الوصف

Product Name

PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE

Product Description

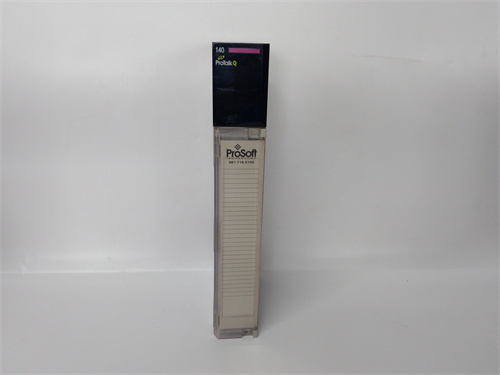

The PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE is a state-of-the-art PLC automation device widely recognized for its reliability and performance in various industrial applications. Designed by ProSoft Technology, this device enables seamless communication and data transfer in a multi-protocol environment. The PLX32-EIP-SIE provides exceptional support for Ethernet/IP, enhancing connectivity between different devices in an automated setup.

The PROSOFT+PTQ-PDPMV1 is engineered to simplify integration into existing systems while offering robust features that ensure optimal performance. It supports advanced diagnostics, which are critical for troubleshooting and maintenance in complex automation systems. By utilizing the PLX32-EIP-SIE, users can experience improved system efficiency and reduced downtime.

Product Parameters

- PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE

- Protocol Support: Ethernet/IP, Modbus TCP/IP

- Processing Speed: Up to 1ms for data transmission

- Number of Ports: 2 Ethernet ports for redundancy

- Operating Temperature: -20°C to 70°C

- Power Supply: 24V DC input

- Dimensions: Compact design suitable for tight spaces

Advantages and Features

The PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE boasts several advantages:

- Versatile Protocol Support: Enables integration with different network protocols, allowing for flexible configuration in various automation environments.

- High-Speed Communication: Ensures rapid data transfer and minimal latency, crucial for time-sensitive applications.

- Redundant Ports: Provides enhanced reliability by allowing network redundancy, reducing the risk of data loss.

- Compact Design: Fits into limited spaces, making it suitable for diverse installation scenarios.

- User-Friendly Interface: Simplifies setup and configuration, minimizing the overall deployment time.

Application Fields and Case Studies

The PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE is widely used in several industries, including:

- Manufacturing Automation: Facilitating communication between PLCs, HMIs, and other devices in a production line.

- Oil and Gas: Ensuring seamless data exchange in complex monitoring systems.

- Water Treatment: Connecting various components in SCADA systems for real-time monitoring and control.

A notable case study involved a manufacturing company that implemented the PLX32-EIP-SIE to streamline its production process. By integrating this device, the facility achieved a 30% reduction in downtime and improved overall efficiency.

Competitive Comparison

When comparing the PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE with other similar devices in the market, key differentiators include:

- Superior Data Handling: Competing products may have limitations in protocol support, while the PLX32-EIP-SIE excels in multi-protocol capabilities.

- Robust Diagnostics: While some competitors offer basic diagnostic tools, the PROSOFT+PTQ-PDPMV1 provides advanced diagnostics that aid in efficient troubleshooting.

- Reliability: The redundancy features of the PLX32-EIP-SIE stand out, ensuring continuous operation without interruptions compared to rivals.

Selection Recommendations

When selecting a PLC automation device, consider using the PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE for projects requiring high-speed data transfer and reliable connectivity across diverse networks. Evaluate your specific application needs, such as the required communication protocols and environmental conditions. This will ensure you choose the most suitable device for your automation requirements.

Precautions

During installation and operation of the PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE, keep in mind the following:

- Ensure proper power supply ratings to prevent damage to the unit.

- Maintain proper temperature ranges to ensure optimal device performance.

- Regularly update the firmware to utilize the latest features and improvements.

We are your trusted partner, providing sales and technical support for the PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE and other automation spare parts. Enjoy special discount prices by contacting us, and we will be dedicated to serving you.

PROSOFT+PTQ-PDPMV1 PLX32-EIP-SIE

| EMERSON KJ2201X1-JA1 |

| EMERSON KJ2221X1-BA1 |

| EMERSON KJ2221X1-EA1 |

| EMERSON KJ2222X1-BA1 DCSPLC |

| KJ2231X1-BA1 EMERSON |

| EMERSON KJ2231X1-BB1 |

| EMERSON KJ2231X1-BC1 |

| EMERSON KJ2231X1-EA1 |

| EMERSON KJ2231X1-EB1 |

| EMERSON KJ2231X1-EC1 |

| EMERSON KJ2231X1-ED1 PLC |

| KJ2231X1-EE1 EMERSON |

| EMERSON KJ3001X1-BA1 PLC |

| EMERSON KJ3001X1-BB1 DCS |

| EMERSON KJ3001X1-BC1 DCS |

| EMERSON KJ3001X1-BD1 PLC |

| EMERSON KJ3001X1-BE1 |

| KJ3001X1-BH1 EMERSON |

| KJ3001X1-BJ1 EMERSON DCSPLC |

| EMERSON KJ3001X1-BK1 |

| EMERSON KJ3001X1-CA1 |

| EMERSON KJ3001X1-CB1 DCSPLC |

| KJ3002X1-BA1 EMERSON |

| EMERSON KJ3002X1-BB1 |

| EMERSON KJ3002X1-BC1 |

| EMERSON KJ3002X1-BD1 |

| EMERSON KJ3002X1-BE1 |

| EMERSON KJ3002X1-BF1 |

| EMERSON KJ3002X1-BG2 DCSPLC |

| EMERSON KJ3003X1-BA1 |

| EMERSON KJ3003X1-EA1 |

| EMERSON KJ3004X1-BA1 |

| EMERSON KJ3004X1-EA1 |

| EMERSON KJ3005X1-BA1 |

| EMERSON KJ3006X1-BA1 |

| EMERSON KJ3007X1-BA1 |

| EMERSON KJ3007X1-EA1 DCSPLC |

| EMERSON KJ3008X1-BA1 |

| KJ3009X1-BA1 EMERSON |

| EMERSON KJ3102X1-BA1 |

| EMERSON KJ3102X1-BB2 () |

| EMERSON KJ3201X1-BA1 PLC |

| EMERSON KJ3201X1-BJ1 |

| KJ3201X1-EA1 EMERSON |

| EMERSON KJ3202X1-BA1 |

| EMERSON KJ3203X1-BA1 |

| EMERSON KJ3204X1-BA1 |

| EMERSON KJ3206X1-BA1 |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922