الوصف

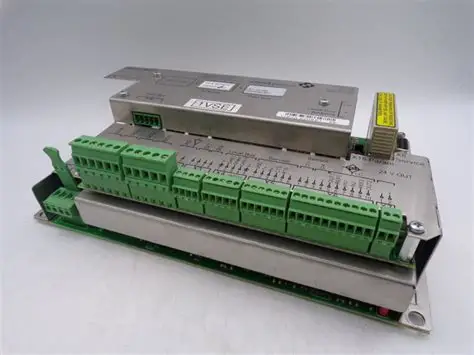

The SCHENCK VSE 20100 is a system unit designed for weighing and feeding systems, primarily as the central control electronic for the DISOCONT series. It performs all the measurement and control functions for these systems.

Key Features and Applications

- Core Function: The VSE 20100 is the brain of a DISOCONT system, handling all measuring and control tasks. It’s a key component in industrial processes that require precise measurement, feeding, and batching of bulk materials.

- Modular Design: It’s a highly modular system. It can be expanded with additional cards for things like fieldbus communication (e.g., PROFIBUS DP-V2, Ethernet/IP), analog inputs/outputs, or additional load cell interfaces, allowing it to be customized for a wide range of applications.

- Data Acquisition: The unit is known for its high-resolution data acquisition, ensuring accurate and reliable measurements from connected sensors.

- Onboard Memory: The VSE 20100 uses an exchangeable memory module to store system-specific settings and operating values, which is useful for configuration, calibration, and service. It can also save dynamic values in case of a power failure.

- User Interface: The unit is typically configured and serviced using a laptop or a connected operator panel with a dedicated software, such as “EasyServe.”

Common Applications:

The VSE 20100 is used in a variety of industries and applications, including:

- Belt weighers: For continuous weighing of bulk materials on conveyor belts.

- Loss-in-weight feeders: For accurately feeding a specific amount of material into a process.

- Solids flow meters and feeders: For measuring and controlling the flow of solid materials.

- Mass flow meters and feeders: For precise measurement and control of mass flow.

Technical Specifications

- Power Supply: The unit can be powered by either 24 VDC or a range from 110 V to 230 V AC.

- Inputs: It includes a load cell input, NAMUR inputs for speed measurement or other signals, and isolated digital inputs.

- Outputs: It has an isolated analog output for control signals.

- Installation: The VSE 20100 is designed to be mounted within a control cabinet housing (like a VFG or VEG housing) to ensure safety and protection.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922