الوصف

Product Name

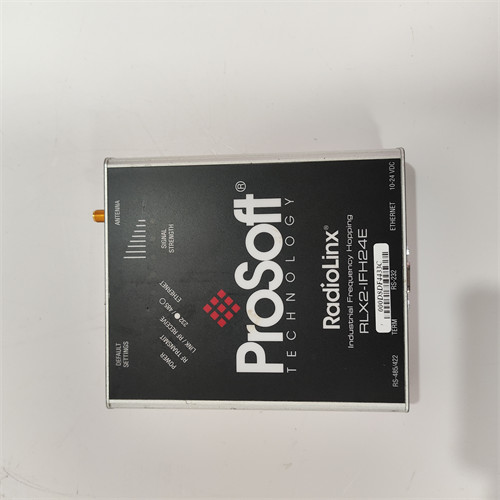

Prosoft RLX2-IFH24E

Product Description

The Prosoft RLX2-IFH24E is a highly reliable and efficient communication device designed for use in industrial automation systems. This model stands out for its ability to facilitate seamless data transfer and integration between various PLCs, as well as other automation equipment. With the Prosoft RLX2-IFH24E, users can achieve enhanced connectivity and real-time monitoring capabilities, which are essential for modern manufacturing processes.

The Prosoft RLX2-IFH24E features robust communication protocols that enable it to support various network configurations, making it an ideal choice for diverse applications. Its versatility ensures that it can be effectively implemented in multiple industrial environments, delivering consistent performance and operational efficiency.

Product Parameters

- Model: Prosoft RLX2-IFH24E

- Power Supply: 24V DC

- Communication Ports: 2 Ethernet ports, 1 Serial port

- Protocol Support: Modbus TCP/IP, EtherNet/IP, and more

- Operating Temperature: -20 to 70 degrees Celsius

- Mounting Type: DIN Rail

- LED Indicators: Status, Power, and Communication

Advantages and Features

The Prosoft RLX2-IFH24E offers several advantages and features that set it apart from competitors:

- High Data Throughput: Capable of handling large volumes of data, ensuring minimal latency.

- Easy Integration: Designed to work smoothly with a variety of PLCs and automation tools, reducing the time and effort required for setup.

- Flexible Configuration: Users can easily configure communication protocols to suit specific application needs.

- Durability: Built to withstand harsh industrial conditions, ensuring long-lasting performance.

- User-Friendly Interface: Its intuitive setup process allows for easy monitoring and management.

Application Fields and Case Studies

The Prosoft RLX2-IFH24E is widely applicable across multiple industries, including:

- Manufacturing: Streamlining operations by connecting various machinery and systems within the production line.

- Oil and Gas: Enabling safe and efficient data transport from remote sites to control centers.

- Water Treatment: Facilitating real-time monitoring of systems for improved resource management.

- Logistics: Enhancing inventory tracking and management through various PLC connections.

In one notable case, a manufacturing facility was able to increase production efficiency by 30% after integrating the Prosoft RLX2-IFH24E, resulting in significant cost savings and improved output.

Competitive Comparison

When evaluating the Prosoft RLX2-IFH24E, it’s useful to consider its key competitors:

- Siemens SCALANCE: While Siemens offers a robust communication product line, its solutions often come with a higher cost and complexity.

- Rockwell Automation Stratix: Provides excellent integration with Rockwell PLCs, but may lack the versatility of the Prosoft RLX2-IFH24E for non-Rockwell equipment.

- Moxa EDS Series: Known for good performance, yet may not provide the same level of protocol support as the Prosoft RLX2-IFH24E.

Overall, the Prosoft RLX2-IFH24E exhibits competitive pricing combined with superior flexibility and ease of use, making it an attractive option for automation professionals.

Selection Recommendations

When choosing the Prosoft RLX2-IFH24E, consider the following factors:

- Network Requirements: Evaluate the types of communication protocols your existing systems use to ensure compatibility.

- Environmental Conditions: Confirm that the operational temperature range meets the specific requirements of your industry.

- Integration Needs: Assess how many devices will need to be connected and the data throughput necessary for optimal performance.

Precautions

While utilizing the Prosoft RLX2-IFH24E, keep the following precautions in mind:

- Electrical Specifications: Ensure that the power supply matches the product requirements to prevent damage.

- Installation Location: Mount in a suitable environment to avoid exposure to extreme temperatures or moisture.

- Firmware Updates: Regularly check for firmware updates to maintain security and improve functionality.

We are your trusted partner, providing the Prosoft RLX2-IFH24E and other automation spare parts with sales and technical support. We offer special discounted prices. Please contact us, and we will be at your service.

Prosoft+RLX2-IFH24E

| TRICONEX 8112 |

| TRICONEX 8111 |

| TRICONEX 8110 PLC |

| TRICONEX 3625 PLC |

| 4000094-310 PLC |

| TRICONEX 4000093-310 PLC |

| TRICONEX 2553-87400056-380 PLC |

| TRICONEX 25537400056-310 PLC |

| TRICONEX 2652-97400058-390 PLC |

| TRICONEX T8111 |

| TRICONEX 8112 PLC |

| TRICONEX 2755 |

| TRICONEX 3604A PLC |

| TRICONEX 3502E PLC |

| TRICONEX 2652-310 PLC |

| TRICONEX 2755-020 PLC |

| TRICONEX 2651-100 PLC |

| TRICONEX 3624 PLC |

| TRICONEX 4609 PLC |

| TRIC0NEX 4409 plc |

| TRICONEX 4329 |

| TRICONEX 4119 PLC |

| TRICONE 4118 PLC |

| TRICONEX 4108 PLC |

| TRICONEX 7518-1 PLC |

| TRICONEX 4508 PLC |

| TRIC0NEX 4400 PLC |

| TRICONEX-4328 PLC |

| TRIC0NEX-8306A PLC |

| TRICONEX-4508 PLC |

| TRICONEX-4400 PLC |

| TRICONEX-8306A PLCI/O |

| TRIC0NEX-8305A |

| TRICONEX-8307A |

| TRICONEX-3005 PLC |

| TRICONEX-3004 PLC |

| TRICONEX-3008 PLC |

| TRICONEX-3006 PLC |

| TRICONEX-8312 PLC |

| TRICONEX-8311 LC |

| TRICONEX-8310 PLC |

| TRICONEX-8301A PLC |

| TRICONEX-8300A PLC |

| TRICONEX-8302A PLC |

| TRICONEX-8106 PLC |

| TRICONEX-8105 |

| TRICONEX-9001 |

| TRICONEX-9000 |

| TRICONEX-8102 |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922