الوصف

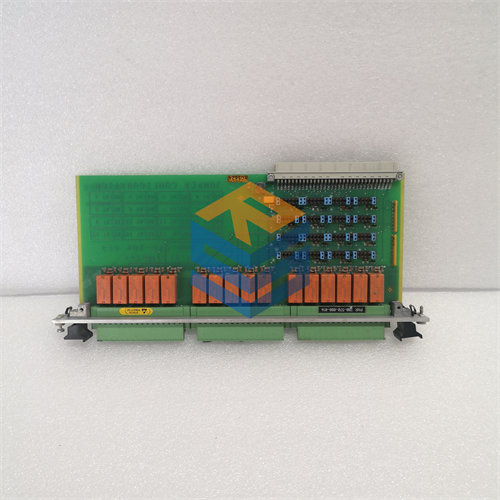

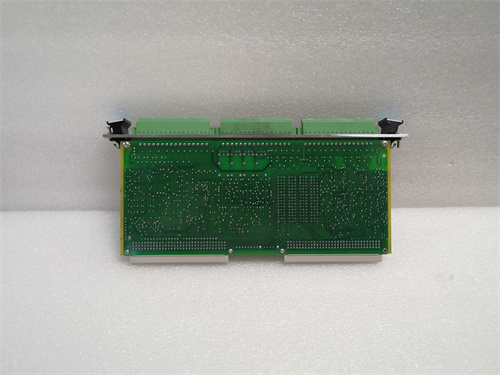

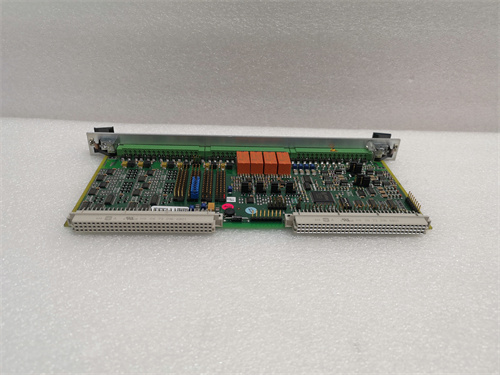

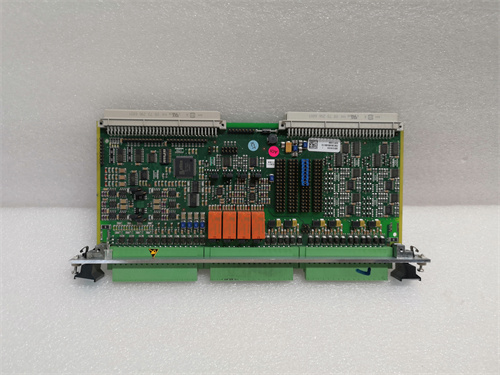

Product Name

VIBRO-METER VM-600 IOC4T

Product Description

The VIBRO-METER VM-600 IOC4T is a state-of-the-art monitoring and control device designed for vibration analysis and condition monitoring in various industrial applications. This high-performance product is built to ensure optimal machine reliability by providing accurate and timely data regarding the operational status of rotating equipment. The VIBRO-METER VM-600 IOC4T combines advanced technology with user-friendly interfaces to cater to both novice and experienced users alike.

Product Parameters

- VIBRO-METER+VM-600 IOC4T

- Input Channels: 4

- Measurement Range: ±30 g

- Frequency Range: 0.5 – 50 kHz

- Output Signal: 4-20 mA or digital communication

- Temperature Range: -40°C to +85°C

- Power Supply: 24 V DC

- Dimensions: Compact size for easy integration

Advantages and Features

The VIBRO-METER VM-600 IOC4T stands out due to its robust construction and variety of features, including:

- Real-time Monitoring: Continuous analysis of vibration levels enables proactive maintenance.

- High Sensitivity: Accurately detects even minute changes in vibration, allowing for early fault detection.

- Multipoint Measurement: With four input channels, the device can monitor multiple machines simultaneously.

- Remote Access: Supports digital communication for real-time monitoring from a remote location.

- User-Friendly Interface: Simplified data visualization for ease of interpretation and reporting.

Application Fields

The VIBRO-METER VM-600 IOC4T has diverse applications across various sectors, including:

- Oil and Gas: Monitoring performance in extraction and refining processes.

- Manufacturing: Ensuring machinery operates at peak efficiency in assembly lines.

- Power Generation: Condition monitoring of turbines and generators to prevent downtime.

- Transportation: Vibration analysis in rail and road vehicle systems.

Application Cases

In a recent case, a petrochemical company implemented the VIBRO-METER VM-600 IOC4T to monitor the vibration levels of their compressors. By utilizing this advanced technology, they detected abnormal vibration patterns early, which led to timely maintenance actions. This not only saved costs associated with unexpected downtime but also extended the lifespan of their equipment.

Competitive Analysis

When compared to competitors, the VIBRO-METER VM-600 IOC4T offers superior accuracy and real-time monitoring capabilities. While other devices may offer similar functionalities, the VIBRO-METER VM-600 IOC4T is especially noted for its reliability and ease of integration into existing systems.

Selection Advice

When considering the VIBRO-METER VM-600 IOC4T, it’s crucial to evaluate your specific monitoring needs, including:

- The type and number of machines to be monitored.

- Required connectivity options for data transmission.

- Environmental conditions where the device will be used.

Ensure you choose a model that matches your operational requirements to maximize efficiency and reliability.

Precautions

While installing the VIBRO-METER VM-600 IOC4T, ensure that:

- The device is protected from extreme weather conditions if used outdoors.

- Proper calibration is carried out to maintain measurement accuracy.

- Regular maintenance checks are conducted to guarantee long-term performance.

We are your trusted partner, providing not only the VIBRO-METER VM-600 IOC4T but also other automation spare parts, along with sales and technical support. We offer special discount prices tailored for you. Please contact us, and we will be dedicated to serving you.

VIBRO-METER+VM-600 IOC4T

| IB806 ABB PLC |

| ABB TK801V012 PLC |

| 3BSC950089R3 ABB |

| ABB SD833 3BSC610066R1 PLC |

| 3BSC610066R1 ABB DCS |

| SD833 DCS |

| TB807 3BSE008538R1 ABB PLC |

| ABB 3BSE008538R1 |

| TB80Z ABB PLC |

| TB805 3BSE008534R1 DCS |

| 3BSE008534R1 PLC |

| IB805 PLC |

| TK801V006 ABB |

| 3BSC950089R2 ABB |

| ABB SS832 3BSC610068R1 PLCDCS |

| 3BSC610068R1 ABB |

| ABB SS832 |

| CI830 3BSE021480R1 PLC |

| 3BSE021480R1 ABB CPUPLC |

| CI830 ABB I/O |

| AI835A 3BSE051306R1 ABB CPU |

| ABB 3BSE051306R1 |

| AI835A ABB |

| A0810V2 PLC |

| ABB 3BSE038415R1 PLC |

| TK811V015 ABB DCS |

| ABB 3BSC950107R1 DCS |

| SD831 3BSC610064R1 ABB DCS |

| 3BSC610064R1 ABB PLC |

| ABB SD831 PLC |

| SD832 3BSC610065R1 ABB |

| ABB 3BSC610065R1 PLC |

| SD832 ABB PLC |

| D0820 3BSE008514R1 ABB |

| ABB 3BSE008514R1 PLC |

| DO820 PLC |

| A0801 3BSE020514R1 PLCI/O |

| 3BSE020514R1 PLC |

| A0801 ABB PLC |

| AI801 3BSE020512R1 PLC |

| 3BSE020512R1 ABB PLC |

| AI801 ABB PLC |

| ABB D0802 3BSE022364R1 PLC |

| 3BSE022364R1 PLC |

| ABB D0802 PLC |

| D0801 3BSE020510R1 ABB PLC |

| 3BSE020510R1 CPU |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922