الوصف

Here’s a detailed response for the VIBRO-METER VM600-ABE040 204-040-100-011 DCS PLC Module:

Product Name

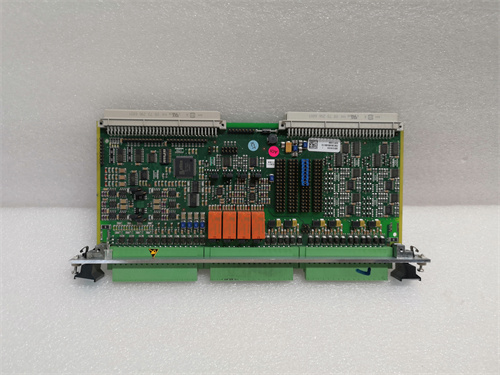

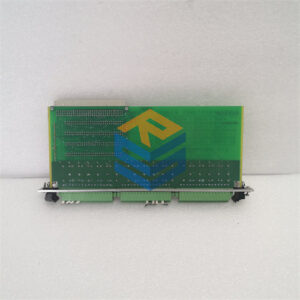

VIBRO-METER VM600-ABE040 204-040-100-011 DCS PLC Module

Product Description

The VIBRO-METER VM600-ABE040 204-040-100-011 is a high-performance Distributed Control System (DCS) and Programmable Logic Controller (PLC) module, designed to provide precise, reliable vibration monitoring and control for critical rotating machinery. As part of the VIBRO-METER VM600 series, the ABE040 204-040-100-011 module is engineered to help users monitor machine health, prevent failures, and optimize performance in complex industrial environments.

The module integrates seamlessly with the VIBRO-METER VM600 platform, enabling real-time data collection, processing, and reporting of vibration measurements from various sensors. It is widely used in industries such as power generation, oil & gas, mining, and industrial manufacturing, where reliable vibration monitoring is crucial to ensure machinery safety and performance.

Product Parameters & Specifications

- Model: VIBRO-METER VM600-ABE040 204-040-100-011

- Type: Vibration Monitoring and Control Module for DCS/PLC Systems

- Power Supply: 24V DC (Nominal)

- I/O Interface:

- Input Channels: Up to 4 vibration sensor inputs

- Output Channels: 4 (for controlling alarms, outputs, etc.)

- Signal Processing: Advanced signal processing algorithms for vibration data

- Communication:

- Fieldbus Communication: Profibus, Modbus

- Ethernet for integration with other systems

- Direct communication with VM600 system network

- Environmental Conditions:

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Humidity: 0% to 95%, non-condensing

- Accuracy: ±0.5% of full-scale range

- Data Logging: Supports local data storage for system diagnostics

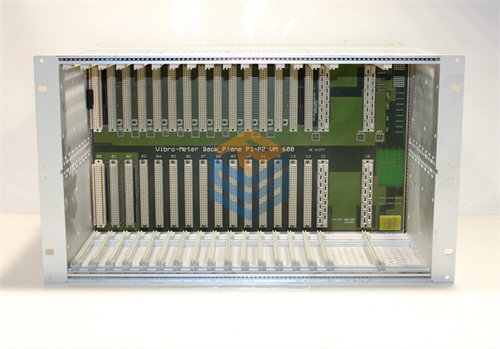

- Mounting Type: Rack-mounted for integration into control systems

- Diagnostics: Built-in self-diagnostics for real-time monitoring and troubleshooting

- Compliance: CE, UL, and other relevant safety certifications for industrial use

- Dimensions: 19” rack-mounted form factor

- Weight: Approx. 1.8 kg

Key Features

- Advanced Vibration Monitoring: The module processes vibration data from sensors to monitor the condition of rotating machinery, identifying potential issues such as imbalances, misalignments, or bearing wear.

- Real-Time Alarm Management: The module can trigger alarms based on predefined thresholds for vibration levels, providing early warning for maintenance actions.

- Seamless Integration: Designed to integrate easily with the VIBRO-METER VM600 system, enabling centralized control of all vibration monitoring activities within the plant.

- Multi-Channel Input: Capable of handling multiple vibration sensor inputs, allowing for comprehensive monitoring of different parts of machinery simultaneously.

- Signal Processing Capabilities: Provides advanced algorithms for analyzing vibration frequencies, amplitudes, and other critical parameters.

- Diagnostic and Maintenance Support: Features built-in diagnostics that provide detailed insights into system health and performance, helping users reduce downtime and increase operational efficiency.

- Reliability and Robustness: Built for use in harsh industrial environments, the VM600-ABE040 204-040-100-011 is capable of operating under a wide range of environmental conditions.

- Flexible Communication: Compatible with common communication protocols like Profibus, Modbus, and Ethernet, making it easy to integrate with existing PLC/DCS systems.

Applications and Use Cases

The VIBRO-METER VM600-ABE040 204-040-100-011 is designed for applications that require continuous, real-time monitoring of vibration levels in industrial machinery, such as:

- Power Generation Plants: Monitoring the health of turbines, compressors, and other critical machinery to prevent failure and improve uptime.

- Oil & Gas: Ensuring the safe operation of pumps, motors, and compressors in extraction and refining operations.

- Mining and Heavy Industry: Tracking the condition of crushers, conveyors, and other equipment that experiences high mechanical stress.

- Manufacturing Facilities: Protecting motors, fans, and pumps from wear, misalignment, and imbalance to extend the life of equipment.

Selection and Integration Considerations

When selecting the VIBRO-METER VM600-ABE040 204-040-100-011 for your system, consider the following:

- Number of Channels: Ensure the module’s number of vibration sensor input channels meets your monitoring needs (up to 4).

- Integration with Existing Systems: Ensure compatibility with other systems via supported communication protocols (e.g., Profibus, Modbus).

- Environmental Requirements: Consider the operating environment’s temperature, humidity, and potential for vibration or mechanical shock, ensuring the module is robust enough for your application.

- Maintenance Needs: Take advantage of the diagnostic features to streamline maintenance schedules and minimize downtime.

- Sensor Types: Verify that the vibration sensors you are using are compatible with the module’s input specifications.

For more detailed information or inquiries, you may contact VIBRO-METER or consult the product documentation for integration and installation guidelines.

Let me know if you’d like to refine any of the details or if you need further assistance!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922