الوصف

Product Name:

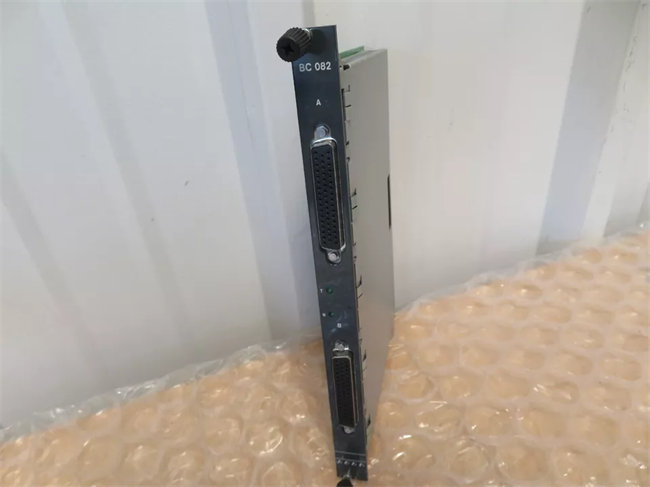

KEBA Ready Robotics Forge OS Developer Kit Block 1 with KEBA Controller (DCS PLC Module)

Product Description:

The KEBA Ready Robotics Forge OS Developer Kit Block 1 with KEBA Controller is a cutting-edge solution designed for robotic automation and industrial control systems. This kit combines the flexibility of the Forge OS, a robust robotics operating system, with the reliability and performance of a KEBA PLC module, making it an ideal choice for developers looking to create scalable, efficient robotic applications.

Designed for integration in distributed control systems (DCS), this system supports a wide range of industrial applications, from manufacturing automation to material handling and robotic systems. It offers real-time control and advanced capabilities for industrial robots, with a focus on simplifying robotic integration and improving overall system performance.

The KEBA controller within the kit provides a powerful and reliable platform for controlling robotic systems, while the Forge OS offers a flexible development environment that supports various programming interfaces, protocols, and hardware components. This makes it an ideal solution for automation experts and developers looking to quickly prototype and deploy robotics solutions in various industries.

Key Features:

- Forge OS Integration: The Forge OS allows seamless interaction with the robotic system and is designed to support multi-robot coordination and advanced automation tasks.

- KEBA PLC Controller: Combines the high reliability and processing power of the KEBA PLC for real-time industrial control, ideal for process automation and robotics.

- Developer Kit: This kit is designed for developers, offering an easy-to-use platform for creating custom robotic applications and integration with industrial automation systems.

- Modular System: Offers flexibility and scalability for building complex automation systems with multiple robot arms or devices.

- Comprehensive Communication Protocol Support: Supports a wide range of industrial communication protocols, ensuring seamless integration with other industrial equipment and control systems.

- Robust Build Quality: Designed to withstand demanding industrial environments, ensuring long-term performance and reliability.

Product Parameters:

-

Model Name:

KEBA Ready Robotics Forge OS Developer Kit Block 1 with KEBA Controller -

Controller Type:

Distributed Control System (DCS) PLC Module with KEBA controller. -

Operating System:

Forge OS (Real-Time Robotics Operating System). -

Power Supply:

Typically operates with a 24V DC power supply, suitable for industrial environments. -

Input/Output Expansion:

Supports modular I/O expansion for connecting various industrial devices and sensors. -

Robotic Integration:

Compatible with industrial robots and robotic arms, supporting integration with a wide range of motion control and actuator systems. -

Communication Protocols:

- Ethernet/IP

- Modbus TCP

- EtherCAT

- Profinet (depending on configuration)

-

Temperature Range:

Typically operates within the range of 0°C to 50°C, ensuring functionality in industrial conditions. -

Application Environment:

Designed for manufacturing, robotic systems, material handling, assembly lines, and automated processes.

Product Specifications:

-

Controller and Processing:

- KEBA PLC Controller with real-time processing capability for reliable control of robotic systems and automation tasks.

- Advanced multi-threaded processing for handling multiple robots or devices simultaneously.

-

Forge OS Features:

- The Forge OS offers an intuitive platform for rapid development of robotic applications, providing easy integration with robot arms, grippers, and other end-effectors.

- Built to support advanced motion control, path planning, and machine vision.

- ROS (Robot Operating System) integration for compatibility with a wide range of third-party libraries and tools.

-

Connectivity and Communication:

- Supports Ethernet for network communication, allowing the system to integrate with other control systems, HMIs (Human-Machine Interfaces), and SCADA systems.

- Built-in Ethernet/IP and Modbus TCP support for easy communication with other industrial devices and machinery.

- Real-time communication capabilities for precise control of industrial robots.

-

Modular and Scalable Design:

- The DCS PLC module can be expanded with additional I/O modules to accommodate complex automation tasks and control large numbers of devices.

- Ideal for scalable solutions involving multi-robot systems, automated production lines, and advanced material handling systems.

-

Robust Industrial Performance:

- Designed to operate in harsh industrial environments with high durability and long-term reliability.

- The controller is engineered to withstand extreme temperatures, vibration, and electromagnetic interference (EMI) typically found in manufacturing and robotic systems.

-

Safety and Compliance:

- The system integrates safety features like safe torque off (STO), emergency stop (E-Stop), and safety-rated outputs.

- Compliance with international safety standards, such as ISO 13849, IEC 61508, and EN 60204.

-

User Interface:

- The kit provides a user-friendly interface for easy configuration, monitoring, and troubleshooting.

- Developers can program and configure the system using standard tools, including support for C++, Python, and ROS.

-

I/O Expansion Capabilities:

- The system supports the addition of multiple I/O points, including analog and digital inputs/outputs, and specialty modules for advanced applications like motion control or vision systems.

- The flexible I/O configuration allows for the integration of sensors, actuators, camera systems, and more.

-

Diagnostics and Maintenance:

- Built-in diagnostic tools to monitor system performance, detect faults, and provide insights into the health of both the controller and robotic systems.

- Continuous monitoring of system parameters to ensure smooth and uninterrupted operation.

Applications:

The KEBA Ready Robotics Forge OS Developer Kit Block 1 with KEBA Controller is ideal for a variety of advanced industrial applications:

- Robotic Automation: Integration with robotic arms and end-effectors for tasks like pick and place, assembly, welding, and packaging.

- Manufacturing and Production: Control and monitor automated production lines, CNC machining, and assembly stations.

- Material Handling: Manage automated conveyor systems, robotic palletizers, and material transport in warehouses or factories.

- Laboratory Automation: Suitable for research and development or automated testing systems.

- Precision Assembly: Integration into precision manufacturing where accuracy and real-time control are crucial.

Conclusion:

The KEBA Ready Robotics Forge OS Developer Kit Block 1 with KEBA Controller provides a powerful and flexible platform for industrial robotic automation, combining KEBA’s reliable PLC control with the Forge OS for seamless robotic integration. It’s the perfect solution for developers looking to create efficient, scalable, and reliable robotic systems for a variety of industrial applications.

Let me know if you need further details or specifications!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922