الوصف

The WOODWARD 9907-1199 is not a traditional mechanical actuator. Instead, it is a CPC-II Current-to-Pressure Converter with specific features that tailor it for precise industrial control.

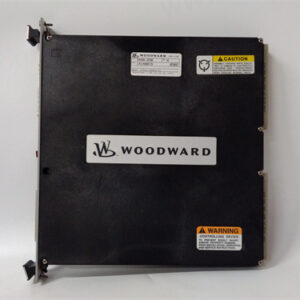

WOODWARD 9907-1199: CPC-II Current-to-Pressure Converter

The WOODWARD 9907-1199 is an electrohydraulic pressure-regulating valve control, engineered to convert electrical signals into precise hydraulic pressure. This function is vital for accurately positioning single-acting steam turbine governor valves.

Product Overview

This part number designates a specific configuration within Woodward’s advanced CPC-II (Current-to-Pressure Converter, Generation II) series. CPC-II units are known for their exceptional accuracy, high resolution, and robust design, making them ideal for challenging industrial environments.

- Product Type: Current-to-Pressure Converter / Electrohydraulic Pressure-Regulating Valve Control

- Manufacturer: Woodward

- Part Number: 9907-1199

- Model Designation: CPC-II

- Function: It accepts a standard 4–20 mA pressure demand signal from an electronic control system (like a turbine controller or Distributed Control System – DCS) and precisely regulates hydraulic oil pressure. This controlled pressure is then used to position single-acting steam turbine governor valves.

- Output Pressure Range: Typically 0 to 25 bar (0 to 363 psi).

- Design Specifics: This model is built for single-acting operation, meaning it controls the pressure to move a valve in one direction, while a spring provides the return force. It also includes specific hazardous location ratings.

Detailed Product Description

The Woodward 9907-1199 CPC-II is designed for high performance and reliability in demanding industrial applications, particularly those involving steam turbines. Key features and characteristics include:

- Precise Pressure Control: The unit incorporates a highly accurate internal pressure sensor and a PID (Proportional-Integral-Derivative) controller. This combination ensures precise and stable control over the output oil pressure, which directly translates to accurate positioning of the turbine valve.

- “Dirt Buster” Technology: A significant feature of the CPC-II is its robust design, often referred to as “Dirt Buster” or “Silt Buster” technology. It includes a strong actuator, corrosion-resistant materials, a unique single-moving rotary valve, and a self-cleaning port design. This makes it highly resistant to dirty or contaminated oil (capable of handling up to ISO20/16 cleanliness), which is a common reliability issue in industrial hydraulic systems. This technology helps prevent silt buildup without interrupting operation.

- Enhanced Dynamics: The CPC-II features enhanced dynamics, meaning it’s designed for rapid and stable response to changes in control signals, which is crucial for effective turbine speed and load control.

- Redundancy Capabilities: The unit can be configured to accept redundant pressure demand inputs from one or two (redundant) controllers and can also receive signals from internal and external redundant oil pressure sensors. This significantly enhances system reliability in critical applications by allowing for redundant master/slave configurations or dual-redundant CPC setups.

- Fail-Safe Mechanism: In the event of an internal unit failure, loss of electrical input power, pressure sensor failure, or processor failure, an internal valve-return-spring forces the CPC to a failsafe position, typically ensuring the safe closure of turbine control valves.

- Manual Stroke Function: It includes a manual stroke screw, allowing for local manual adjustment of the output pressure (and thus turbine valve position) for maintenance or emergency situations. It can also be controlled remotely or locally via a PC-based service tool.

- Diagnostic Features: The CPC-II provides status indications for pressure sensor health, input demand signal health, internal unit health, and input power quality, allowing operators to monitor its operating status effectively.

- Certifications: As a product designed for industrial environments, it carries relevant certifications for hazardous area classifications (e.g., ATEX, IECEx, CSA, Zone 2).

Technical Specifications

Typical Applications

The WOODWARD 9907-1199 CPC-II Current-to-Pressure Converter is primarily used in industrial fields that demand precise and stable control of steam valves, playing a vital role in:

- Steam Turbine Valve Control: Its core application is to accurately position the control valves of single-acting steam turbines, which in turn regulates steam flow, affecting turbine speed and power output.

- Turbine Speed and Load Control: By providing precise control over steam admission, it directly contributes to the stable control of turbine speed and the efficient management of electrical load in power generation.

- Power Generation Plants: Integrated into the control systems of steam power plants.

- Petroleum and Chemical Industries: Used in processes that rely on steam turbines for power or compression.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922