الوصف

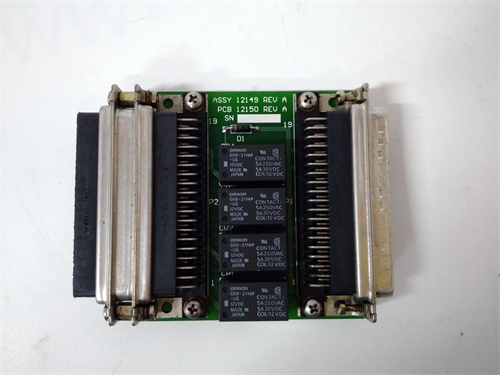

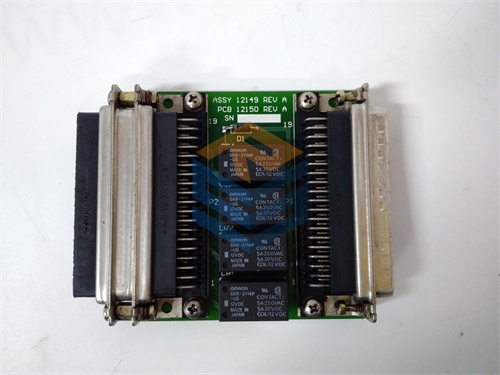

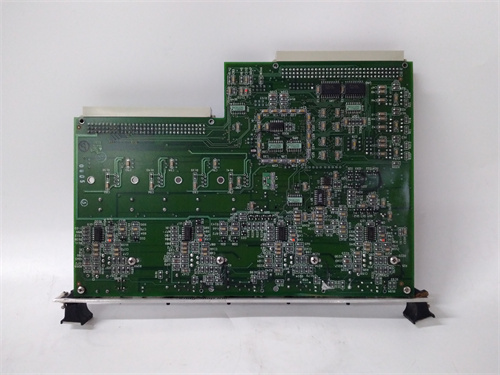

VMIC+ASSY 11994R13 ASSY 12149 are advanced industrial interface modules developed by VMIC, a leader in providing reliable automation and communication solutions for industrial environments. These modules are engineered to enhance connectivity and data processing in complex industrial control systems.

Product Name

VMIC+ASSY 11994R13 ASSY 12149 Interface Modules

Product Description

VMIC+ASSY 11994R13 ASSY 12149 are a pair of complementary modules designed to facilitate seamless data exchange and control signal management in industrial automation setups. ASSY 11994R13 focuses on high-speed data transmission between PLCs and peripheral devices, while ASSY 12149 specializes in signal conditioning and isolation, ensuring that sensitive control signals remain unaffected by electrical noise and interference. Together, VMIC+ASSY 11994R13 ASSY 12149 form a robust communication backbone that supports real-time operation in demanding industrial settings.

These modules are built to integrate with a wide range of industrial equipment, making VMIC+ASSY 11994R13 ASSY 12149 suitable for both new installations and retrofits of existing systems. VMIC+ASSY 11994R13 ASSY 12149 feature ruggedized enclosures that protect internal components from dust, vibration, and extreme temperatures, ensuring long-term reliability. The design of VMIC+ASSY 11994R13 ASSY 12149 also incorporates advanced signal processing algorithms that minimize latency, a critical factor for time-sensitive applications such as motion control and process regulation. Additionally, VMIC+ASSY 11994R13 ASSY 12149 support hot-swapping, allowing for module replacement without shutting down the entire system, which significantly reduces downtime during maintenance.

Product Parameters

- Power Supply (ASSY 11994R13): DC 24V ±10%

- Power Supply (ASSY 12149): DC 12V ±10%

- Power Consumption (ASSY 11994R13): Maximum 12W

- Power Consumption (ASSY 12149): Maximum 8W

- Dimensions (ASSY 11994R13): 180mm x 110mm x 50mm

- Dimensions (ASSY 12149): 150mm x 90mm x 45mm

- Weight (ASSY 11994R13): Approximately 0.4kg

- Weight (ASSY 12149): Approximately 0.3kg

- Operating Temperature Range (Both Modules): -40°C to +75°C

- Storage Temperature Range (Both Modules): -55°C to +85°C

- Communication Interfaces (ASSY 11994R13): 2 x Gigabit Ethernet ports, 1 x CANbus port

- Signal Inputs/Outputs (ASSY 12149): 16 analog inputs, 8 analog outputs, 32 digital I/O

- Data Transfer Rate (ASSY 11994R13): Up to 1Gbps (Ethernet), 1Mbps (CANbus)

- Isolation Voltage (ASSY 12149): 2500V DC between signal and power lines

- MTBF (Mean Time Between Failures, Both Modules): Over 250,000 hours

- Protection Rating (Both Modules): IP20 (for cabinet mounting)

- Vibration Resistance (Both Modules): 10-500Hz, 20g peak acceleration

- Shock Resistance (Both Modules): 50g peak acceleration for 11ms

Advantages and Features

VMIC+ASSY 11994R13 ASSY 12149 offer several key advantages that set them apart in industrial automation. First, their wide operating temperature range (-40°C to +75°C) and robust construction make them ideal for harsh environments like oil refineries, mining operations, and steel mills, where extreme conditions often challenge standard equipment. Second, the high data transfer rate of ASSY 11994R13 (up to 1Gbps) ensures that large volumes of data are transmitted with minimal delay, critical for real-time control systems.

Another major benefit is the advanced signal isolation in ASSY 12149 (2500V DC), which prevents electrical noise from distorting signals—this is especially valuable in facilities with heavy machinery that generates electromagnetic interference. VMIC+ASSY 11994R13 ASSY 12149 also excel in scalability: their modular design allows for easy integration with additional I/O modules or communication interfaces as system needs grow. User-friendly configuration software simplifies setup, while built-in diagnostic tools provide real-time alerts for issues like connection failures or signal degradation, reducing troubleshooting time. Additionally, both modules have low power consumption, contributing to energy efficiency in industrial operations.

Application Areas and Case Studies

VMIC+ASSY 11994R13 ASSY 12149 are widely used across industries. In the energy sector, they’re deployed in power plants to connect turbine control systems with SCADA (Supervisory Control and Data Acquisition) networks. For example, a coal-fired power plant integrated VMIC+ASSY 11994R13 ASSY 12149 to link temperature and pressure sensors (via ASSY 12149’s analog inputs) to a central PLC, using ASSY 11994R13 for high-speed data transmission to the SCADA system. This setup improved turbine performance monitoring, reducing unplanned downtime by 30%.

In manufacturing, these modules support precision processes. A automotive parts manufacturer used VMIC+ASSY 11994R13 ASSY 12149 to control robotic welding arms: ASSY 12149 conditioned sensor signals to ensure accurate weld positioning, while ASSY 11994R13 transmitted real-time feedback to the PLC. This reduced weld defects by 25% and increased production throughput. In mining, they connect conveyor belt sensors to control systems, enabling remote monitoring of belt tension and speed— a gold mine reported a 20% decrease in maintenance costs after implementing VMIC+ASSY 11994R13 ASSY 12149.

Competitor Comparison

Compared to similar modules from competitors like Siemens and Schneider Electric, VMIC+ASSY 11994R13 ASSY 12149 offer superior temperature tolerance (+75°C vs. the typical +60°C of competitors), making them more reliable in extreme heat. ASSY 11994R13’s Gigabit Ethernet support outperforms many competitors’ 100Mbps interfaces, enabling faster data transfer for large-scale systems. ASSY 12149 also provides higher signal isolation (2500V DC) than most alternatives (1500-2000V DC), offering better protection against electrical noise.

In terms of cost-effectiveness, VMIC+ASSY 11994R13 ASSY 12149 deliver more I/O channels and faster communication at a competitive price point. VMIC’s comprehensive technical support, including 24/7 troubleshooting and detailed documentation, also gives them an edge over brands with slower response times.

Selection Recommendations

When choosing VMIC+ASSY 11994R13 ASSY 12149, start by assessing your system’s needs: determine the number of analog/digital signals (to confirm ASSY 12149’s I/O capacity) and the required data transfer speed (to leverage ASSY 11994R13’s Gigabit Ethernet). If your application involves extreme temperatures or vibration (e.g., outdoor pipelines), verify that the modules’ environmental ratings match your conditions.

Check compatibility with existing equipment: ensure ASSY 11994R13 works with your PLC’s communication protocols (e.g., Ethernet/IP) and that ASSY 12149’s signal ranges match your sensors (e.g., 4-20mA for analog inputs). For future scalability, select modules with extra I/O channels or Ethernet ports to accommodate system expansions. Consulting VMIC’s technical team or our experts can help validate compatibility and optimize your setup.

Precautions

When installing and operating VMIC+ASSY 11994R13 ASSY 12149, follow these guidelines: Always power off the system before wiring to prevent electrical damage. Use shielded cables for signal lines to enhance noise immunity, especially in high-interference environments. Ensure all connections are tight to avoid intermittent signal loss.

Regular maintenance includes inspecting for dust buildup (which can cause overheating) and checking for loose connections during scheduled shutdowns. Avoid exposing the modules to direct moisture or corrosive gases, even though they’re ruggedized. Only trained technicians should perform firmware updates, using VMIC’s official software to avoid compatibility issues. Keep a copy of the user manual on-site for reference during troubleshooting.

We are your trustworthy partner. We provide sales and technical support for VMIC+ASSY 11994R13 ASSY 12149 and other automation spare parts. We offer you special discount prices. Please contact us, and we will serve you wholeheartedly.

VMIC+ASSY 11994R13 ASSY 12149

A-B 1768-L43A

ABB ACS550-01-045A-4+B055

GE IC693CPU350

NI PXI-6115

艾默生 HD22005-2

SCHNEIDER 140CPU65150

ABB ICSM06A6

WESTINGHOUSE 1C31197G01

OMRON NT631C-ST151B-EV2

A-B 1769-L32E

MODICON AS-B883-001

GE IC086SLM082

A-B 1756-OF8

GE IC695ALG616

METRONIX ARS-310/5UL

KISTLER 5073A111

SCHNEIDER 140CHS11000 SV:01.04

GE IC695PBM300

BENTLY 136483-01

BENTLY 9200-01-01-10-00

WESTINGHOUSE 5X00070G04

GE IC695NIU001

A-B 1784-PKTX/D

A-B 2094-BM01-S

GE IC693CMM321

ABB UNS0119A-P V101

GE IC695ALG616

GE IC755SUE1OCTD

Bently 330500-02-00

Bently 3500/25

HONEYWELL TC-OAV081

WESTINGHOUSE 1C31166G01

EMERSON 1C31169G02

HORST KNABEL C0600-039-C

HBM RNT68T

GE IC695PNS001

H0NEYWELL 05701-A-0301

CANON 81000P/R

A-B 20G11NC011JA0NNNNN

FOXBORO FPS400-24 P0922YU

ABB UGTMEM-03LBB11

GE IC693PWR331C

NI PCI-6230

ABB 6MBI450U-120A-05/AGDR-71C

NI SCXI-1163

A-B 1756-L61

A-B 5069-IF8

IMS MX-CS100-401

WATLOW ANAFAZE CLS208

ALLIED TELESIS AT-8000S/24POE

NI SCXI-1163

GE IC695CPU310-FT

SIEMENS 7ML5221-1BA17

NI SCXI-1163

REXROTH VT1516-S-11

PULNIX TM9701

NI SCXI-1163

ABB RUSB-02

GE IC670GBI102C

ABB PBSE5117

GE D20EME

ABB ICMK14F1 DC24V

Emerson 5X00062G01

A-B 25C-D017N114

SCHNEIDER 140NOC78000

GE IC693BEM341

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922