الوصف

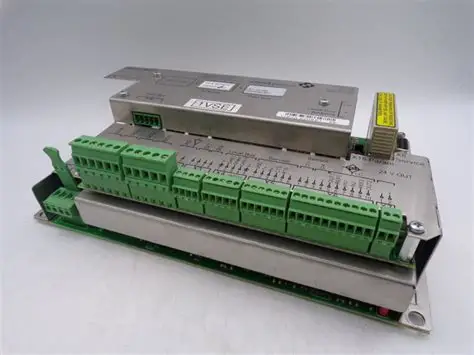

As an industrial automation expert, SCHENCK VEG20400 refers to a weighing terminal manufactured by Schenck Process. This is a specialized piece of industrial electronic equipment designed for precise weight measurement and process control in various industrial applications.

The VEG20400 is specifically identified as a “Front-of-panel-mounting unit” within the DISOMAT B plus weighing terminal series. This means it’s designed to be flush-mounted into a control panel or cabinet door, providing a user interface for weighing operations.

Schenck Process is a well-known global leader in industrial weighing, feeding, screening, and automation solutions, particularly for bulk material handling.

Key Features and Benefits:

- Comprehensive Weighing Terminal: It’s a fully equipped terminal offering advanced functionalities for various weighing applications.

- Clear Graphical Display: Features a graphics-capable, backlit LCD (240 x 64 pixels) for clear operator prompting and weight display (14mm digit height).

- Flexible Keyboard: Equipped with a membrane keyboard including 30 multi-function keys and 8 reserved for individual assignment, allowing for flexible operation.

- Industrial Fieldbus Connectivity: Supports various industrial fieldbus systems (though specific protocols might depend on optional interface modules like VSS20400 for serial, or VET020 for Ethernet, VPB020 for Profibus, VCB020 for DeviceNet). This enables seamless integration into larger automation systems.

- Integrated Legal-for-Trade Memory (Optional): Can be equipped with a legal-for-trade memory module (VMM20402) for storing weighing data, essential for compliance in commercial transactions.

- Modular Extensibility: Allows for modular expansion with additional I/O (4 binary inputs, 6 binary outputs), a second measuring channel (e.g., for multiple scales), or an analog output (VEA 20400 for 0/4-20mA).

- “Dongle” for Calibration Data: Crucially, scale characteristics and calibration data are stored in a load cell cable connector (dongle). This allows for the replacement of system components without recalibration or re-verification, significantly reducing downtime and repair costs.

- Preconfigured Applications: Comes preconfigured with six typical weighing applications, which can be easily called up.

- Robust Housing Options: The VEG20400 is specifically a “Front-of-panel-mounting unit” with IP54 front protection. Other housing variants in the DISOMAT B plus series (like desktop, stainless steel, field housing, 19″ rack, or local unit) are also available.

- High Resolution and Measuring Speed: Offers high resolution and a measuring rate of 132 measurements/second (66/second for two-channel variants), providing reserves for difficult weighing applications and fast filling processes.

Technical Specifications (based on DISOMAT B plus series documentation):

Typical Applications:

The SCHENCK VEG20400, as part of the DISOMAT B plus series, is ideally suited for a wide range of weighing applications in various industrial sectors:

- Scale Control: Managing and operating industrial scales, including platform scales, hopper scales, and tank scales.

- Data Processing: Acquiring, processing, and displaying weight data for inventory management, quality control, and production monitoring.

- Process Control: Integrating into automated processes for tasks like:

- Filling and Dosing: Precise control of material filling processes for powders, granules, or liquids.

- Batching Systems: Managing recipes and controlling multiple components for batch production.

- Blending Systems: Ensuring accurate proportions of ingredients.

- Communication with User Systems: Providing an interface for data exchange with higher-level systems such as SCADA, MES, ERP, or PLCs via fieldbus or serial communication.

- Hazardous Areas: Specific variants (like VKG 20400-E) are available for use in potentially explosive atmospheres (ATEX Zones 2/22/21).

Industries that commonly utilize such weighing terminals include:

- Food and Beverage: Ingredient weighing, recipe management, packaging.

- Chemical and Pharmaceutical: Batching, blending, precise dispensing.

- Mining and Aggregates: Monitoring material flow, truck weighing, inventory control.

- Cement: Raw material dosing, clinker weighing.

- Plastics: Granule weighing and blending.

- Logistics and Transportation: Truck scales, in-motion weighing.

Related Products and Solutions:

To form a complete weighing solution with the SCHENCK VEG20400, you would typically integrate it with:

- Load Cells: The actual sensors that measure the weight (Schenck Process manufactures a wide range of load cells).

- Load Cell Junction Boxes: For connecting multiple load cells to the weighing terminal.

- Optional Interface Modules:

- VSS20400: For serial interface expansion.

- VET020: Ethernet interface module for DISOBOX (an A/D converter unit that connects to the terminal).

- VPB020: Profibus interface module for DISOBOX.

- VCB020: DeviceNet interface module for DISOBOX.

- VEA 20400: Analog output module.

- VMM20402: Legal-for-trade memory module.

- External Keyboards: Such as VTT20410 for convenient data input.

- Secondary Displays: DTA models for displaying weight values remotely.

- Schenck Process Weighing Scales/Systems: The complete mechanical scale structure that the terminal integrates with.

- SCADA/HMI Software: For visualization, data logging, and supervisory control of the weighing process.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922