الوصف

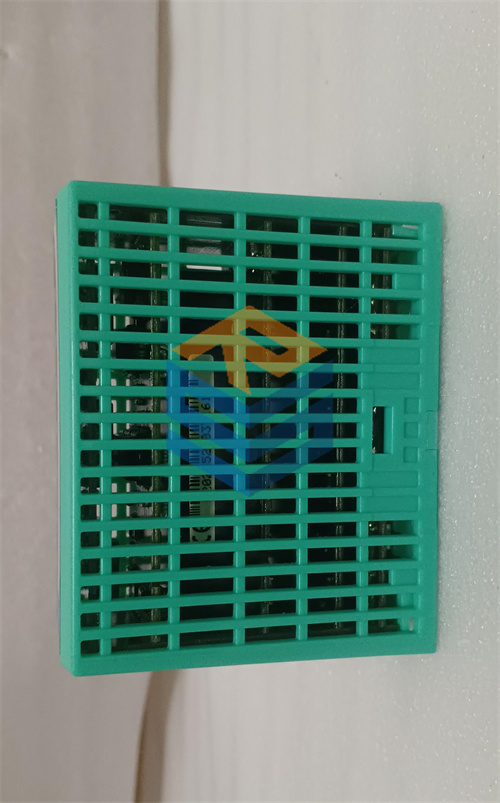

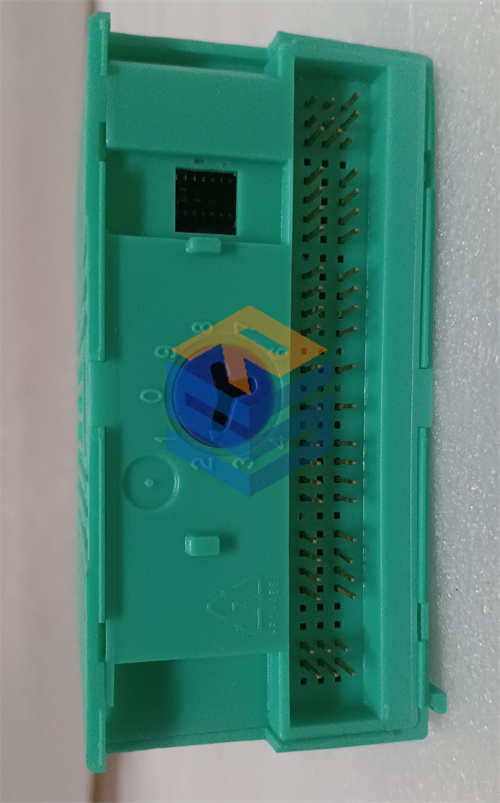

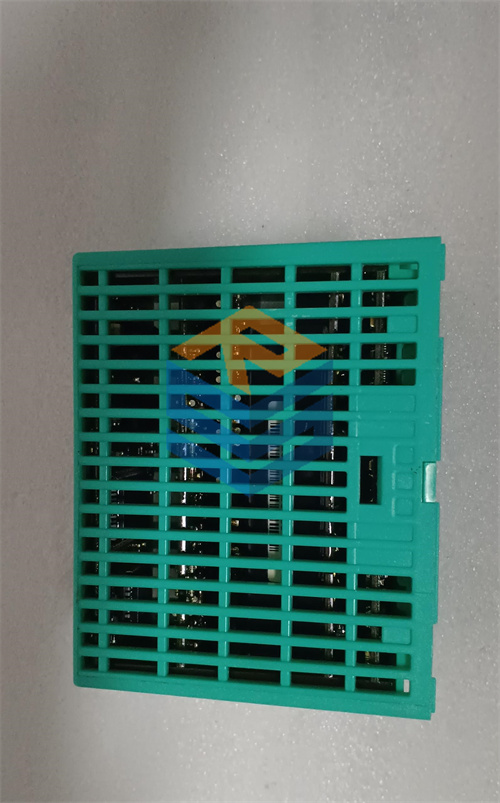

The PEPPERL+FUCHS RS-TB-EX. SP is an explosion-proof terminal board for a remote I/O system, specifically designed to safely interface with field devices located in hazardous (potentially explosive) areas. This product is a critical component for ensuring the safety and reliability of control systems in industries like oil and gas, chemical processing, and pharmaceuticals.

Technical Breakdown 🛠️

This part’s name reveals its key functions and features:

- RS (Remote System): The board is part of a modular remote I/O system, allowing you to connect a wide range of field instruments (like sensors and transmitters) and actuators over a long distance back to the main control system (DCS or PLC) in a safe area. This modularity simplifies installation and reduces cabling costs.

- TB (Terminal Board): This board serves as the physical interface for all field wiring. It has screw terminals that provide a robust and secure connection point for a device’s wires, streamlining the wiring process and providing a clear, organized layout.

- EX (Explosion Protection): This is the most crucial aspect. The board is designed for use in hazardous locations, utilizing a type of protection known as intrinsic safety. This technology limits the electrical and thermal energy of a circuit to a level below what’s required to ignite a flammable gas or dust mixture. By incorporating intrinsic safety barriers, the board ensures that no spark or heat source can be generated in the hazardous area, even under fault conditions.

- SP (Special/Spare Part): The “SP” designation indicates a specific variant of the product, possibly a spare part or a version with unique terminals or a different physical configuration.

In essence, the RS-TB-EX. SP acts as a vital safety barrier, allowing you to run signals from dangerous zones to a control room with complete peace of mind, knowing that the system’s design prevents explosions.

Key Specifications 📊

Typical Applications 🏭

- Oil & Gas: Controlling and monitoring equipment on drilling platforms, refineries, and pipelines.

- Chemical Industry: Managing processes in plants where flammable vapors or liquids are present.

- Pharmaceuticals: Ensuring safety during the production of drugs in environments with flammable solvents or powders.

- Wastewater Treatment: Automating processes in areas where methane gas may accumulate.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922