial applications)

Power and Electrical Requirements:

- Input Voltage: 24V DC (nominal)

- Power Consumption: Typically between 10W to 25W (depending on configuration)

- Redundant Power Supply: Supports dual, redundant power supplies for increased reliability in critical applications.

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Relative Humidity: 5% to 95% (non-condensing)

- Vibration: Designed to meet industrial standards for vibration resistance.

I/O Configuration:

- Analog Inputs: Supports 4-20mA, 0-10V, and other industry-standard analog input signals for process measurement.

- Digital Inputs/Outputs: Discrete signals for on/off control, suitable for controlling actuators such as valves, motors, and alarms.

- Relay Outputs: Can drive high-power devices directly like solenoids, alarms, or emergency shutdown systems.

- High-Speed I/O: Capable of high-speed data acquisition for critical processes such as turbine control or flow measurement.

- Redundant I/O: Redundant I/O modules can be configured to ensure fault tolerance and high availability.

Communication and Networking:

- Ethernet: Ethernet/IP for communication with SCADA, HMI, and other control systems.

- Modbus RTU/TCP: For communication with other controllers, sensors, and systems.

- Profibus DP: Industry-standard fieldbus for communication with field devices and sensors.

- HART: Support for HART protocol for smart devices and field instruments.

- Redundant Communication Paths: Dual Ethernet ports and communication links for fault-tolerant networking.

Programming and Configuration:

- Programming Languages: Supports Ladder Logic, Structured Text, Function Block Diagram (IEC 61131-3 standard).

- Software Tools: Configuration and programming via HIMA’s Safety System Software, which provides graphical configuration, diagnostics, and system monitoring tools.

- Program Storage: Onboard program storage (with memory protection) to ensure reliable execution of control logic even during power failures.

Diagnostics and Maintenance:

- Self-Diagnostics: Built-in diagnostics for system health monitoring, error detection, and fault isolation.

- Event Logging: Records system events, faults, and operational data for detailed analysis and troubleshooting.

- Maintenance Alerts: Automatic alerts for preventative maintenance to avoid unexpected system downtime.

Environmental Specifications:

- Operating Conditions: Suitable for use in industrial environments subject to moderate vibrations, dust, and humidity.

- Protection Class: Typically IP20 or higher, with additional protection available for more extreme environments (e.g., IP65 for outdoor use).

Safety and Protection:

- Emergency Shutdown (ESD): Supports automatic system shutdown for hazardous situations to prevent damage or accidents.

- Redundancy: Dual processors and communication paths for high availability and fault tolerance.

- Overload Protection: Includes internal protection against overcurrent, short circuits, and communication overloads.

Applications:

-

Chemical Processing:

- For safety monitoring, emergency shutdown systems (ESD), and process control in chemical plants.

-

Oil and Gas:

- Critical for controlling processes in oil refineries, pipelines, and offshore platforms, ensuring safe and reliable operations.

-

Power Generation:

- Used in nuclear, thermal, and hydroelectric power plants for safety monitoring, turbine control, and fault detection.

-

Petrochemical:

- Ensures safe control of hazardous processes, such as distillation, cracking, and polymerization.

-

Pharmaceutical and Food & Beverage:

- Applied in manufacturing processes to ensure product quality, safety, and compliance with regulations.

-

Water Treatment:

- Ensures safe and efficient operation in municipal water treatment plants, including chemical dosing and flow control.

-

Other Critical Industries:

- Suitable for any industry requiring highly reliable, fault-tolerant, and safe control systems.

Conclusion:

The HIMA F8620/11 DCS/PLC Module is a high-performance, SIL 3-certified safety controller designed for safety-critical applications in industries like chemical, oil and gas, power generation, and more. With its robust fault-tolerant architecture, flexible communication protocols, and integrated diagnostics, the F8620/11 offers a reliable and scalable solution for process control and safety management. Whether used in emergency shutdown systems, process automation, or safety monitoring, the F8620/11 ensures continuous, safe, and efficient operations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922