الوصف

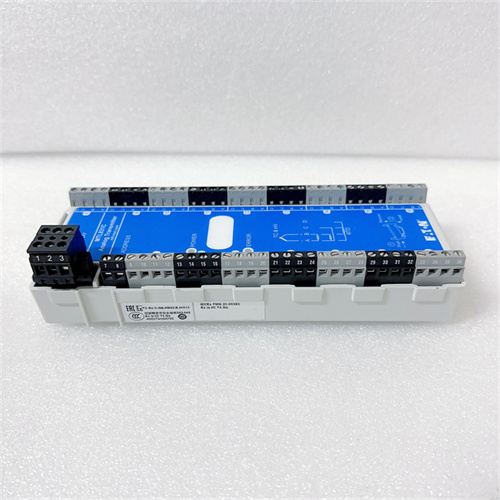

MTL MTL831B DCS/PLC Module

Product Name:

MTL MTL831B DCS/PLC Module

Product Description:

The MTL MTL831B is a high-performance Distributed Control System (DCS) / Programmable Logic Controller (PLC) module designed to provide robust control and monitoring capabilities for industrial automation and safety critical applications. Manufactured by MTL Instruments, part of the Eaton family of companies, the MTL831B is widely used in industries such as chemical, oil and gas, pharmaceuticals, utilities, and water treatment.

The MTL831B module offers flexible and reliable solutions for process control, data acquisition, and safety instrumented systems (SIS). It integrates seamlessly with other industrial systems and supports multiple communication protocols, allowing for smooth integration into existing control infrastructure. This module is ideal for both critical process applications and hazardous environments, offering a high degree of safety, reliability, and efficiency in operations.

Key Features:

-

Advanced Safety:

- Designed for safety-critical applications, ensuring high levels of safety and reliability in systems that require continuous operation.

-

Modular Design:

- The MTL831B has a modular architecture, allowing for easy expansion and flexible I/O configurations, making it adaptable to diverse industrial processes.

-

Redundancy and Reliability:

- Features redundant communication and power supply options for increased availability and fault tolerance, ensuring continuous operation during failures.

-

Communication Flexibility:

- Supports a range of industrial communication protocols such as Modbus, Profibus, and HART, enabling seamless integration with a wide array of control systems.

-

Real-Time Control:

- Capable of handling real-time control tasks and complex decision-making processes, ensuring fast response times to process changes and disturbances.

-

Process Control & Automation:

- Ideal for automating processes such as temperature, pressure, flow, and level control in various industrial environments.

-

Hazardous Area Compliance:

- Certified for use in hazardous areas with ATEX and IECEx certifications, making it suitable for explosive or flammable environments.

-

Scalability:

- Easily scalable to meet changing operational demands, with a wide range of I/O modules and expansion options available.

-

Real-Time Diagnostics:

- Provides integrated diagnostic tools for system health monitoring and fault detection, enabling proactive maintenance and minimizing downtime.

Product Parameters and Specifications:

General Specifications:

- Product Name: MTL MTL831B

- Type: DCS/PLC Module

- Manufacturer: MTL Instruments (Eaton)

- Function: Process Control, Automation, Safety Instrumented Systems (SIS)

Electrical Specifications:

- Input Voltage:

- Typically 24V DC (nominal) with operational range between 18V DC to 30V DC.

- Power Consumption:

- Generally ranges between 5W to 20W, depending on the configuration and connected I/O modules.

- Operating Temperature:

- -20°C to +60°C (-4°F to 140°F) for standard operation.

- Storage Temperature:

- -40°C to +85°C (-40°F to 185°F).

- Humidity:

- 5% to 95% non-condensing.

I/O Configuration:

- Digital I/O:

- Supports discrete inputs and outputs, suitable for controlling devices such as switches, relays, and alarms.

- Analog I/O:

- Provides 4-20mA or 0-10V analog inputs and outputs for process measurement and control.

- Relay Outputs:

- Includes relay outputs for activating external equipment like solenoids or control valves.

Communication and Networking:

- Modbus RTU/TCP:

- Fully supports Modbus protocol for communication with other industrial equipment and control systems.

- Profibus:

- Integrates seamlessly with Profibus networks, allowing for efficient data exchange between field devices and control systems.

- HART:

- Compatible with HART protocol for smart device integration and real-time diagnostics from field instruments.

- Redundant Communication:

- Offers redundant communication paths to ensure network reliability and fault tolerance in critical applications.

Safety and Compliance:

- Hazardous Area Certification:

- ATEX and IECEx certified for use in hazardous areas, ensuring compliance with explosion protection standards.

- SIL Certification:

- Suitable for use in Safety Instrumented Systems (SIS) with certification for SIL 2 or SIL 3 applications, meeting safety integrity standards.

- EMC Compliance:

- Complies with EMC (Electromagnetic Compatibility) requirements to ensure reliable operation in electrically noisy environments.

- Industry Standards:

- Meets international safety standards such as IEC 61508, IEC 61511, and ISO 13849.

Software and Programming:

- Programming Languages:

- Supports standard programming languages, including Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST) for flexible control strategies.

- Configuration Tools:

- Compatible with MTL configuration tools for easy setup and parameterization of the system.

- Integration with DCS Systems:

- Easily integrates with larger DCS platforms for comprehensive process control and automation.

Maintenance and Diagnostics:

- Integrated Diagnostics:

- Includes comprehensive diagnostic features such as self-testing, health monitoring, and error logging to facilitate troubleshooting.

- Event Logging:

- Provides a built-in event log for recording critical system events and alarms to help operators analyze faults and take preventive measures.

- Predictive Maintenance:

- Supports predictive maintenance strategies by analyzing diagnostic data and providing early warning of potential system failures.

Applications:

-

Oil & Gas:

- Used for wellhead control, pipeline monitoring, and refinery automation in the oil and gas industry, where process reliability and safety are critical.

-

Chemical Processing:

- Controls chemical reactions, monitoring pressure, temperature, and flow in chemical plants to maintain safe and optimal operating conditions.

-

Pharmaceuticals:

- In pharmaceutical manufacturing, the module ensures precise control of variables like temperature, pH, and flow, ensuring product quality and regulatory compliance.

-

Water Treatment:

- Ideal for managing filtration systems, chemical dosing, and water quality monitoring in water treatment and wastewater plants.

-

Utilities and Power:

- Used in power generation and utility management to ensure efficient operation of power plants and distribution systems.

Conclusion:

The MTL MTL831B DCS/PLC Module is a versatile and reliable solution for industrial automation and safety control in critical applications. With its modular design, redundant communication, and support for multiple protocols like Modbus, Profibus, and HART, it provides robust solutions for process control in hazardous environments. Certified for use in SIL and explosive atmospheres, the MTL831B ensures high levels of safety, reliability, and efficiency in industries such as oil and gas, chemical, and utilities. Its flexible I/O configuration, real-time diagnostics, and easy integration with existing control systems make it an ideal choice for demanding industrial environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922