الوصف

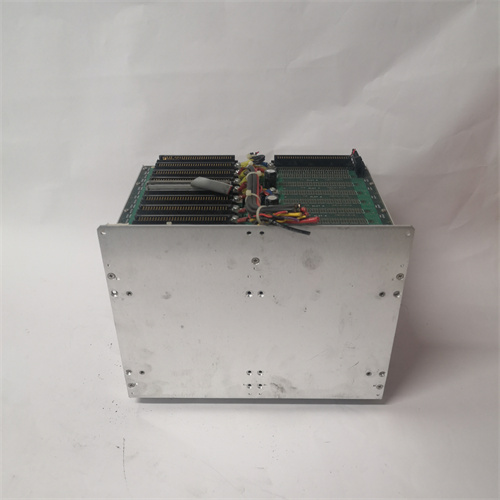

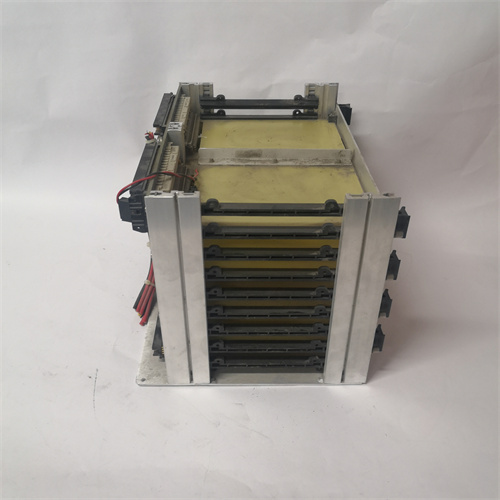

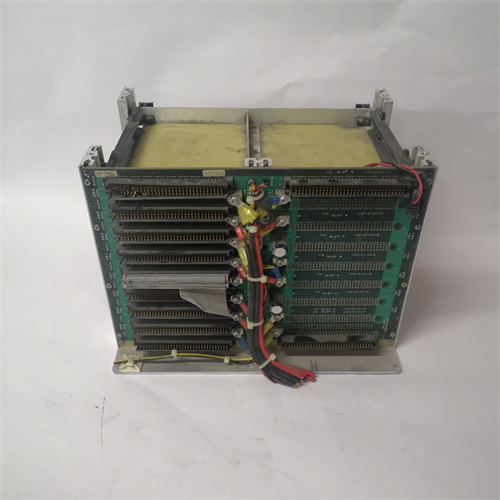

MOTOROLA AET-3047 DCS/PLC Module

Product Name:

MOTOROLA AET-3047 – Distributed Control System (DCS) / Programmable Logic Controller (PLC) Module

Product Description:

The MOTOROLA AET-3047 module is a component designed for use in Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC). It is typically used in industrial automation and control systems where high-performance, reliable processing is required. The AET-3047 is engineered to support advanced communication protocols, real-time control, and monitoring, enabling it to be integrated into complex industrial systems, particularly in sectors such as manufacturing, power generation, and oil & gas.

This module plays a key role in bridging the communication and processing needs between field devices (e.g., sensors, actuators) and the central control system, ensuring smooth operation and efficient monitoring of various industrial processes.

Product Parameters & Specifications:

-

Model Name: MOTOROLA AET-3047

-

Module Type: I/O Module for DCS/PLC

-

Compatibility: Designed for integration into Motorola-based DCS systems and other PLC-based systems.

-

Functionality:

- Acts as a communication interface between the control system and field devices.

- Supports real-time data acquisition, processing, and control of industrial automation processes.

- Provides input and output interfaces for digital, analog, and sometimes specialized signals.

-

Inputs/Outputs:

- Digital Inputs/Outputs: Typically used for on/off signals from sensors or relays.

- Analog Inputs/Outputs: Handles continuous signals, such as temperature, pressure, flow, etc.

- Specialized I/O: Depending on the system configuration, may support other specialized signal types (e.g., temperature sensors, current loops).

-

Communication Interface:

- Ethernet / TCP/IP: The AET-3047 supports high-speed Ethernet communication for seamless data transfer between field devices and the DCS/PLC.

- RS-232/RS-485 Communication: Depending on configuration, it might support serial communication for older or more specialized field devices.

-

Power Supply:

- Typically powered by 24 VDC, common in industrial control systems.

-

Processing Capabilities:

- Real-Time Processing: Handles high-speed processing and execution of control logic in real-time.

- Embedded Control Logic: May support programmable logic for direct field device control or signal processing.

-

Network Integration:

- Industrial Ethernet: Supports fast, reliable data exchange across the control network with Ethernet-based communication.

- Modbus/TCP and other common protocols for industrial automation systems are supported.

-

Environmental Operating Conditions:

- Operating Temperature Range: Typically 0°C to 60°C (varies by installation and environment).

- Storage Temperature Range: -20°C to 70°C (varies).

- Relative Humidity: 5% to 95% (non-condensing).

-

Protection Class: Generally, IP20 (indoor use, requires an enclosure).

-

Dimensions: Varies depending on the specific design of the module but may typically be around:

- Height: 150–200 mm

- Width: 100–150 mm

- Depth: 25–50 mm

-

Weight: Approx. 0.5–1.0 kg (depending on module configuration).

-

Mounting Type: Typically rack-mounted, compatible with a wide range of Motorola DCS/PLC racks.

-

Certifications: Likely to include industrial certifications such as UL, CE, and CSA, depending on the specific module and its application.

Additional Features:

-

Real-Time Diagnostics:

- Integrated diagnostic features that monitor the health and performance of both the module and connected field devices.

- Built-in LED indicators to provide visual feedback on module status, power, and communication activity.

-

Redundancy Support:

- Some configurations may support network redundancy, ensuring continued operation in case of network failure or communication disruption.

-

Modular Design:

- Modular installation allows for easy expansion or reconfiguration of the control system by adding or removing I/O modules as needed.

-

Integration with Legacy Systems:

- Can often be integrated with older Motorola systems or systems from other manufacturers, making it ideal for plant upgrades or mixed-technology environments.

-

Field Device Compatibility:

- Supports a wide range of industrial sensors, actuators, and control devices, making it suitable for applications in power plants, oil refineries, water treatment plants, and more.

-

Flexible I/O Configuration:

- The module allows for flexible configuration of inputs and outputs to meet the specific needs of the control system.

Applications:

- Power Generation:

- Used in power plant control systems for turbine monitoring, generator control, and other critical processes.

- Oil & Gas:

- Ideal for control and automation in refineries, offshore platforms, and pipeline monitoring.

- Manufacturing & Industrial Automation:

- Plays a central role in manufacturing control systems, including robotics, conveyor systems, and process control.

- Water Treatment & Utilities:

- Controls and monitors water treatment plants, sewage processing, and utility infrastructure systems.

Advantages:

- High-Speed Data Transfer: Ethernet-based communication ensures low-latency and high-bandwidth for real-time data processing.

- Robust Diagnostics and Monitoring: Diagnostic capabilities enhance system uptime by enabling proactive maintenance and fault detection.

- Flexibility: Modular and customizable I/O configurations provide high adaptability to various industrial applications.

- Reliability: Built to perform in harsh industrial environments, ensuring minimal downtime in mission-critical applications.

- Scalable: Easily scalable, enabling expansion or modification of the system as process requirements change.

The MOTOROLA AET-3047 module is a versatile, high-performance solution for industrial automation, control, and monitoring within DCS/PLC systems. Its robust design, modularity, and support for real-time processing make it an ideal choice for a wide range of applications, from power plants to manufacturing systems. With strong diagnostic capabilities, flexible communication protocols, and ease of integration, it is suited for industries requiring reliable and precise control over complex processes.

5461-772 PLC

5461-773 PLC

5461-774 PLC

5461-290 PLC

5461-292 PLC

5461-331 DCS

5461-639 DCS

5461-622+b2 PLC

5461-640 PLC

5461-641 PLC

5461-642 PLC

5461-780 PLC

5461-781 PLC

5462-518 PLC

5462-519 PLC

5461-880 PLC

5461-892 PLC

5461-798 DCS

5461-944 PLC

5462-520 PLC

5462-521 PLC

5462-522 dcs

5462-523 DCS

5461-975 PLC

5461-775 DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922