الوصف

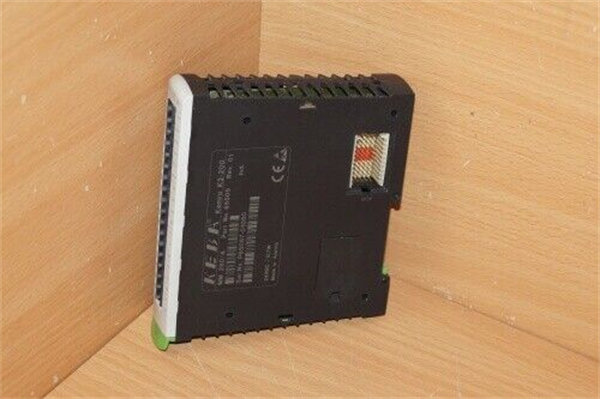

KEBA MM240A Vision Controller DCS PLC Module

Product Name:

KEBA MM240A Vision Controller DCS PLC Module

Product Description:

The KEBA MM240A Vision Controller is a high-performance, integrated PLC module designed for industrial automation systems, particularly in the areas of machine vision and process control. Combining the power of a programmable logic controller (PLC) with sophisticated vision system capabilities, the MM240A enables real-time processing and decision-making in production lines, robotics, quality control, and other automated applications.

The MM240A module is part of KEBA’s MM series, and it offers an innovative approach to automation where machine vision and control systems are seamlessly integrated into a single module. This combination enhances the overall efficiency of systems, reduces the complexity of installations, and provides a robust solution for demanding industrial applications, ensuring precise control, monitoring, and feedback loops for automated processes.

It is particularly well-suited for environments requiring high-speed image processing and decision-making, such as quality control in manufacturing, robotic guidance, and automated inspection systems. The module allows for advanced image processing algorithms, object recognition, positioning, and inspection functions, making it ideal for complex automation tasks that require both vision and control in one platform.

Key Features & Advantages:

-

Integrated Vision and Control: Combines a high-speed PLC with powerful machine vision capabilities, enabling automated tasks such as object detection, quality inspection, and sorting.

-

Advanced Image Processing: Supports various image processing algorithms and functions like edge detection, pattern recognition, defect detection, and color analysis.

-

Real-Time Processing: The system ensures fast decision-making and real-time feedback for time-critical applications, essential in high-speed production environments.

-

Flexible I/O Integration: Offers seamless integration with other I/O modules and sensors in the system, facilitating both vision-based feedback and control actions.

-

Programmable Logic Control (PLC) Functionality: Features full PLC capabilities, including ladder logic, structured text, and function block programming, giving engineers flexibility in programming and configuration.

-

Modular and Scalable: The MM240A can be easily expanded with additional modules for added I/O points, cameras, or sensors, enabling it to scale as the complexity of your automation system increases.

-

Industrial Protocol Support: Includes compatibility with industrial communication protocols such as Ethernet/IP, PROFINET, and Modbus, ensuring integration with a wide range of devices and controllers.

-

High-Speed Processing: Optimized for processing large volumes of data from vision systems, providing fast feedback and minimizing delays in automated systems.

-

Durable Design: Designed to withstand industrial environments with high reliability, including options for DIN rail mounting for easy installation and maintenance.

-

User-Friendly Interface: Features an intuitive software interface for programming, configuration, and monitoring of both PLC functions and vision tasks.

Product Parameters & Specifications:

-

Part Number: KEBA MM240A Vision Controller DCS PLC Module

-

Controller Type:

- Integrated PLC with advanced Machine Vision capabilities.

- Programmable for custom logic and vision-based operations.

-

Input Voltage:

- 24V DC (typical industrial control voltage).

-

Power Consumption:

- Typically 15-25W, depending on the system load and connected devices.

-

Processor:

- High-speed processor optimized for real-time image processing and automation tasks.

- Supports multi-threaded operations for both control and vision tasks.

-

Memory:

- RAM: Typically 2GB or more for fast processing of vision data.

- Storage: Flash storage of up to 8GB, with the ability to store images, programs, and configuration files.

-

Vision System Capabilities:

- Camera Support: Interfaces with high-resolution cameras for real-time image capture.

- Image Processing Algorithms: Includes advanced functions like pattern recognition, OCR (optical character recognition), barcode reading, 3D object scanning, and defect detection.

- Frame Rate: Capable of processing up to 60 frames per second (FPS), ensuring rapid real-time analysis.

-

I/O Capacity:

- Digital Inputs/Outputs: Supports up to 32 digital inputs and 32 digital outputs, depending on the configuration.

- Analog Inputs/Outputs: Supports 16 analog inputs and 8 analog outputs for precise control of process variables.

-

Communication Ports:

- Ethernet: Supports Ethernet/IP, PROFINET, and Modbus TCP for network communication.

- Serial Ports: RS-232/RS-485 for communication with external devices.

- USB Ports: For external device connection and programming.

- I/O Expansion: Can interface with additional I/O modules or vision equipment.

-

Software & Programming:

- Programming Environment: The MM240A supports various programming languages, including Ladder Logic, Structured Text, and Function Block Diagrams (FBD), enabling flexibility for users with different skill sets.

- Vision Programming Tools: Integrated vision software for configuring and tuning machine vision tasks, including object detection, inspection, and sorting.

-

Environmental Conditions:

- Operating Temperature: 0°C to 55°C (wide temperature range for industrial environments).

- Storage Temperature: -20°C to 70°C.

- Relative Humidity: 5% to 95%, non-condensing.

-

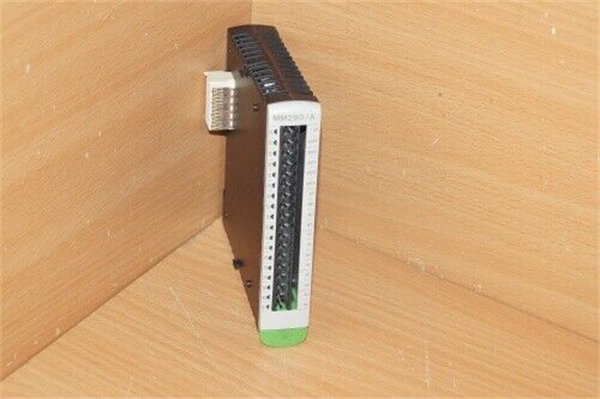

Mounting:

- DIN Rail Mounting: Easy installation on standard 35mm DIN rails for industrial applications.

-

Dimensions:

- Size (W x H x D): 160mm x 130mm x 100mm (compact design for easy integration into control cabinets).

- Weight: Approx. 1.2 kg.

-

Certification:

- CE Marked: Complies with European safety and electromagnetic compatibility standards.

- UL Listed: Meets Underwriters Laboratories safety standards.

- ISO 9001: Manufactured according to quality management standards.

Applications and Use Cases:

-

Machine Vision and Quality Control: Used in high-speed manufacturing and assembly lines for visual inspections, defect detection, and part sorting.

-

Robotics and Automated Guidance: Guides robotic arms in tasks like pick-and-place, welding, and assembly, using visual feedback for precise positioning and control.

-

Packaging and Sorting: In applications such as automated packaging, sorting, and labeling, the MM240A performs vision-based inspections to ensure products meet quality standards.

-

Automated Inspection Systems: In industries like automotive manufacturing, electronics, and pharmaceuticals, it checks for defects, measurements, and position verification of products.

-

Logistics and Warehouse Automation: Used in automated material handling systems for object recognition, barcode reading, and inventory tracking.

-

Food & Beverage Industry: Ensures product integrity, detects foreign objects, checks labels, and verifies packaging in production lines.

-

Pharmaceuticals: Used for automated inspection of packaging, labeling, and ensuring product quality standards.

-

Process Control Systems: Provides feedback to DCS (Distributed Control Systems) in complex manufacturing environments.

Comparison with Competitors:

The KEBA MM240A is designed to offer both high-performance PLC functionality and advanced machine vision capabilities. It offers better integration, easier installation, and scalability compared to many competitors in the market, such as Siemens‘ S7-1500 or Beckhoff’s CX5140.

The KEBA MM240A’s combination of vision and control makes it a unique solution for industrial automation tasks that require both real-time decision-making and visual inspection in one unit.

Let me know if you need more details or help with any other inquiries!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922