الوصف

The Woodward 8300-716 is a specific part number that identifies a component within the ProAct™ Gen 1 (Generation 1) series, primarily related to an actuator/driver system or a ProAct Positioner.

WOODWARD 8300-716: ProAct™ Gen 1 Positioner or Actuator/Driver System (Older Generation)

The Woodward 8300-716 refers to a component or system from Woodward’s earlier ProAct™ Generation 1 product line. It’s often associated with a ProAct Positioner (16 pin) or represents an integrated actuator/driver system from that generation.

Product Overview

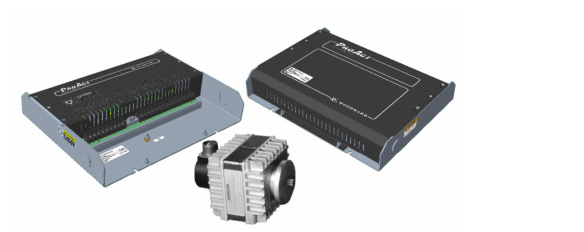

- Product Type: Digital Positioner or Integrated Actuator/Driver System

- Manufacturer: Woodward

- Series: ProAct™ Gen 1

- Function: In the context of a “Positioner,” it would precisely control the position of an actuator’s output shaft based on an input command. If it refers to an “Actuator/Driver System,” it’s a complete functional unit designed for the precise control of prime movers (engines or turbines) by adjusting fuel or air flow.

- Key Feature: It belongs to the “Gen 1” of ProAct systems, which signifies an older generation of technology.

- Compatibility Note: A critical piece of information regarding Gen 1 ProAct systems is that old actuators and drivers (like those within the 8300-716 system) are not interchangeable with the new actuators and drivers (e.g., ProAct Model II or III). If replacement is needed, both the actuator and driver typically must be replaced at the same time to ensure compatibility.

- Documentation: Associated with Woodward documentation such as Product Spec 03434 and Manuals 26729, B26845.

Detailed Description

The ProAct systems from Woodward are known for their digital precision in controlling prime mover speed, load, or position. The 8300-716 represents an earlier iteration of this technology.

Key characteristics and implications of the 8300-716 system:

- Positioner Functionality: If 8300-716 specifically denotes a “ProAct Positioner,” it means the module takes an external command signal (e.g., 4-20mA, voltage, or PWM) and precisely positions a connected ProAct actuator. This allows for very accurate control of the actuator’s output shaft, which then manipulates engine fuel or air.

- Integrated Actuator/Driver Context: In some older Woodward terminology, a single part number like this might have encompassed a matched actuator and its specific driver module. This means the driver portion (the electronics that receive commands and power the actuator) and the actuator (the electromechanical device that moves) were designed as a tightly integrated pair.

- Gen 1 Technology: This designation indicates it’s from the first generation of ProAct systems. While effective in its time, these older systems have been superseded by newer, more advanced, and often more modular ProAct generations (like Model II, III, and IV).

- Non-Interchangeability: The explicit warning about non-interchangeability with newer components is extremely important. This means you cannot simply swap out one piece of an 8300-716 system (e.g., just the actuator or just the driver) with a modern equivalent; the entire system in that control loop likely needs to be upgraded or replaced with a compatible modern ProAct solution.

- Robust Design: Like all Woodward products, Gen 1 ProAct components were built for rugged industrial environments, designed to withstand vibrations, temperature extremes, and electromagnetic interference.

Applications

Given its role in prime mover control, the Woodward 8300-716 system would have been used in:

- Power Generation: For precise control of engine-driven or turbine-driven generator sets, ensuring stable electrical frequency and efficient power delivery.

- Industrial Engines: On various industrial diesel or gaseous engines powering pumps, compressors, fans, or other machinery where accurate and responsive control of speed, load, or position was required.

- Marine Applications: In some older marine engine control systems.

Replacement Considerations

If you encounter a Woodward 8300-716 system and require maintenance, repair, or replacement, it’s crucial to:

- Verify the Exact System Configuration: Determine if the 8300-716 refers to just a positioner module or a complete actuator/driver combination in your specific installation.

- Consult Current Woodward Resources: Due to the “Gen 1” nature, always refer to the latest Woodward product bulletins, service manuals, or contact Woodward technical support directly. They can provide the most accurate information on current replacement options and compatibility.

- Plan for System Upgrades: Be prepared for the possibility that a direct, one-for-one replacement might not be available, and you may need to upgrade to a newer ProAct system that includes both a compatible modern driver (e.g., from the 8400-series) and a compatible actuator (e.g., from the 8256-series). This often improves performance and reliability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922