الوصف

The user is asking about the VIBRO-METER VM600 MPC4 module, providing two part numbers: 200-510-017-019 and 200-510-111-013.

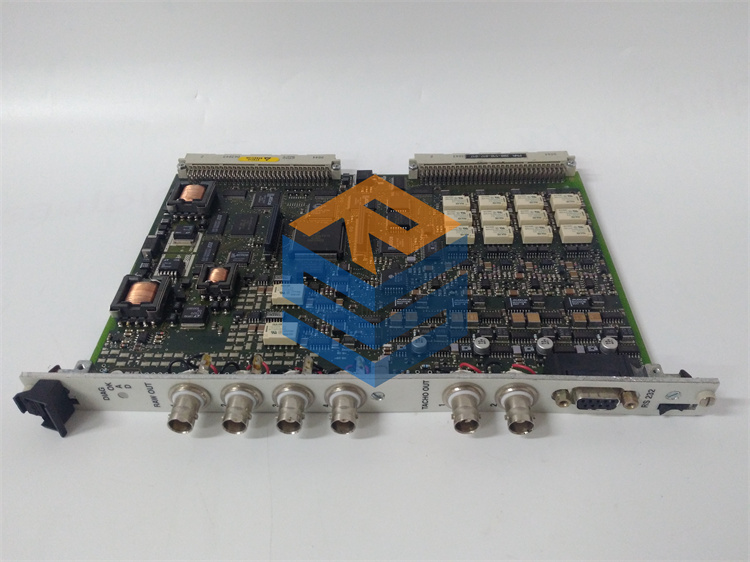

The VM600 MPC4 (Machinery Protection Card) is a core component of the Vibro-Meter VM600 and VM600Mk2 series, designed for machinery protection and basic condition monitoring of critical rotating equipment.

The part numbers 200-510-017-019 and 200-510-111-013 both refer to different variants or generations of the MPC4 module. While precise details for each specific sub-variant can be elusive without direct factory documentation, general characteristics and differences can be inferred:

- The MPC4 (and its successor, MPC4Mk2) is a processing module that always operates as a card pair with a corresponding Input/Output (I/O) module, typically an IOC4T or IOC4Mk2. The MPC4 processes the signals, and the IOC4T/IOC4Mk2 handles the physical sensor connections, signal conditioning, and provides outputs (relays, analog outputs).

- The numbers likely differentiate between the original MPC4 and a later revision (like the MPC4Mk2), or different internal configurations (e.g., input range, filtering options, or specific certifications/features that vary by order code). It’s common for the “Mk2” versions to offer enhanced diagnostics, slightly improved performance, and compliance with newer standards (like SIL 2 approval for safety-critical applications).

SEO Optimized Headings:

- VIBRO-METER VM600 MPC4 200-510-017-019: Machinery Protection Card for Critical Assets.

- VM600 MPC4 200-510-111-013: Advanced Vibration Monitoring and Protection Module.

- VIBRO-METER MPC4: API 670 Compliant Machinery Protection System.

- VM600 Protection Module: Real-time Monitoring for Turbines and Compressors.

- MPC4 Card: 4-Channel Dynamic and 2-Channel Tachometer Protection.

- VIBRO-METER VM600 Series: Preventing Failures in Rotating Machinery.

Product Overview:

The VIBRO-METER VM600 MPC4 is a high-performance Machinery Protection Card (MPC). It is the central processing unit for monitoring and protecting rotating machinery by continuously measuring and analyzing various dynamic and static parameters. It typically operates as a card pair with a corresponding I/O module (e.g., IOC4T or IOC4Mk2) within a VM600 system rack.

The MPC4 is designed to:

- Measure four dynamic channels (e.g., vibration, displacement, acceleration, velocity).

- Measure two tachometer channels (for speed and phase reference).

- Perform real-time signal processing, including digital filtering, integration/differentiation, and alarm logic.

- Trigger configurable alarms and initiate relay outputs for machinery shutdown or warning.

The specific part numbers 200-510-017-019 and 200-510-111-013 represent different configurations or versions of this critical module, potentially reflecting various input types, certifications (like SIL 2 for safety applications), or minor feature enhancements between production batches or generations (e.g., original MPC4 vs. MPC4Mk2).

Product Details:

The VIBRO-METER VM600 MPC4 is a cornerstone of machinery protection systems in industries where the continuous and safe operation of critical rotating equipment is essential. Its primary role is to act as a digital watchdog, constantly monitoring key parameters and reacting instantaneously to prevent catastrophic failures.

Imagine a large industrial gas turbine that is crucial for energy production. If a bearing starts to fail or the shaft experiences excessive vibration, swift action is needed to prevent extensive damage. The VM600 MPC4, integrated into the overall VM600 system, is designed precisely for this scenario: it continuously monitors the turbine’s vibration, compares it against predefined safe limits, and, if these limits are exceeded, can immediately trigger an alarm or even an automatic shutdown, protecting the asset and personnel.

Here’s a breakdown of its key features and functionalities:

1. Core Function: Machinery Protection: * The MPC4’s primary goal is real-time, continuous protection. It processes sensor signals with very low latency to detect anomalous conditions as they develop. * It adheres to industry standards for machinery protection, most notably API 670, which specifies requirements for vibration, axial position, and other parameters on critical turbomachinery. * Different versions (e.g., MPC4Mk2) can be SIL 2 certified (Safety Integrity Level 2 according to IEC 61508 and ISO 13849), making them suitable for use in safety-instrumented systems.

2. Multi-Channel Monitoring: * 4 Dynamic Channels: Fully programmable to accept signals from various transducers, including: * Proximity Probes: For relative shaft vibration (displacements) and axial position (thrust). * Accelerometers: For absolute casing vibration. * Velocity Transducers: For absolute casing vibration (often for lower frequencies). * Can also support other dynamic inputs like dynamic pressure. * 2 Tachometer (Speed) Channels: Used to measure rotational speed and provide phase reference. These inputs can come from proximity probes, magnetic pick-ups, or TTL signals, supporting fractional tachometer ratios for complex machinery.

3. Advanced Signal Processing: * Digital Signal Processing (DSP): Utilizes state-of-the-art DSP techniques for real-time measurement and monitoring. * Programmable Filters: Includes broadband and narrowband filters (high-pass, low-pass, band-pass) to isolate specific frequency components for analysis. * Integration/Differentiation: Can integrate acceleration signals to velocity or displacement, or differentiate displacement to velocity or acceleration, as required. * Measurement Parameters: Calculates a wide range of physical parameters, including: * Overall vibration (RMS, peak, peak-to-peak). * Smax (highest peak-to-peak filtered vibration in a broadband frequency range). * Eccentricity (relative displacement of the shaft centerline). * Thrust position (axial displacement of the shaft). * Absolute and differential housing expansion. * Gap (DC voltage from proximity probes indicating average position). * Order Tracking: Performs simultaneous amplitude and phase monitoring in order-tracking mode, allowing for analysis of vibration components that are multiples of the machine’s rotational speed.

4. Alarm and Output Management: * Programmable Alarms: Multiple alarm levels (e.g., Alert, Danger) with fully programmable setpoints, time delays, hysteresis, and latching functions. Alarm levels can also be adaptive, adjusting based on speed or other external conditions. * Relay Outputs: Typically provides 4 user-configurable relays (via its companion IOC4T/IOC4Mk2 card) for remote indication of alarm/status or for initiating shutdowns. An additional common circuit-fault relay is often included. * Analog Outputs: Provides 4 configurable analog outputs (0-10 V or 4-20 mA) for interfacing with Distributed Control Systems (DCS) or PLCs. * Buffered Outputs: Front-panel BNC connectors on the associated I/O card (IOC4T/IOC4Mk2) provide buffered “raw” transducer signals for portable diagnostic equipment.

5. Diagnostics and Reliability: * Self-Test and Diagnostics: Performs self-tests and diagnostic routines upon power-up and continuously monitors sensor OK status (e.g., for broken transmission lines or faulty sensors). * “OK System”: Built-in “OK system” monitors signal levels and wiring integrity. * High Reliability: Designed for continuous online operation in demanding industrial environments.

6. Integration: * The MPC4 module (installed in the front of a VM600 ABE04x rack) always works in tandem with an IOC4T or IOC4Mk2 I/O module (installed in the rear). This forms a “card pair.” * It communicates with the rack’s CPU (CPUR2/CPUM) via the VME bus for configuration via VibroSight® software and data exchange.

Relationship between 200-510-017-019 and 200-510-111-013: These are likely different part numbers representing:

- Different Generations: One might be the original MPC4, and the other a later revision or an MPC4Mk2 variant. The MPC4Mk2 typically has enhanced diagnostics (BIST), often higher SIL ratings, and possibly minor performance improvements.

- Specific Configurations: They could denote variations in default settings, specific factory-calibrated ranges, or minor hardware differences (e.g., component revisions) that justify a unique part number.

- Regional Variants or Included Accessories: Less likely for a core module, but sometimes part numbers can differentiate based on regional certifications or bundled accessories (though for MPC4, this is usually covered by the I/O card).

Without direct factory cross-reference documents for these exact legacy part numbers, assuming they are functionally similar core MPC4 modules with minor differences based on their exact manufacturing batch or specific customer order configuration is the most reasonable interpretation.

Technical Specifications (Typical for VM600 MPC4 / MPC4Mk2):

The following specifications are general for the MPC4 family of cards. Specific values may vary slightly between the -017-019 and -111-013 variants, and between the original MPC4 and the MPC4Mk2.

Applications and Industries:

The VIBRO-METER VM600 MPC4 is a vital component in protecting high-value and critical rotating machinery across numerous heavy industries. Its ability to provide continuous, real-time monitoring and rapid protective actions is invaluable.

Consider a large Liquefied Natural Gas (LNG) plant. The facility relies on massive, high-speed turbocompressors to liquefy natural gas. Any unplanned shutdown is incredibly costly and potentially hazardous. An MPC4 module would be dedicated to each critical compressor train, continuously monitoring its shaft vibration, bearing temperatures (via other modules), and axial position. If any parameter exceeds its “Danger” limit, the MPC4 can initiate a rapid and controlled shutdown sequence, preventing catastrophic damage to the multi-million dollar equipment and ensuring the safety of the plant.

Key applications and industries include:

- Power Generation:

- Gas Turbines, Steam Turbines, Hydro Turbines, Generators: Monitoring shaft vibration, bearing wear, axial position, and speed to prevent damage and ensure reliable energy production.

- Balance-of-Plant (BOP) Equipment: Large fans, pumps, and motors crucial for power plant operation.

- Oil & Gas:

- Centrifugal and Reciprocating Compressors, Pumps, Gas Turbines: Protecting critical machinery in refineries, pipelines, offshore platforms, and LNG facilities. Often used to meet API 670 requirements for machinery protection systems.

- Chemical and Petrochemical Industries:

- Monitoring reactors, mixers, and other high-speed rotating equipment in processes involving hazardous materials, where safety is paramount.

- Heavy Manufacturing:

- Steel mills, paper mills, cement plants: Protecting large motors, gearboxes, and fans where continuous operation is critical to production.

- Marine Industry:

- Large commercial vessels and naval ships: Monitoring propulsion engines, turbochargers, and auxiliary machinery.

In essence, the VM600 MPC4 is deployed wherever unplanned downtime is unacceptable, asset protection is critical, and human safety depends on the reliable operation of rotating machinery. It forms the first line of defense against mechanical failures, enabling effective predictive maintenance and ensuring operational continuity.

Related Products:

The VIBRO-METER VM600 MPC4 does not operate in isolation; it is a key component within a larger VM600 system. Here are the crucial related products it interacts with:

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U (or 1U for ABE056) rack housings that physically contain the MPC4 module (installed in the front).

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power to the VM600 rack’s backplane and all installed modules, including the MPC4. Redundant RPS6U units are highly recommended for critical applications.

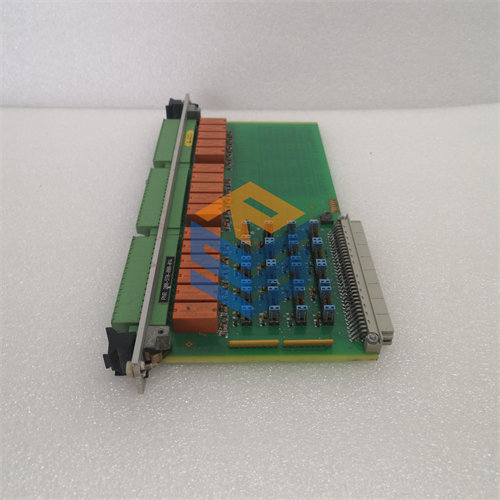

- Input/Output (I/O) Cards (Companion to MPC4):

- VM600 IOC4T / IOC4Mk2: This is the essential companion card for the MPC4. It installs in the rear of the rack, directly behind the MPC4. The IOC4T/IOC4Mk2 handles the physical wiring connections from sensors, signal conditioning, provides transducer power, offers buffered raw outputs, and contains the 4 user-configurable relays and 4 analog outputs controlled by the MPC4.

- Rack Controller and Communication Modules:

- VM600 CPUR2 / CPUM / CPUMMk2: These modules manage the overall VM600 rack, handle configuration of the MPC4 via software, process system-level alarm logic, and provide communication interfaces (e.g., Ethernet) to external systems like DCS, PLCs, or PC-based monitoring software.

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller.

- Relay Cards (Optional):

- VM600 RLC16 / RLC16Mk2: If more than the 4 standard relays provided by the IOC4T/IOC4Mk2 are needed, RLC16 cards can be added to the rack, controlled by the MPC4 via the rack’s communication bus.

- Analog Monitoring Modules (Optional):

- VM600 AMC8 / AMC8Mk2: For monitoring process parameters like temperature, pressure, or flow, complementing the vibration monitoring of the MPC4.

- Extended Condition Monitoring Modules (Optional):

- VM600 XMV16: For more in-depth vibration analysis (e.g., high-resolution FFTs) than what the MPC4 provides.

- Sensors:

- Various types of sensors are connected to the IOC4T/IOC4Mk2, including proximity probes (for displacement/axial position), accelerometers, velocity transducers, and tachometer sensors.

- Monitoring Software:

- VibroSight®: The PC-based software used for comprehensive configuration, data visualization (waveforms, trends, spectra), alarm management, and diagnostic analysis of the entire VM600 system.

The MPC4, in conjunction with its I/O card and other VM600 modules, forms a complete and powerful system for safeguarding critical industrial assets.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922