الوصف

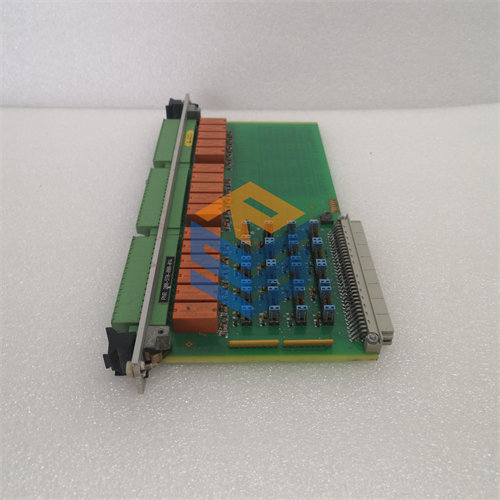

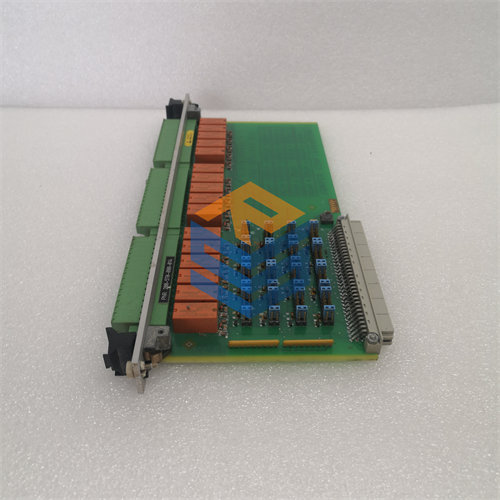

The VIBRO-METER VM600 XMV16 620-001-001-116 is a specialized vibration monitoring module designed for the Vibro-Meter VM600 series of machinery protection and condition monitoring systems. This particular module, often paired with an XIO16T input/output card, forms a powerful system for advanced vibration analysis.

The “XMV16” signifies its role as an Extended Vibration Monitoring module with 16 dynamic channels. The detailed part number 620-001-001-116 specifies its exact configuration and features.

SEO Optimized Headings:

- VIBRO-METER VM600 XMV16 620-001-001-116: 16-Channel Vibration Monitoring Module.

- VM600 XMV16: Advanced Condition Monitoring for Rotating Machinery.

- VIBRO-METER 620-001-001-116: High-Resolution Vibration Analysis Card.

- VM600 Extended Vibration Monitoring: Precision Data Acquisition for Turbines.

- XMV16 Module: Real-time FFT Analysis for Industrial Assets.

- VIBRO-METER VM600 Series: Centralized Machinery Protection Systems.

Product Overview:

The VIBRO-METER VM600 XMV16 620-001-001-116 is a high-performance processing module within the VM600 system. It’s specifically engineered for extended vibration monitoring and condition monitoring applications on critical rotating machinery. This module is typically used in conjunction with an XIO16T (or similar) input/output card, which handles the physical sensor connections and signal conditioning.

The XMV16 module excels in providing comprehensive vibration data by offering:

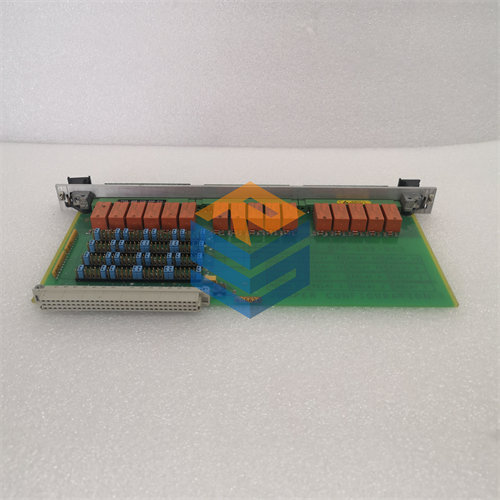

- High Channel Density: It provides 16 independent dynamic (vibration) channels and 4 tachometer (speed) channels, all of which are individually configurable.

- Advanced Signal Processing: It performs analog-to-digital conversion (24-bit ADC) and extensive digital signal processing functions, including waveform acquisition, spectral analysis (FFT), and various processed outputs.

- Flexible Data Acquisition: Supports simultaneous acquisition of all channels via asynchronous (fixed frequency) or synchronous (order-tracked) sampling, making it versatile for different monitoring needs.

- High-Resolution FFT: Capable of generating high-resolution Fast Fourier Transform (FFT) spectra (up to 6400 lines in 500 ms) for detailed vibration analysis.

- Extensive Outputs: Offers up to 20 configurable processed outputs per dynamic channel, providing various vibration parameters (RMS, peak, peak-to-peak, DC gap, etc.).

Product Details:

The VIBRO-METER VM600 XMV16 620-001-001-116 module is a sophisticated component designed to deliver precise insights into the vibrational behavior of critical machinery. Imagine a large power plant where the health of steam turbines and generators directly impacts energy production. Unforeseen vibration issues can lead to catastrophic failures, costly downtime, and safety hazards. The VM600 XMV16 plays a vital role here by continuously monitoring the machinery’s vibrations, detecting anomalies early, and providing the data necessary for predictive maintenance.

Here’s a breakdown of its key functionalities and attributes:

1. Core Functionality: Extended Vibration Monitoring: * Unlike basic protection modules (like the MPC4Mk2), the XMV16 focuses on condition monitoring, providing detailed, high-resolution data for in-depth analysis of machinery health. * It acquires raw vibration signals from various sensors (accelerometers, proximity probes, velocity transducers) connected through its companion I/O module. * It also supports tachometer inputs for speed measurement, which is crucial for order tracking and analyzing vibration characteristics relative to machine speed.

2. High-Performance Data Acquisition and Processing: * 16 Dynamic Channels & 4 Tachometer Channels: This high channel density makes it suitable for monitoring complex machines with multiple measurement points. Each channel is independently configurable. * 24-bit Analog-to-Digital Conversion (ADC): Ensures high precision and resolution in converting analog sensor signals into digital data. * High Signal-to-Noise Ratio (SNR): Facilitates accurate measurements even in noisy industrial environments. * Flexible Sampling Modes: * Asynchronous (Fixed Frequency) Sampling: Collects data at a constant rate, suitable for general vibration monitoring and detecting changes in overall vibration levels. * Synchronous (Order-Tracked) Sampling: Synchronizes data acquisition with the machine’s rotational speed, essential for analyzing vibration components that are multiples (orders) of the rotational speed, which often indicate specific mechanical issues. * Real-time FFT Processing: The module performs Fast Fourier Transforms onboard, converting time-domain vibration signals into frequency-domain spectra. This allows engineers to identify specific frequencies associated with bearing faults, gear mesh problems, unbalance, or misalignment. High-resolution FFTs (e.g., up to 6400 lines) provide granular detail for fault diagnosis.

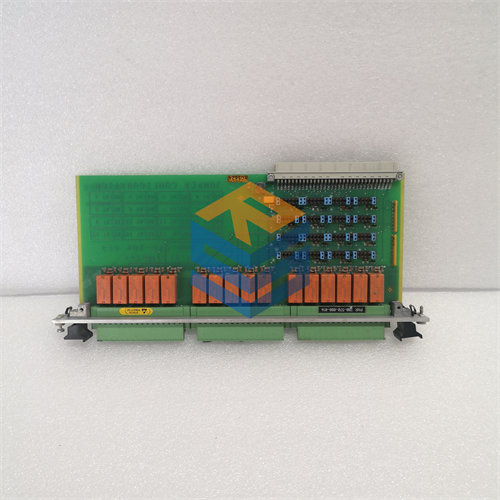

3. Integration and Communication: * The XMV16 module is typically paired with an XIO16T Input/Output card. The XIO16T handles signal conditioning, EMI protection, and provides terminal connections for the sensors. The XMV16 then performs the digital signal processing. * It integrates seamlessly into a VM600 system rack (such as ABE040 or ABE042), connecting via the VMEbus backplane for power and communication with other system modules like the Rack Controller (CPUR2/CPUM) and communication interfaces (IOCN). * Data from the XMV16 can be communicated to a central monitoring station running VibroSight® software via Ethernet, enabling comprehensive data visualization, trend analysis, alarm management, and configuration.

4. Outputs and Alarms: * The module can generate numerous processed outputs (up to 20 per channel), including RMS, peak, peak-to-peak, true peak, true peak-to-peak, and DC (gap) values. These outputs can be configured to represent specific vibration bands. * It supports multiple alarms per processed output with configurable limits, hysteresis, and time delays, allowing for early warning and precise triggering of alerts.

In essence, the VIBRO-METER VM600 XMV16 620-001-001-116 is a sophisticated “brain” within the VM600 system, transforming raw sensor data into actionable insights for effective machinery diagnostics and predictive maintenance strategies.

Technical Specifications (Typical for XMV16 620-001-001-116):

The exact specifications for the “620-001-001-116” variant might have minor differences, but the core capabilities of the XMV16 are as follows:

Applications and Industries:

The VIBRO-METER VM600 XMV16 620-001-001-116 is specifically designed for high-performance vibration monitoring and is deployed in industries where the reliable operation of large, critical rotating machinery is paramount.

Consider an oil and gas refinery where massive compressors are indispensable for processing hydrocarbons. A sudden failure of these compressors due to undetected vibration issues could lead to plant shutdowns, environmental hazards, and significant financial losses. The VM600 XMV16, in this scenario, would continuously acquire high-resolution vibration data from various points on the compressor, perform real-time analysis, and feed this data to engineers. This allows them to monitor subtle changes in vibration signatures, diagnose potential issues like bearing wear or impeller imbalance long before they become critical, and schedule maintenance proactively.

Here are some key applications and industries:

- Power Generation:

- Gas, Steam, and Hydro Turbines: Monitoring turbine and generator vibrations, shaft eccentricity, and axial position for optimal performance, efficiency, and safety.

- Balance-of-Plant (BOP) Equipment: Large fans, pumps, and motors.

- Oil & Gas:

- Compressors (Centrifugal, Reciprocating), Pumps, and Fans: Monitoring critical rotating equipment in pipelines, processing plants, and offshore platforms.

- Compliance with API 670 Standard: The VM600 system, including modules like the XMV16, is designed to meet the rigorous requirements of API 670 for machinery protection.

- Chemical and Petrochemical Industries:

- Monitoring reactors, mixers, and other rotating equipment where precise control and safety are critical due to the nature of the materials processed.

- Heavy Industries (Steel, Mining, Cement):

- Monitoring large crushers, mills, blowers, and other heavy-duty machinery where vibrations can indicate wear, misalignment, or structural issues.

- Marine Applications:

- Monitoring propulsion systems, generators, and auxiliary machinery on large vessels and offshore installations.

- Test and Development Facilities:

- Used in R&D settings for detailed vibration analysis of prototypes or new machinery designs.

In summary, the VM600 XMV16 is a powerful tool for predictive maintenance and asset management, enabling industries to extend equipment lifespan, optimize performance, reduce maintenance costs, and prevent catastrophic failures.

Related Products:

To function as a complete monitoring solution, the VIBRO-METER VM600 XMV16 620-001-001-116 module typically integrates with several other components within the Vibro-Meter VM600 ecosystem:

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U rack housings that the XMV16 (and its companion I/O module) are physically installed into.

- Input/Output (I/O) Cards:

- XIO16T: This is the most common companion I/O card for the XMV16. It handles the physical wiring connections from the sensors, signal conditioning, and provides buffered raw signals. The XMV16 and XIO16T together form a “card pair.”

- Power Supply Units (PSU):

- RPS6U: These units provide the necessary DC power to the VM600 rack’s backplane and all installed modules, including the XMV16. Redundant RPS6U units are often used for critical applications.

- Rack Controller and Communication Modules:

- CPUR2, CPUM: These modules manage the rack and provide communication interfaces to external systems (e.g., DCS, PLC, or a PC running VibroSight software).

- IOCN: An I/O communication module that might be used with a CPUR2.

- Machinery Protection Modules (MPM):

- MPC4Mk2: While XMV16 focuses on condition monitoring, the MPC4Mk2 is for machinery protection, providing fast, hardwired shutdown capabilities based on predefined alarm limits. In many systems, both XMV16 and MPC4Mk2 modules are present to offer both detailed monitoring and robust protection.

- Sensors:

- Proximity Probes: For relative shaft vibration and axial position.

- Accelerometers: For casing vibration.

- Velocity Transducers: For casing vibration at lower frequencies.

- Tachometer Sensors: For rotational speed and phase reference.

- Monitoring Software:

- VibroSight®: This is the primary software suite from Parker Meggitt used for configuring the VM600 system, visualizing data (waveforms, trends, spectra), managing alarms, and performing in-depth analysis. It communicates with the VM600 system via Ethernet.

The XMV16, in combination with these components, forms a comprehensive and highly reliable system for ensuring the long-term health and safe operation of critical industrial machinery.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922