الوصف

The Woodward 8235-400 is a specific part number for a Flo-Tech™ Integrated Throttle Body (ITB) and Actuator. This means it’s an all-in-one unit designed to precisely control air or fuel flow to an engine.

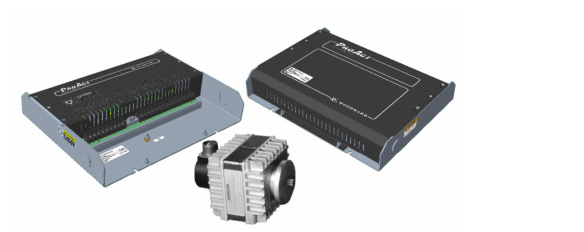

WOODWARD 8235-400: Flo-Tech™ Integrated Throttle Body (ITB) and Actuator

The Woodward 8235-400 is a highly integrated component that combines an electric actuator and a throttle body into a single, compact unit. It’s part of the Flo-Tech™ family, engineered for precise flow control in engine applications.

Product Overview

- Product Type: Integrated Throttle Body (ITB) and Electric Actuator

- Manufacturer: Woodward

- Series: Flo-Tech™ ITB

- Function: Electronically controls the flow of air or fuel (gaseous media) to a prime mover (engine) by precisely adjusting the throttle plate position. This enables accurate speed control, air/fuel ratio management, and emissions compliance.

- Key Feature: Flo-Tech ITBs are designed with flow shaping to enhance engine idle stability. They can provide equivalent maximum flow rates to standard butterfly throttle bodies of the same diameter, but with integrated electronic control.

- Safety: The system contains a return spring to ensure it returns to a fail-safe position (e.g., minimum fuel or air) upon loss of power or signal, complying with safety specifications like DOT 571.124.

- Input Options: Flo-Tech ITBs are versatile and typically accept various command input options, such as PWM (Pulse Width Modulation), 0–5 Vdc, 4–20 mA, and 0–200 mA.

- Power Supply: Requires a DC power supply, often in the range of 9–32 Vdc (12/24 Vdc nominal). The supply must be capable of providing a sustained 25 watts at steady-state and 50 watts for transient conditions (for at least 0.25 seconds).

Detailed Description

Woodward’s Flo-Tech ITBs, including the 8235-400, offer a modern and integrated solution for controlling engine air or gaseous fuel flow. By combining the actuator and throttle body, they simplify installation and provide a highly responsive and accurate control element.

Key characteristics of the 8235-400:

- Integrated Design: This unit consolidates the electric actuator and the throttle body, streamlining installation and reducing complexity compared to separate components with mechanical linkages. This saves space and reduces potential points of failure.

- Precise Flow Control: The throttle plate’s position is accurately controlled in proportion to the command signal it receives. This allows for very precise modulation of air or fuel flow, which is crucial for meeting dynamic engine control demands and optimizing performance.

- Flow Shaping: A distinctive design feature of the Flo-Tech family, this helps to optimize flow characteristics, significantly improving engine idle stability through refined control at very low flow rates.

- Versatile Inputs: With support for multiple standard industrial input signals, it can seamlessly integrate with diverse electronic control modules (ECMs) and system architectures, offering flexibility in control system design.

- Position Feedback: The unit typically provides a position feedback signal (ranging from 0.5 V to 4.5 Vdc) that accurately indicates the actual throttle plate position. This allows the main engine controller to continuously monitor and verify the actuator’s operation, enabling closed-loop control and diagnostics.

- Robust Construction: Engineered for durability in harsh industrial and engine environments, it’s built to withstand vibrations, extreme operating temperatures (typically -40 to +105 °C), and environmental exposure.

- Throttle Body Size: While the specific bore size for the 8235-400 isn’t always individually detailed in general overviews, the Flo-Tech ITB family is available in various common bore sizes (e.g., 33 mm, 48 mm, 60 mm, 68 mm, and 75 mm). The “-400” suffix denotes a particular configuration or bore size within this series.

Applications

The Woodward 8235-400 is widely used in engines where precise control of air or gaseous fuel flow is critical for performance, efficiency, and emissions:

- Gaseous Fuel Engines: Particularly for engines running on natural gas, CNG, LNG, or biogas, where precise air/fuel ratio control is essential for optimal combustion and meeting stringent emission standards.

- Emissions Control Systems: It serves as a key component in systems designed to achieve and maintain compliance with various exhaust emission regulations.

- Industrial Power Generation: Employed in engine-driven generator sets to precisely control load response and maintain stable electrical frequency, which is vital for grid stability.

- Engine Bench Testing: Utilized in development and testing environments where highly repeatable and accurate control of air/fuel intake is required for research and validation.

- Modernization Projects: It’s an ideal choice for directly replacing older, manual throttle bodies, upgrading existing systems to electronic control without requiring extensive redesign of mechanical linkages or separate actuator mounting.

Related Products/Series

The 8235-series belongs to Woodward’s broader Flo-Tech and ProAct families of actuators and integrated control devices. Other related part numbers in the Flo-Tech ITB family might include:

- 8235-xxx (other Flo-Tech ITBs): This family includes various models with different bore sizes and specific features, such as 8235-147, 8235-185, 8235-248, 8235-249, 8235-398, 8235-399, 8235-402, and 8235-406.

- ProAct Controllers: While the 8235-400 has an integrated actuator, it still requires a higher-level electronic control module (such as a ProAct Speed Control or an Air/Fuel Ratio Control) to send the command signals that dictate its position.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922