الوصف

The user is asking about the VIBRO-METER VM600 MPC4 module with the specific part number 200-510-111-035.

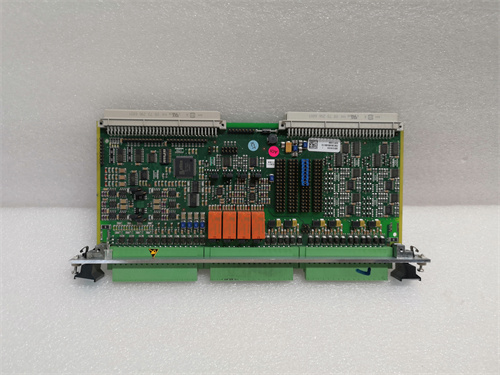

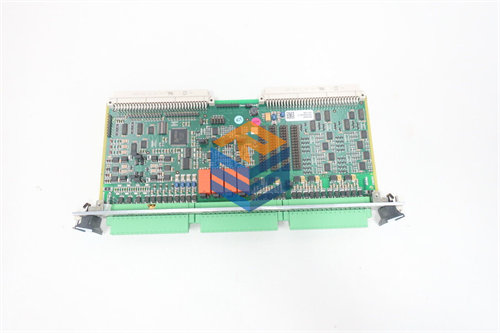

The VM600 MPC4 (Machinery Protection Card) is a fundamental component of the Vibro-Meter VM600 and VM600Mk2 series, primarily designed for machinery protection and basic condition monitoring of critical rotating equipment.

The part number 200-510-111-035 refers to a specific variant within the MPC4 family, which includes the original MPC4 and its subsequent generations like the MPC4Mk2. The “-035” suffix, compared to other variants like “-013” or “-019”, generally denotes specific configurations related to:

- Input Ranges or Filtering: Subtle differences in calibrated input ranges or default filter settings.

- Certifications: Potentially indicating a specific level of safety integrity (e.g., SIL 2) or compliance with particular regional standards.

- Hardware Revisions/Firmware: Minor updates to components or firmware that might not change the core functionality but warrant a distinct part number.

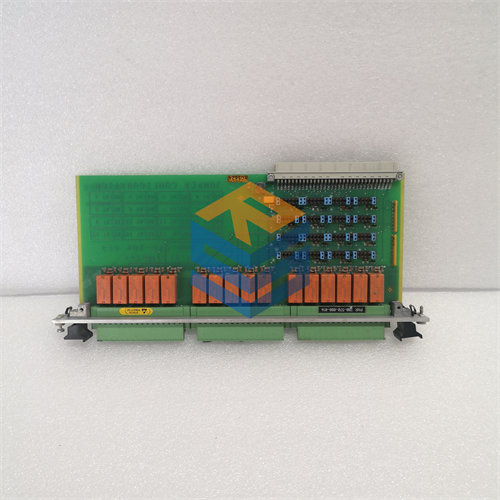

It’s important to note that the MPC4 (and MPC4Mk2) always operates as a card pair with a corresponding Input/Output (I/O) module, typically an IOC4T (for original MPC4) or IOC4Mk2 (for MPC4Mk2). The MPC4 handles the signal processing, alarm logic, and protection functions, while the IOC4T/IOC4Mk2 provides the physical sensor connections, transducer power, and the relay/analog outputs.

SEO Optimized Headings:

- VIBRO-METER VM600 MPC4 200-510-111-035: Precision Machinery Protection Card.

- VM600 MPC4: 4-Channel Dynamic & 2-Channel Tachometer Monitoring.

- VIBRO-METER 200-510-111-035: Configurable Protection for Rotating Machinery.

- VM600 Protection Module: API 670 Compliant Asset Safeguarding.

- MPC4 Industrial Controller: Real-time Alarm and Trip Logic.

- VIBRO-METER VM600 Series: Essential for Critical Machine Health.

Product Overview:

The VIBRO-METER VM600 MPC4 200-510-111-035 is a high-performance Machinery Protection Card (MPC) designed for the continuous, real-time measurement and monitoring of critical parameters on rotating machinery. It is a key component of the VM600 rack-based system, dedicated to protecting valuable assets from potential damage by detecting abnormal conditions rapidly and initiating alarms or shutdowns.

This specific MPC4 variant is capable of simultaneously processing signals from:

- Four dynamic channels: For vibration (relative or absolute), displacement, acceleration, velocity, or dynamic pressure.

- Two tachometer (speed) channels: For rotational speed and phase reference.

It applies sophisticated Digital Signal Processing (DSP) techniques, including filtering, integration, order tracking, and calculates various machinery health parameters. When configured alarm limits are exceeded, the module provides immediate relay outputs (via its companion I/O card) for warnings or automatic machinery trips, ensuring compliance with standards such as API 670.

Product Details:

The VIBRO-METER VM600 MPC4 200-510-111-035 module is a cornerstone of any robust machinery protection system. Its design focuses on high reliability and fast response times, critical for safeguarding expensive industrial assets and ensuring operational safety.

Consider a large centrifugal compressor in a petrochemical plant. Undetected excessive vibration could lead to catastrophic failure, resulting in immense financial loss, environmental damage, and potential safety hazards. The VM600 MPC4, as part of the overall monitoring system, actively monitors the compressor’s vibration levels, shaft position, and speed. If a pre-set “Danger” limit is crossed, the MPC4 can instantaneously trigger a relay, initiating an automatic shutdown of the compressor to prevent further damage.

Here’s a breakdown of its key functionalities and attributes:

1. Primary Function: Real-time Machinery Protection: * Continuous Monitoring: Constantly acquires and processes data from connected sensors without interruption. * Rapid Response: Designed for very low latency in alarm detection and relay activation, ensuring quick protective action. * Compliance: Adheres to industry standards like API 670, which outlines requirements for vibration, axial position, and other critical parameters for turbomachinery. Many MPC4 variants (especially MPC4Mk2) are also SIL 2 certified (Safety Integrity Level 2), making them suitable for demanding safety-instrumented system (SIS) applications.

2. Versatile Multi-Channel Inputs: * 4 Dynamic Inputs: Each channel is fully programmable and can connect to various types of dynamic transducers: * Proximity Probes: For relative shaft vibration (displacements) and axial (thrust) position. * Accelerometers: For absolute casing vibration. * Velocity Transducers: For absolute casing vibration. * Can also support other dynamic signals like dynamic pressure. * 2 Tachometer Inputs: Used to measure machine rotational speed and provide a phase reference (e.g., once-per-revolution signal). Compatible with proximity probes, magnetic pick-ups, or TTL signals, supporting fractional tachometer ratios.

3. Advanced Signal Processing Capabilities: * Digital Filtering: Features highly configurable digital filters (high-pass, low-pass, band-pass) to isolate specific frequency ranges for focused analysis and alarm triggering. * Integration/Differentiation: Can digitally integrate (e.g., acceleration to velocity, velocity to displacement) or differentiate signals as required by the measurement type. * Parameter Calculation: Computes key machinery health parameters in real-time, including: * Overall vibration (RMS, peak, peak-to-peak). * Filtered vibration (Smax, 1X, 2X, etc.). * Shaft eccentricity and position (gap). * Axial thrust position. * Absolute and differential housing expansion. * Order Tracking: Performs amplitude and phase monitoring in order-tracking mode, crucial for diagnosing speed-dependent machine faults.

4. Comprehensive Alarm and Output Management: * Programmable Alarms: Supports multiple alarm levels (typically “Alert” and “Danger”) with highly configurable setpoints, time delays (to prevent nuisance trips), hysteresis, and latching functions. Alarm levels can also be made adaptive based on speed or other external conditions. * Relay Outputs: Provides four user-configurable relays (via its companion IOC4T/IOC4Mk2 card) for remote indication (warning lights, horns) or machinery shutdown. An additional “OK” or “System Fault” relay is also typically available. * Analog Outputs: Offers four configurable analog outputs (e.g., 4-20 mA or 0-10 V) for interfacing with external control systems (DCS, PLC) or local indicators. * Buffered Raw Outputs: BNC connectors on the associated I/O card (IOC4T/IOC4Mk2) provide buffered raw sensor signals for connecting portable diagnostic equipment or oscilloscopes without disturbing the protection function.

5. Robust Diagnostics and Reliability: * “OK System” Monitoring: Continuously monitors the integrity of the sensor signal path, including wiring, transducer health, and signal levels, to detect faults like open circuits or short circuits. * Self-Test: Performs internal self-tests and diagnostics upon power-up and during operation to ensure hardware and firmware integrity. * Live Insertion/Removal: Supports hot-swapping within the VM600 rack, allowing modules to be inserted or removed without powering down the entire system (under certain conditions), simplifying maintenance.

6. System Integration: * The MPC4 module (installed in the front of a VM600 ABE04x rack) always functions as a card pair with a dedicated IOC4T or IOC4Mk2 I/O module (installed directly behind it in the rear). * It communicates with the rack’s CPU module (CPUR2/CPUM) via the VME bus for configuration via VibroSight® software and data exchange with external systems.

In essence, the VIBRO-METER VM600 MPC4 200-510-111-035 is a sophisticated, highly reliable module engineered to provide critical, real-time protection for rotating machinery, significantly contributing to operational safety and the longevity of high-value industrial assets.

Technical Specifications (Typical for VM600 MPC4 / MPC4Mk2, including 200-510-111-035 variant):

The specifications are generally consistent across the MPC4 family, with minor differences based on the exact part number/version (e.g., original MPC4 vs. MPC4Mk2, or specific sub-variants like -035).

Applications and Industries:

The VIBRO-METER VM600 MPC4 200-510-111-035 is a cornerstone for machinery protection in industries where asset reliability, operational safety, and uptime are paramount. Its ability to quickly detect and react to abnormal conditions makes it indispensable for critical rotating equipment.

Consider a large crude oil refinery. The integrity of its massive pumps and compressors is vital for continuous operation. A sudden pump bearing failure due to unnoticed vibration could lead to a massive spill, environmental disaster, and significant production losses. The VM600 MPC4, being API 670 compliant, is specifically designed for such applications. It continuously monitors the pump’s vibration and axial position. If a predefined “Danger” threshold is crossed, the MPC4 immediately activates a relay, which can then trigger an emergency shutdown of the pump, preventing further damage and ensuring site safety.

Key applications and industries that rely on the MPC4 include:

- Power Generation:

- Gas, Steam, and Hydro Turbines, Generators: Protecting these prime movers from shaft vibration, bearing issues, and axial position excursions to prevent catastrophic failures and ensure stable power supply.

- Large Fans and Pumps: Safeguarding critical balance-of-plant (BOP) equipment.

- Oil & Gas:

- Centrifugal and Reciprocating Compressors, Pumps, Gas Turbines: Essential for pipeline integrity, processing plants, and offshore platforms, where compliance with API 670 standards is often a strict requirement.

- LNG (Liquefied Natural Gas) Plants: Critical for the continuous operation of liquefaction trains.

- Chemical and Petrochemical Industries:

- Monitoring complex rotating machinery in hazardous environments where precise control and rapid shutdown capabilities are vital for safety and environmental protection.

- Heavy Manufacturing:

- Steel mills, paper mills, cement plants: Protecting large motors, gearboxes, and fans where downtime can significantly impact production schedules.

- Marine Applications:

- Large commercial vessels and naval ships: Monitoring propulsion engines, turbochargers, and other critical machinery to ensure safe navigation and operation.

In essence, the VM600 MPC4 is deployed wherever unplanned downtime is unacceptable, asset protection is critical, and human safety depends on the reliable operation of rotating machinery. It forms the first line of defense against mechanical failures, enabling effective predictive maintenance strategies and ensuring operational continuity.

Related Products:

The VIBRO-METER VM600 MPC4 200-510-111-035 is an integral part of a comprehensive VM600 system and requires several other modules and components to function as a complete monitoring solution.

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U (or 1U for ABE056) rack housings where the MPC4 module is physically installed (in the front card cage).

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power (+5 VDC, ±12 VDC) to the VM600 rack’s backplane and all installed modules, including the MPC4. Redundant RPS6U units are highly recommended for critical applications to ensure continuous power.

- Input/Output (I/O) Cards (Companion to MPC4):

- VM600 IOC4T / IOC4Mk2: This is the essential companion card for the MPC4. It installs in the rear of the rack, directly behind the MPC4, forming a “card pair.” The IOC4T/IOC4Mk2 handles the physical wiring connections from sensors, provides transducer power, offers buffered raw outputs, and contains the four user-configurable relays and four analog outputs that are controlled by the MPC4.

- Rack Controller and Communication Modules:

- VM600 CPUR2 / CPUM / CPUMMk2: These modules manage the overall VM600 rack, handle the configuration of the MPC4 via software, process system-level alarm logic, and provide communication interfaces (e.g., Ethernet, serial) to external systems like DCS, PLCs, or PC-based monitoring software.

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller, providing physical communication ports.

- Relay Cards (Optional):

- VM600 RLC16 / RLC16Mk2: If more than the four standard relays provided by the IOC4T/IOC4Mk2 are needed for complex alarm or shutdown logic, RLC16 cards can be added to the rack, with their relays controlled by the MPC4 via the rack’s communication bus.

- Analog Monitoring Modules (Optional):

- VM600 AMC8 / AMC8Mk2: For monitoring process parameters like temperature, pressure, or flow, complementing the vibration monitoring provided by the MPC4.

- Extended Condition Monitoring Modules (Optional):

- VM600 XMV16 / XMC16: For more in-depth vibration analysis (e.g., high-resolution FFTs) or specialized combustion monitoring, often used in conjunction with MPC4s for a complete protection and condition monitoring solution.

- Sensors:

- Various types of sensors are connected to the IOC4T/IOC4Mk2, including proximity probes (for displacement/axial position), accelerometers, velocity transducers, and tachometer sensors.

- Monitoring Software:

- VibroSight®: The comprehensive PC-based software suite used for configuring the entire VM600 system (including the MPC4), visualizing real-time and historical data (trends, waveforms, spectra), managing alarms, and performing advanced diagnostics.

- VM600 MPSx Software (MPS1, MPS2): Older configuration and visualization software packages specifically for protection cards (MPC4, AMC8) that communicate via the CPUM.

The MPC4, working in concert with these other modules, forms a complete and powerful solution for the continuous monitoring and protection of critical rotating machinery.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922