الوصف

The ICS TRIPLEX+9832 is part of the ICS Triplex family of Distributed Control System (DCS) modules, which are widely used in safety-critical and high-availability industrial automation systems. These modules are designed to handle complex processes in industries such as power, oil and gas, and chemical processing, ensuring operational safety and reliability.

Product Name:

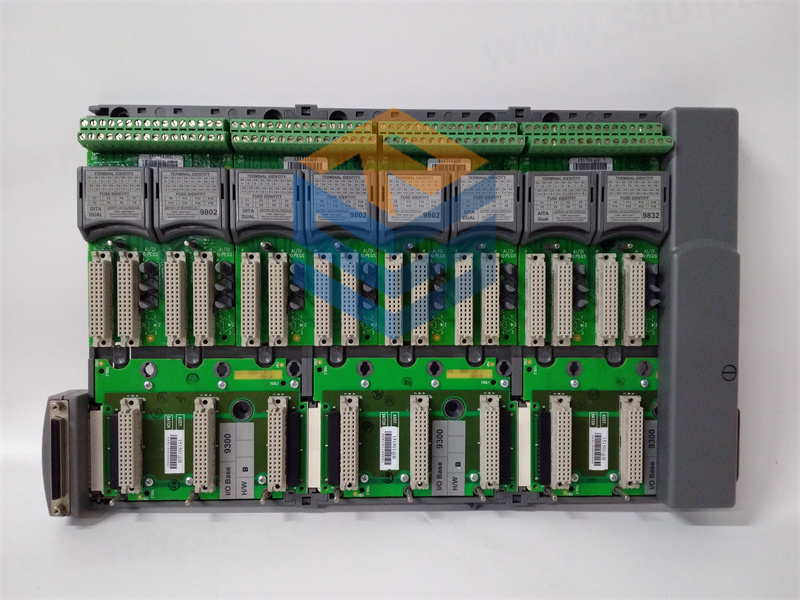

ICS TRIPLEX+9832 DCS PLC Module

Product Description:

The ICS TRIPLEX+9832 is a DCS PLC (Programmable Logic Controller) module designed for high-performance process control in critical applications. It is part of the ICS Triplex+ series, which is a robust platform for process automation, safety, and control. The 9832 module typically serves as an interface between the field devices and the control system, providing reliable control and monitoring of processes, equipment, and machinery in industries where safety and system uptime are paramount.

This module is designed with built-in redundancy and fault-tolerant features to ensure continuous operation, even in the event of component failure. Its advanced diagnostics, integrated testing, and certification features make it ideal for use in industries with stringent safety standards and critical operations.

Product Parameters & Specifications:

General Specifications:

- Module Type: PLC/DCS Interface and Control Module

- Part Number: 9832

- System Type: ICS Triplex+ Series (Advanced Distributed Control System for critical safety and process control)

- Function: Real-time control and monitoring, interfacing with field I/O devices (e.g., sensors, actuators, etc.)

- Field I/O Compatibility: Supports both analog and digital I/O signals, interfacing with external field devices for data acquisition and control.

- Control Features: Handles process logic, monitoring, diagnostics, and fault detection.

Key Parameters:

- Redundancy: Built-in fault tolerance and redundancy mechanisms for continuous operation. Ensures high availability and uptime, especially in critical control loops.

- Processing Power: High-performance processing for real-time data processing, with a fast response time for automation and control.

- Communication Protocols:

- Modbus TCP/IP

- Ethernet/IP

- Profibus

- Profinet

- IEC 61850 (optional depending on configuration)

- Fieldbus protocols like HART are also supported in certain configurations.

- Operating Voltage: Typically 24V DC for field devices and AC options may also be available.

- Operating Temperature: Typically operates within a range of 0°C to 60°C (32°F to 140°F), with options for extended temperature ranges in rugged industrial environments.

- Environment: Designed for harsh environments, including shock, vibration, electromagnetic interference (EMI), and extreme humidity.

- Certifications:

- UL (Underwriters Laboratories)

- CSA (Canadian Standards Association)

- CE (European Conformity)

- Ex-rated for hazardous environments (depending on configuration).

Fault Tolerance and Diagnostics:

- Diagnostics: Comprehensive diagnostic capabilities for real-time status, alarms, and fault detection, enabling predictive maintenance and fast troubleshooting.

- Redundancy: Includes hot-standby redundancy, ensuring that the system remains operational even if one module or part of the control system fails.

- Self-Test Capabilities: The module includes self-diagnostic features for real-time health checks, ensuring system integrity.

Field I/O Integration:

- Analog I/O: Supports integration with standard analog input/output devices for variables like pressure, temperature, and flow.

- Digital I/O: Interfaces with digital signals, such as discrete on/off switches or relays.

- Smart I/O Devices: Compatible with intelligent field devices like smart sensors, actuators, and variable frequency drives (VFDs).

Redundancy Features:

- Dual-CPU Architecture: The module features a dual-CPU setup, allowing for a fault-tolerant configuration where one CPU is active while the other is on standby.

- Power Supply Redundancy: The system can be configured with redundant power supplies to ensure that the system stays online even if one power source fails.

- Network Redundancy: Offers redundant communication paths for continuous operation, even in the event of a network failure.

Safety and Reliability:

- SIL-3 Certified: The ICS Triplex+9832 module is typically certified for SIL-3 (Safety Integrity Level 3) applications, meaning it is highly reliable and meets rigorous safety standards, making it suitable for use in safety-critical applications.

- Fail-Safe Operation: Ensures fail-safe operation in the event of a hardware failure, keeping critical processes under control.

User Interface and Software:

- Configuration and Programming: The module is typically programmed using ICS Triplex configuration and engineering tools, which are designed to make system setup, diagnostics, and troubleshooting easy and efficient.

- Integration: Seamlessly integrates with other ICS Triplex modules and third-party devices or systems, ensuring scalable and flexible automation solutions.

- Human-Machine Interface (HMI): Compatible with external HMI systems for real-time monitoring, visualization, and control of the automation process.

Summary:

The ICS TRIPLEX+9832 DCS PLC Module is designed for use in high-performance, safety-critical applications that require robust redundancy, fault tolerance, and reliable communication. With a range of diagnostics, redundant architectures, and compliance with safety standards such as SIL-3, it is ideal for industries such as oil & gas, power generation, and chemical processing, where process uptime and safety are paramount.

Would you like more detailed information on any of the module’s specific features or applications? Let me know!

T8232 Power Pack ICS TRIPLEX

ICS Triplex ICS trusted T8231C ICS TRIPLEX

ICS trusted T8231 ICS TRIPLEX

T8230 Power Shelf ICS TRIPLEX

T8225 Power Supply Module ICS TRIPLEX

Rockwell ICS Triplex T8222 ICS TRIPLEX

T8220 Power Supply Module ICS TRIPLEX

T8202 I/O Power Supply Chassis ICS TRIPLEX

T8200 I/O Power Supply Chassis ICS TRIPLEX

T8194 Shroud Kit ICS TRIPLEX

ICS trusted T8193

Rockwell ICS Triplex T8193

T8192 Shield ICS TRIPLEX

T8191 Shield ICS TRIPLEX

T8162 CS300 Bridge Module ICS TRIPLEX

ICS Triplex T8161

Rockwell ICS Triplex T8160

ICS trusted T8153 Communications

T8151C Communication Interface T8151B

T8123 Processor Interface Adaptor

T8122 Processor Interface Adaptor ICS TRIPLEX

ICS Triplex T8121

T8120 Processor Interface Adaptor ICS TRIPLEX

T8110C Processor

Rockwell ICS Triplex T8110B

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922