الوصف

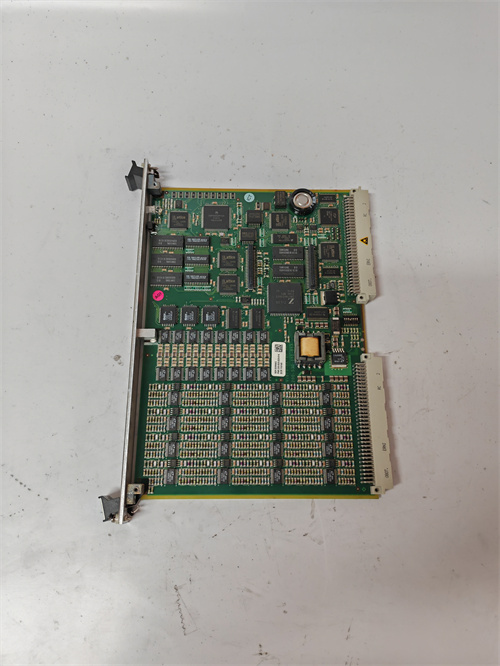

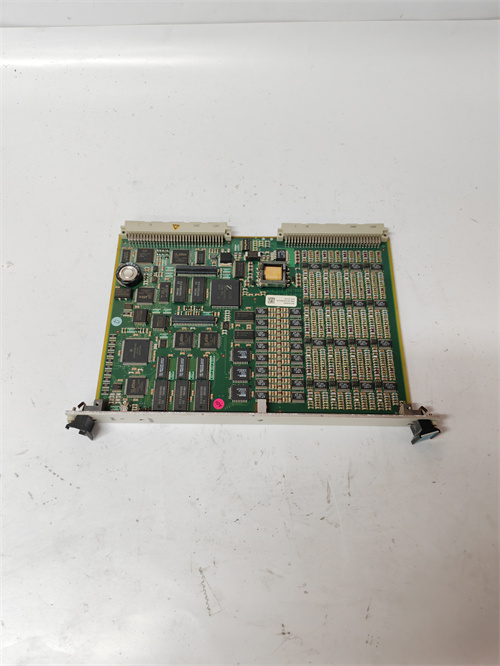

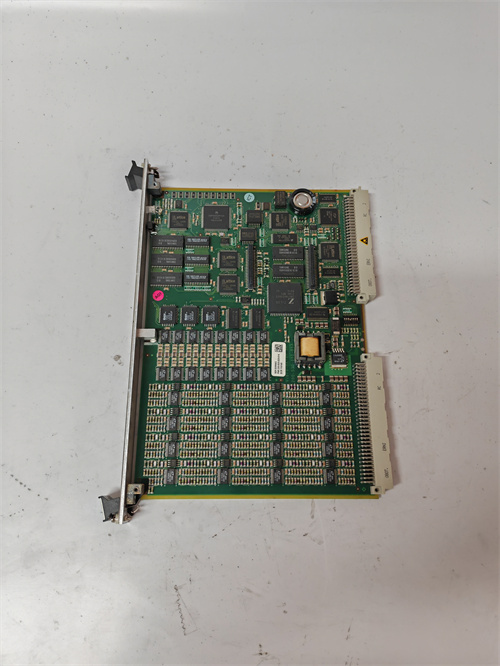

The VIBRO-METER VM600 RLC16 is a crucial optional relay card designed for use within the VM600 series of machinery protection and condition monitoring systems. Its primary function is to provide additional relay outputs when the standard relays on the main input/output (I/O) cards (like the IOC4T, IOC8T, or IOC16T) are insufficient for the application’s needs.

VIBRO-METER VM600 RLC16: Expanding Alarm and Control Capabilities

The RLC16 is essential for applications requiring a greater number of physical relay contacts to signal alarms, initiate shutdowns, or interface with external control systems (e.g., DCS, PLC, or emergency shutdown systems).

Primary Function and Role:

The VM600 RLC16 acts as an alarm output expansion module. It contains 16 independent relays that can be triggered by alarm signals generated by the VM600 system’s processing cards (such as the MPC4 for protection or AMC8 for auxiliary monitoring). This allows for a more granular and extensive range of actions based on machine conditions.

Key Features and Capabilities:

- 16 Independent Relays: The RLC16 provides 16 single-pole double-throw (SPDT) relays, meaning each relay has one common (COM), one normally open (NO), and one normally closed (NC) contact. This offers flexibility in wiring for various control schemes.

- Configurable Relay State: Each of the 16 relays can be independently configured via jumpers on the card to be either Normally Energized (NE) or Normally De-Energized (NDE).

- Normally Energized (NE): The relay coil is continuously energized during normal operation. If an alarm occurs or power is lost, the relay de-energizes, opening the normally closed contact or closing the normally open contact. This “fail-safe” mode is often preferred for critical shutdown functions.

- Normally De-Energized (NDE): The relay coil is de-energized during normal operation and energizes only when an alarm occurs.

- Software Control: The relays are controlled by open-collector drivers under software control. This means the VM600 processing cards (e.g., MPC4) send signals to the RLC16 to activate or deactivate specific relays based on configured alarm levels (e.g., Alert, Danger, Sensor OK status).

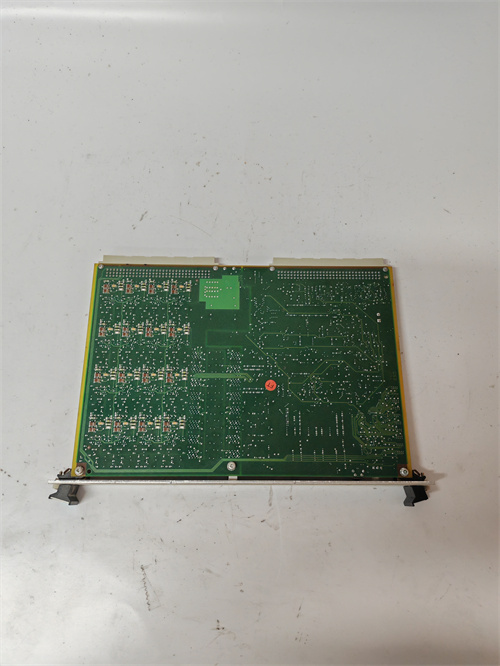

- Screw-Terminal Connections: All relay contacts (COM, NO, NC) are conveniently available on screw-terminal connectors at the rear of the VM600 rack, facilitating easy and secure wiring to external systems.

- Robust Relay Characteristics:

- Rated Voltage: Typically 250 VAC.

- Current Rating: Typically 5 AAC.

- Maximum Breaking Capacity: Around 1250 VA (without contact protection).

- Mechanical Life: High mechanical life (e.g., 15 x 10^6 operations) and electrical life (e.g., > 10^5 operations) ensure long-term reliability.

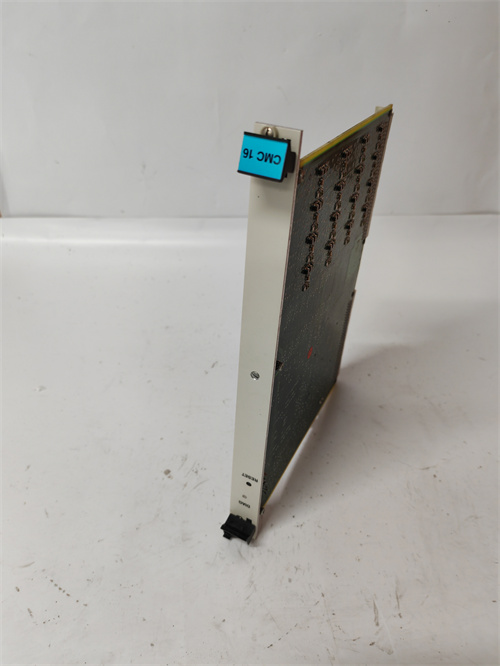

- Live Insertion/Removal: The RLC16 card supports live insertion and removal (hot-swappable) from the VM600 rack, minimizing downtime during maintenance or module replacement.

System Integration:

The VM600 RLC16 is installed in the rear card cage of a VM600 rack (ABE04x or ABE056). It connects directly to the rack’s backplane, receiving power and control signals from the rack’s internal buses.

- Driven by Processing Cards: The relays on the RLC16 are driven by alarm signals from monitoring and protection cards such as the VM600 MPC4 (Machinery Protection Card) or the VM600 AMC8 (Auxiliary Monitoring Card). These processing cards generate the actual alarm conditions, and then send commands via the internal VM600 bus (often the Open Collector bus) to the RLC16 to activate the corresponding relays.

- Expansion Function: It serves as an expansion unit for the limited number of relays (typically 4) available on the standard I/O cards (like IOC4T, IOC8T).

- No Direct Sensor Input: The RLC16 itself does not accept sensor inputs; it solely provides output relays.

Typical Applications:

The RLC16 is used in various applications where multiple discrete outputs are required to signal machine conditions or integrate with plant-wide control systems.

- Multi-Level Alarming: Providing separate relays for “Alert” and “Danger” conditions for different measurement points, allowing for tiered responses.

- Complex Shutdown Logic: Initiating various levels of machine shutdown (e.g., non-critical trip, emergency trip) based on multiple machine parameters.

- Annunciator Panels: Driving lamps or horns on annunciator panels to visually and audibly alert operators to specific machinery events.

- DCS/PLC Interface: Sending discrete alarm or status signals to a Distributed Control System (DCS) or Programmable Logic Controller (PLC) for further processing, logging, or automated control actions.

- Auxiliary Controls: Activating auxiliary equipment (e.g., standby pumps, cooling systems) based on machine health parameters.

- Event Logging and Data Archiving: Triggering external systems to log detailed data when specific alarm conditions are met.

Product Status:

The VIBRO-METER VM600 RLC16 is part of the mature VM600 product line. While it is still supported by Parker Meggitt for existing installations, including the provision of spares and repair services, for new projects, it has been largely superseded by the VM600Mk2 RLC16Mk2 module. The Mk2 version offers updated technology and potentially enhanced features within the newer generation of the VM600 system. However, the original RLC16 remains fully functional and supported for its existing user base.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922