الوصف

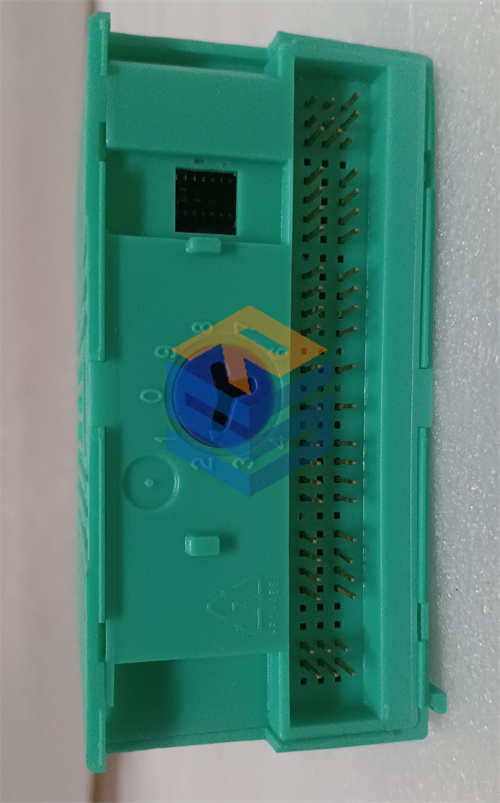

The Pepperl+Fuchs RSD2-ISO-Ex is an intrinsically safe backplane bus isolator module. Its primary function is to provide galvanic isolation for the backplane bus within a remote I/O system, enabling the safe and simultaneous connection of both intrinsically safe and non-intrinsically safe signals to the same system.

Key Features and Functionality 🛠️

The model number for this module breaks down to reveal its specific capabilities:

- RSD2 (Remote System Digital): This indicates the module is part of Pepperl+Fuchs’s modular remote I/O family. These systems are used to connect a wide range of sensors and actuators in hazardous areas (e.g., Zone 1 or Zone 2) to a central control system in a safe area, simplifying wiring and reducing costs.

- ISO (Isolator): This is the core function of the module. It provides galvanic isolation, which means it electrically separates different parts of a circuit. In this case, it isolates the intrinsically safe portion of the system’s internal bus from the non-intrinsically safe portion. This is critical for preventing ground loops and ensuring that electrical faults or surges on one side of the system cannot affect the other, which is essential for both signal integrity and safety.

- Ex (Explosion Protection): This is the module’s most critical safety feature. The “Ex” designation confirms it is certified for use in hazardous areas. It achieves this through intrinsic safety, a protection technique that limits the electrical and thermal energy of the circuit to a level too low to ignite a flammable mixture of gas, vapor, or dust. This allows for safe operation and even live maintenance in hazardous environments without the need for heavy, explosion-proof enclosures.

In a practical application, this module is typically used in a scenario where a remote I/O system is installed in a safe area but must connect to both safe-area devices (e.g., a non-Ex gateway) and hazardous-area devices. The RSD2-ISO-Ex acts as the crucial safety barrier, converting non-intrinsically safe bus signals into intrinsically safe signals to protect the hazardous area.

Typical Applications 🏭

- Process Automation: Providing a secure interface in refineries, chemical plants, and pharmaceutical facilities where both hazardous and safe area signals need to be integrated into a single remote I/O system.

- System Integration: Used by system integrators to build custom control panels that incorporate a mix of standard industrial components and intrinsically safe field instruments.

- Modernization Projects: A key component for upgrading legacy control systems, allowing for the use of new fieldbus-based remote I/O while maintaining stringent safety standards.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922