الوصف

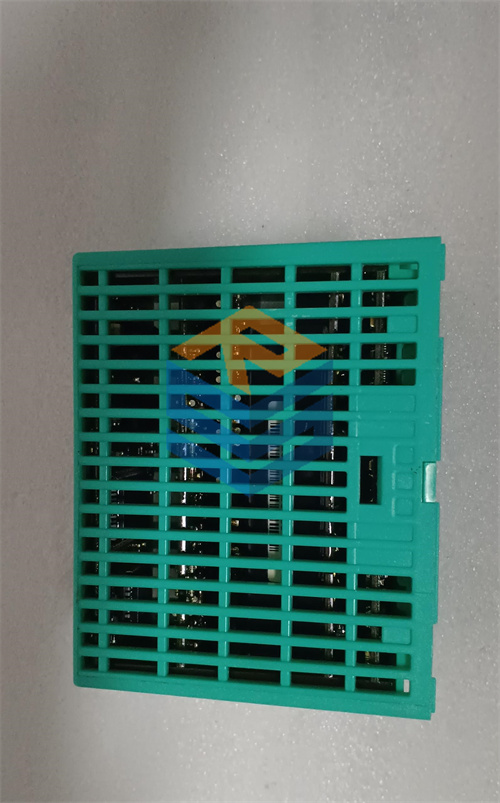

The Pepperl+Fuchs RSD-GW2-Ex2.DPE is an intrinsically safe PROFIBUS DP-V1 gateway module used in industrial automation. Its primary function is to serve as the critical communication link between a network of remote I/O modules in a hazardous area and a central control system (like a PLC or DCS) located in a safe area.

Technical Breakdown 🛠️

The model number for this module provides a clear breakdown of its capabilities:

- RSD (Remote System Division): This signifies the module is part of Pepperl+Fuchs’s modular remote I/O family. These systems allow you to install I/O modules and their gateway directly in hazardous areas, providing a safe link back to the main controller in a safe location.

- GW2 (Gateway): This is the core function of the module. It acts as a bridge, translating data between the proprietary internal bus of the remote I/O system and the external, plant-wide PROFIBUS network. It is the communication hub for the entire I/O station. The “2” indicates it’s a specific revision, which may affect compatibility with certain I/O modules or firmware versions compared to its predecessor or the newer GW3 model.

- Ex2 (Explosion Protection): This is the module’s most critical feature. The “Ex” designation confirms it is certified for use in hazardous areas (specifically Zone 1 or Zone 2, and Zone 22 for dust). The module achieves this through intrinsic safety, a protection technique that limits the electrical and thermal energy of the circuit to a level below what’s required to ignite a flammable mixture of gas, vapor, or dust. This allows for safe operation and even hot-swapping (replacing the module while the system is live) in hazardous environments.

- DPE (PROFIBUS DP-V1): This indicates the module supports the PROFIBUS DP-V1 communication protocol. PROFIBUS is a leading fieldbus for fast, reliable communication between controllers and distributed I/O. The “V1” variant supports advanced functions like acyclic data exchange, alarm handling, and HART communication, making it a highly versatile and powerful link for complex process automation.

Typical Applications 🏭

- Chemical Industry: For connecting instruments in tanks and reactors to the control system.

- Oil & Gas: Used on offshore platforms or in refineries to link field devices in hazardous areas to the central control room.

- Pharmaceuticals: In manufacturing processes that involve flammable solvents or powders.

- Wastewater Treatment: Automating processes in areas where methane gas may accumulate.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922