الوصف

The user is asking about the VIBRO-METER VM600 RLC16 module, providing two part numbers: 200-570-000-111 and 200-570-101-015.

Based on the search results, the RLC16 is a Relay Card that serves as an optional module within the Vibro-Meter VM600 and VM600Mk2 series of machinery protection and condition monitoring systems.

It appears that 200-570-000-111 is the primary part number for the RLC16 relay card itself, while 200-570-101-015 seems to refer to a specific variant or a related terminal block or accessory. Many suppliers list both numbers together, suggesting they are either bundled or represent a slight configuration difference. Without a direct cross-reference from official documentation for these two specific part numbers, it’s most likely that the -111 is the core module and the -015 specifies a particular build or included connector set.

SEO Optimized Headings:

- VIBRO-METER VM600 RLC16 200-570-000-111: 16-Channel Relay Card for Machinery Protection.

- VM600 RLC16: Auxiliary Relay Outputs for Industrial Monitoring Systems.

- VIBRO-METER 200-570-101-015: Configurable Relays for VM600 Alarms.

- VM600 Relay Module: Enhanced Control for Critical Rotating Equipment.

- RLC16 Relay Card: Hardware Configurable Relays (NE/NDE).

- VIBRO-METER VM600 Series: Extending Alarm Outputs for MPS/CMS.

Product Overview:

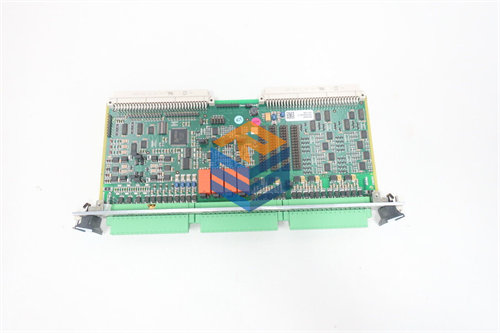

The VIBRO-METER VM600 RLC16 is a relay module designed to provide additional user-configurable relay outputs within a VM600 (or VM600Mk2) rack-based machinery protection system. Its primary function is to expand the number of physical relay contacts available beyond what is typically provided by the main protection or monitoring cards (e.g., MPC4Mk2/IOC4Mk2, which usually have 4 relays).

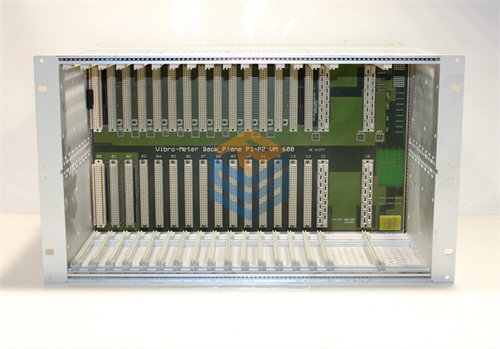

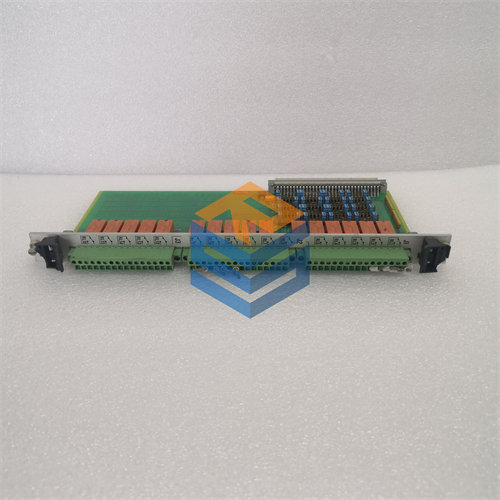

The RLC16 module features 16 independent relays with changeover contacts (SPDT – Single Pole Double Throw), making it highly versatile for various alarm, shutdown, or interlocking applications. It is installed in the rear of a VM600 system rack (such as ABE04x or ABE056) and connects directly to the rack’s backplane.

Product Details:

The VIBRO-METER VM600 RLC16 module plays a crucial role in enhancing the output capabilities of a VM600 machinery protection and condition monitoring system. In critical industrial applications, when an anomaly is detected (e.g., high vibration, elevated temperature), the system needs to trigger external actions such as alarming operators, shutting down machinery, or activating interlocks. While main monitoring cards provide some relays, complex systems often require more.

Imagine a large industrial compressor station. Each compressor might be monitored by a VM600 system. If a critical vibration limit is exceeded, you might need to:

- Sound a local alarm horn.

- Flash a warning light in the control room.

- Send a signal to the Distributed Control System (DCS).

- Activate an automatic shutdown sequence.

- Trigger a fire suppression system (in hazardous areas).

Each of these actions could require a separate relay output. The RLC16 steps in to provide this necessary expansion.

Here’s a breakdown of its key features and how it functions:

1. Expansion of Relay Outputs: * The core purpose of the RLC16 is to supplement the relay outputs available from primary protection modules like the MPC4Mk2 (which typically provides 4 relays via its IOC4Mk2 companion card). * It provides 16 additional independent relays per module, significantly increasing the system’s ability to trigger various external devices or control sequences.

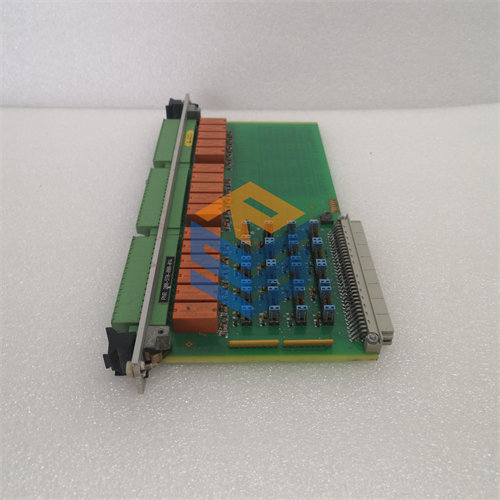

2. Relay Characteristics and Configuration: * Type: Each of the 16 relays is a Single Pole Double Throw (SPDT) contact, meaning it has a Common (COM) terminal, a Normally Open (NO) terminal, and a Normally Closed (NC) terminal. This provides flexibility in wiring to control devices that require either a circuit to close or open upon activation. * Contact Ratings: The relays are robust, typically rated for: * Nominal Rated Voltage: 250 VAC * Nominal Rated Current: 5 AAC * Maximum Breaking Capacity: 1250 VA (without contact protection). * DC Load Breaking Capacity: Specific curve provided in datasheets, generally up to 70 VDC / 33 VAC (RMS) in certain rack configurations. * Configurability: The relays are hardware configurable as either Normally Energized (NE) or Normally De-energized (NDE) via jumpers on the card. * Normally Energized (NE) / “De-energise to Trip”: In the normal operating state (no alarm), the relay coil is energized, and the COM contact is connected to the NO terminal. If power is lost or an alarm condition occurs, the coil de-energizes, and the COM contact switches to the NC terminal. This is often preferred for critical safety applications as a “fail-safe” mechanism – a power failure or system fault will automatically trigger the alarm/shutdown. * Normally De-energized (NDE) / “Energise to Trip”: In the normal operating state, the relay coil is de-energized, and the COM contact is connected to the NC terminal. Upon an alarm, the coil energizes, and the COM contact switches to the NO terminal. * Fast Response: Typical operate/release times are in the order of 8 milliseconds.

3. Integration within the VM600 Rack: * The RLC16 is a single-width module that installs in the rear of a VM600 system rack (e.g., ABE040, ABE042, ABE056). * It connects directly to the rack’s backplane via a single connector, drawing +5 VDC power from the rack’s power supply (RPS6U). * The relay contacts are accessible externally via screw-terminal connectors at the rear of the VM600 rack, simplifying wiring to field devices. * The relays are controlled by open-collector drivers under software control, meaning their state is managed by the rack’s CPU module (CPUR2/CPUM) based on the alarm logic defined for the various monitoring cards (MPC4Mk2, AMC8, etc.). * It supports a “system-wide safety line” that can drive all system relays (including those on IOC4Mk2 and RLC16) to a safe state if a critical system fault occurs.

4. Diagnostics and Reliability: * The RLC16 (especially the Mk2 version) often includes diagnostics (BIST – Built-In Self-Test) to monitor the state (coil voltage) of its own local relays for correct operation. This ensures they are consistent with control signals and are energizing/de-energizing as expected. * It is designed for high reliability, with a mechanical life of 15 x 10^6 operations and an electrical life of >10^5 operations.

In summary, the VIBRO-METER VM600 RLC16 is an essential expansion module for complex machinery protection systems. It provides the necessary capacity and flexibility for managing numerous alarm and control actions, contributing significantly to the overall safety and reliability of industrial operations.

Technical Specifications (Typical for RLC16 200-570-000-111, often accompanied by 200-570-101-015 for specific wiring or as a variant):

The information below consolidates typical specifications for the VM600 RLC16 based on available datasheets. The exact details might vary slightly between the -111 and -015 variants, but the core functionality remains consistent.

Applications and Industries:

The VIBRO-METER VM600 RLC16 is used in applications requiring an extended number of discrete output signals for alarming, control, or interlocking based on machinery condition or protection system status. Its robust design and configurable relays make it suitable for a wide range of critical industrial environments.

Consider a large oil and gas pipeline pumping station. Beyond basic alarms for individual pumps, the control system might need to trigger numerous actions across the facility: activate backup pumps, open/close specific valves, send signals to a remote control center, initiate fire suppression, or illuminate various status panels. The standard relays on individual monitoring cards might not be enough. The RLC16 provides the necessary expansion for these complex interlocking and signaling requirements.

Key applications and industries include:

- Machinery Protection Systems (MPS):

- Providing additional shutdown relays for critical machinery (turbines, compressors, large motors) when the inherent relays on protection cards (e.g., MPC4Mk2) are insufficient.

- Implementing voting logic or complex shutdown sequences requiring multiple independent contacts.

- Condition Monitoring Systems (CMS):

- Triggering external alarms (lights, horns, annunciators) based on condition changes (e.g., early warning of bearing degradation from vibration analysis).

- Activating data acquisition systems or initiating specialized diagnostic routines when specific thresholds are met.

- Process Control Integration:

- Sending status signals (e.g., “Machine Running,” “Alarm Active,” “Trip Imminent”) to Distributed Control Systems (DCS) or Programmable Logic Controllers (PLC) for overall plant control and visualization.

- Interlocking machinery operation with other plant processes (e.g., preventing a pump from starting if a certain valve is closed).

- Safety Instrumented Systems (SIS): While VM600 itself can be part of a SIS (e.g., SIL-rated MPC4Mk2 modules), the RLC16 contributes to the overall safety function by providing reliable, dedicated contacts for safety-related actions like emergency shutdowns.

- Industries:

- Power Generation: Thermal, Hydro, Nuclear Power Plants (turbines, generators, fans, pumps).

- Oil & Gas: Refineries, pipelines, offshore platforms (compressors, pumps, blowers).

- Chemical & Petrochemical: Chemical processing plants (reactors, mixers, critical pumps).

- Heavy Manufacturing: Steel mills, paper mills, cement plants (large motors, mills, crushing equipment).

- Marine: Large vessels, propulsion systems.

In essence, the RLC16 extends the “actionable” capabilities of the VM600 system, allowing it to interface more broadly with plant control systems and safety protocols, thereby enhancing operational efficiency and safety.

Related Products:

The VIBRO-METER VM600 RLC16 operates as an integral part of a larger VM600 system. Here are the key related products it commonly interfaces with:

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U (or 1U for ABE056) rack housings where the RLC16 is installed, typically in the rear slots.

- Rack Power Supply Units (PSU):

- RPS6U: Provides the necessary +5 VDC power to the RLC16 and all other modules via the rack’s backplane.

- Machinery Protection Modules (MPM):

- MPC4Mk2: These are the core protection cards (often paired with IOC4Mk2) that process sensor data and generate alarm/trip conditions. The RLC16 receives its control signals from these modules (via the CPUR2/CPUM) to activate its relays.

- Analog Monitoring Modules (AMM):

- AMC8 (and its companion IOC8T): Similar to MPC4Mk2, but for analog inputs like temperature or pressure. Alarms generated by these modules can also drive RLC16 relays.

- Rack Controller and Communication Modules:

- CPUR2, CPUM: These modules act as the “brain” of the VM600 rack, managing the configuration of all modules, processing alarm logic, and providing the control signals that ultimately activate the RLC16’s relays.

- IOCN: The I/O communication module associated with CPUM, which also plays a role in system-wide control signals.

- Input/Output (I/O) Cards for Protection Modules:

- IOC4Mk2 (for MPC4Mk2): These I/O cards typically provide a few (e.g., 4) built-in relays. The RLC16 is used when these internal relays are not sufficient.

- IOC8T (for AMC8): Similar to IOC4Mk2 but for AMC8 modules.

- Monitoring Software:

- VibroSight®: The software suite used to configure the RLC16’s relay logic, assign alarms from specific monitoring channels to specific relays, and monitor the overall system status.

- Field Devices:

- External devices connected to the RLC16’s screw terminals, such as alarm lights, horns, solenoids for shutdown valves, signals to DCS/PLC systems, and interlock circuits.

The RLC16 is a critical enabling component, providing the physical interface for the VM600 system to interact with and control the wider plant environment based on sophisticated machinery health monitoring

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922