الوصف

The item VIBRO-METER 200-595-045-114 CPUM refers to a specific Central Processing Unit Module (CPUM) within the Vibro-Meter VM600 series of machinery protection and condition monitoring systems.

The CPUM acts as the “brain” or “rack controller” for the entire VM600 rack, managing communication, configuration, and data exchange between the various monitoring and protection modules installed in the system.

SEO Optimized Headings:

- VIBRO-METER VM600 CPUM 200-595-045-114: Rack Controller & Communications Gateway.

- VM600 CPUM: Central Processing Unit for Machinery Protection Systems.

- VIBRO-METER 200-595-045-114: Networked VM600 System Control Module.

- VM600 CPU Module: Configuration and Data Aggregation for Industrial Assets.

- CPUM Rack Controller: Ethernet and Serial Connectivity for VM600.

- VIBRO-METER VM600 Series: Enabling Smart Monitoring and Predictive Maintenance.

Product Overview:

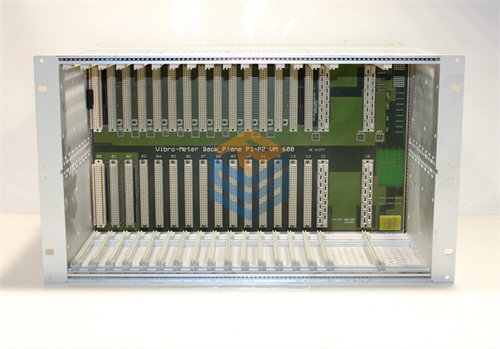

The VIBRO-METER VM600 CPUM (Central Processing Unit Module) is a modular CPU card designed to function as the rack controller and communications interface for a VM600 or VM600Mk2 rack-based machinery protection and/or condition monitoring system. It is a critical component that enables centralized control, configuration, and data exchange for all other modules within the rack.

The part number 200-595-045-114 identifies a specific variant of the CPUM module. While specific detailed differences between sub-variants can be subtle without direct factory documentation, this CPUM is part of the original CPUM generation (as opposed to the newer CPUMMk2 or CPUR2) and is designed to support various communication protocols.

Product Details:

The VIBRO-METER VM600 CPUM 200-595-045-114 is the central intelligence of a VM600 system. In a large industrial plant with numerous critical machines, having a centralized system to monitor their health is paramount. The CPUM facilitates this by collecting data from individual monitoring cards, managing alarms, and providing a gateway for this information to be accessed externally.

Imagine a power plant’s control room, where operators need a clear overview of all critical turbines and generators. The VM600 system provides this data, and the CPUM is the module responsible for gathering the processed information from all the individual protection and monitoring cards (like MPC4, XMV16, AMC8), aggregating it, and making it available to the operators’ displays or the plant’s Distributed Control System (DCS).

Here’s a breakdown of its key functions and attributes:

1. Rack Controller Functionality: * Central Control: The CPUM acts as the master controller for the entire VM600 rack. It oversees the operation of all installed monitoring and protection modules (e.g., MPC4, AMC8, XMV16). * Configuration Management (“One-Shot” Configuration): It enables efficient configuration of all protection and monitoring cards within the rack. Instead of configuring each card individually, engineers can connect to the CPUM (via Ethernet or RS-232) using VibroSight® or VM600 MPSx software and configure the entire rack’s modules in one go. * Alarm Management: It aggregates alarm and status information from all modules in the rack. It can trigger common alarms and handle alarm reset functions (e.g., via a front-panel button). * System Event Logging: The CPUM automatically logs VM600 system events and measurement events to non-volatile memory, providing a valuable historical record for troubleshooting and analysis. * Rack Security: Supports features to limit functionality access via Ethernet connections, enhancing the security of the machinery protection function.

2. Communication Gateway: * Internal Communication: Communicates with other VM600 modules in the rack via the VMEbus backplane to retrieve measurement data and status information. It also communicates with XMx16 (extended condition monitoring) modules via a dedicated Ethernet link if present. * External Communication: Provides various interfaces for communication with third-party systems such as: * Ethernet: Typically includes two Ethernet connections (primary and secondary) for redundant communication with a host PC running VibroSight software, or with plant-wide DCS/PLC systems using protocols like Modbus TCP/IP. * Serial: Supports multiple serial connections (RS-232, RS-422, RS-485) for communication using protocols like Modbus RTU. This allows for communication redundancy and multi-drop networks for multiple VM600 racks. * Data Sharing: Aggregates data (processed outputs, alarm status, raw data snapshots) from all modules in the rack and makes it available to external systems.

3. Modular Design and Hardware: * Card Pair: The CPUM typically functions as a card pair with an associated IOCN (Input/Output Card for Network) module. The CPUM is installed in the front of the rack, and the IOCN is installed directly behind it in the rear, providing the physical connectors for Ethernet and serial communication. * PC/104 Architecture: The CPUM card consists of a carrier board with PC/104 type slots, allowing for the installation of a CPU module and optionally an additional serial communications module for extended connectivity. * Front-Panel Display: Features an LCD display on the front panel to visualize monitored outputs, alarm limits, and the overall status of the CPUM and other cards in the rack. LEDs also indicate OK, Alert, and Danger statuses.

4. Power and Diagnostics: * Draws power (typically +5 VDC) from the VM600 rack’s power supply (RPS6U). * Includes diagnostic features (DIAG LED) to indicate its operational health and security status.

Regarding the part number 200-595-045-114: This part number specifies a particular configuration of the original CPUM. While a detailed public breakdown of all VM600 part number suffixes isn’t readily available, the “045” often indicates specific communication features or memory configurations. The CPUM (and its variants like this one) preceded the CPUMMk2 and CPUR2, which offer enhanced features such as mathematical processing of fieldbus data, improved security, and support for newer fieldbus protocols like PROFIBUS DP.

In essence, the VIBRO-METER VM600 CPUM 200-595-045-114 is the central orchestrator of a VM600 system, enabling its functionality as a comprehensive and networked machinery protection and condition monitoring solution.

Technical Specifications (Typical for VM600 CPUM 200-595-045-114):

The specifications provided are general for the CPUM module. Specific features and exact values for the 200-595-045-114 variant might have minor differences, particularly in relation to the specific PC/104 CPU module and optional communication modules fitted.

Applications and Industries:

The VIBRO-METER VM600 CPUM 200-595-045-114 is deployed in all applications where a centralized VM600 system is used for the protection and condition monitoring of critical rotating machinery. Its role as the rack controller and communication gateway makes it indispensable for integrating the VM600 system into a larger plant control and information infrastructure.

Consider a large offshore drilling rig. The rig operates multiple critical pumps, compressors, and power generation turbines in a confined and challenging environment. The VM600 system, with the CPUM at its heart, monitors these assets. The CPUM ensures that all vibration, temperature, and speed data from the various monitoring modules is collected, processed, and then transmitted via its Ethernet or serial connections to the rig’s main control room and possibly to onshore monitoring centers. This allows for real-time situational awareness, quick response to anomalies, and the ability to conduct remote diagnostics, which is crucial for safety and operational efficiency in such remote locations.

Key applications and industries include:

- Power Generation:

- Gas, Steam, and Hydro Turbines, Generators: Managing the overall health monitoring and protection system for prime movers and power generators.

- Balance-of-Plant (BOP) Equipment: Centralized control for monitoring large pumps, fans, and motors.

- Oil & Gas:

- Refineries, Pipelines, Offshore Platforms, LNG Plants: Controlling monitoring systems for critical turbomachinery such as compressors and gas turbines, ensuring their safe and continuous operation.

- Chemical and Petrochemical Industries:

- Managing the monitoring systems for high-speed rotating equipment in hazardous environments.

- Heavy Manufacturing:

- Steel mills, paper mills, cement plants: Providing central control for monitoring systems of large production machinery.

- Marine Applications:

- Large commercial vessels and naval ships: Orchestrating the monitoring of propulsion systems, auxiliary engines, and other critical machinery on board.

In essence, the CPUM facilitates the transformation of raw sensor data from individual monitoring modules into actionable information that can be used by operators, maintenance personnel, and plant control systems, thereby improving asset reliability, reducing downtime, and enhancing overall safety.

Related Products:

The VIBRO-METER VM600 CPUM 200-595-045-114 is part of a complete VM600 system and requires several other modules and components to function effectively.

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: The 19-inch rack housings where the CPUM (and its associated IOCN) are physically installed. The CPUM occupies slots in the front of the rack.

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power to the VM600 rack’s backplane and all installed modules, including the CPUM. Redundant RPS6U units are commonly used for high availability.

- Input/Output (I/O) Card (Companion to CPUM):

- VM600 IOCN: This is the essential companion card for the CPUM. It installs in the rear of the rack, directly behind the CPUM. The IOCN provides the physical connectors for Ethernet and serial communication, allowing the CPUM to interface with external networks and devices.

- Machinery Protection Modules (MPM):

- VM600 MPC4 / MPC4Mk2: These are the primary protection cards that measure vibration, position, and speed, and generate alarm/trip conditions. The CPUM communicates with these cards to gather their data and status.

- Condition Monitoring Modules (CMM):

- VM600 XMV16 / XMC16: For extended vibration monitoring and advanced analysis. The CPUM communicates with these modules, often via a dedicated internal Ethernet link, to retrieve their detailed data.

- Analog Monitoring Modules (AMM):

- VM600 AMC8 / AMC8Mk2: For monitoring process parameters like temperature and pressure. The CPUM also aggregates data from these modules.

- Relay Cards (Optional):

- VM600 RLC16 / RLC16Mk2: These provide additional configurable relay outputs. The CPUM manages the logic for triggering these relays based on alarms from other modules.

- Monitoring Software:

- VibroSight®: The comprehensive PC-based software suite used for configuring the entire VM600 system (via the CPUM), visualizing real-time and historical data (trends, waveforms, spectra), managing alarms, and performing advanced diagnostics.

- VM600 MPSx Software (MPS1, MPS2): Older configuration and visualization software packages specifically for protection cards (MPC4, AMC8) that communicate via the CPUM.

The CPUM, working in concert with these other modules, forms a complete and powerful solution for the continuous monitoring and protection of critical rotating machinery.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922