الوصف

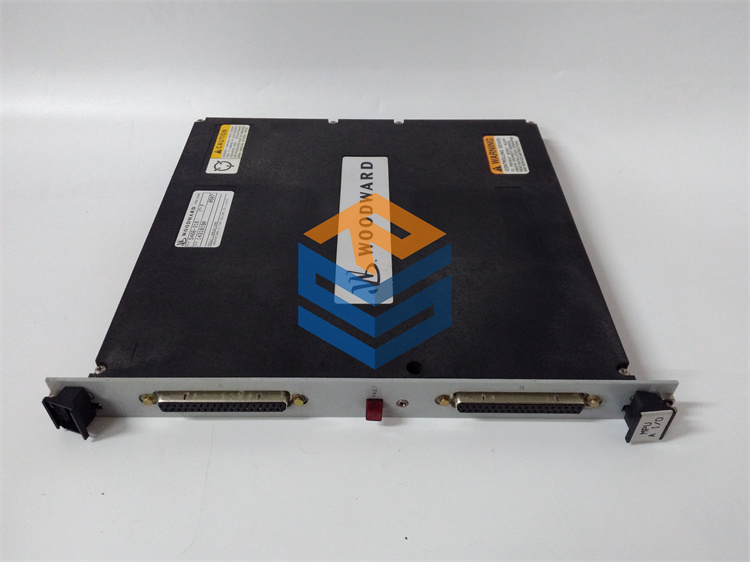

Product Name: WOODWARD 5466-316 PLC Module

Product Description:

The WOODWARD 5466-316 is a high-performance Programmable Logic Controller (PLC) module used for control and automation in industrial and power generation systems. It is part of Woodward’s family of robust and reliable control solutions, designed to meet the demanding requirements of complex processes, especially in the energy, power, and oil & gas sectors.

Woodward’s 5466-316 PLC module provides real-time control, data acquisition, and high-speed communication, ensuring reliable operation in critical systems. This module is widely used for controlling turbines, engines, compressors, generators, and other industrial machinery. It ensures precise and fault-tolerant operations through its advanced diagnostics, fault detection, and communication capabilities.

This PLC is equipped with versatile I/O capabilities, supporting both digital and analog inputs/outputs, and offers high-speed processing suitable for a variety of automated control applications.

Product Parameters:

- Manufacturer: Woodward Inc.

- Model: 5466-316

- Module Type: Programmable Logic Controller (PLC)

- I/O Capabilities: Analog and Digital I/O

- Operating Voltage: Typically 24V DC (nominal)

- Operating Temperature Range: -40°C to 70°C

- Mounting Type: DIN Rail Mount for standard industrial enclosures

- Weight: Approx. 500g to 800g (depending on configuration)

Specifications:

-

General Specifications:

- Module Type: A high-performance PLC for industrial automation and control applications, with specialized features for power generation and process control.

- Input Voltage: 24V DC (nominal), with wide tolerance for industrial environments.

- Power Consumption: Approximately <10W (depending on the configuration and load).

- Mounting: DIN Rail for easy installation inside control cabinets.

- Dimensions: Typically 180mm x 120mm x 60mm (subject to specific configuration).

- Weight: Approx. 500g to 800g depending on specific setup.

-

Processor & Performance:

- Processor Type: High-performance microprocessor with real-time processing capabilities.

- Processing Speed: Capable of handling high-speed control loops and large amounts of data in real time.

- Control Loops: Supports high-speed PID control loops with rapid updates for critical system control.

- Data Processing: Real-time data acquisition and processing with minimal latency for high-reliability applications.

-

I/O & Connectivity:

- Digital I/O: Multiple digital input and output channels for monitoring and controlling devices like sensors, actuators, and relays.

- Analog I/O: Provides several channels for analog input and output, essential for interfacing with pressure, temperature, and other analog sensors.

- Communication Ports:

- Ethernet/IP (optional): For communication with remote monitoring systems and other PLCs.

- Modbus RTU / TCP: Commonly used industrial communication protocols for integrating with other field devices and control systems.

- CANbus: Optional integration for communication with other Woodward and third-party devices.

- RS-232/RS-485: For serial communication with other industrial equipment.

-

Performance & Control:

- Real-Time Data Processing: Fast and efficient handling of I/O signals with low latency for precise control.

- High-Speed Control: Supports high-speed data processing for turbine control, generator synchronization, and other critical automation tasks.

- Diagnostics & Fault Monitoring: Built-in diagnostic capabilities, providing real-time information on system health, fault conditions, and system performance, enabling fast troubleshooting.

-

Environmental and Durability Specifications:

- Operating Temperature Range: -40°C to 70°C to ensure reliable operation in harsh environments, including extreme temperatures.

- Storage Temperature Range: -40°C to 85°C for safe storage.

- Relative Humidity: 5% to 95% (non-condensing).

- Ingress Protection: IP20 (designed for installation inside industrial control panels or enclosures).

- Vibration Resistance: Designed to withstand moderate vibrations typically found in industrial environments.

-

Compliance and Safety:

- Certifications: CE, UL, and other relevant industrial safety certifications.

- EMC Compatibility: Complies with Electromagnetic Compatibility (EMC) standards to prevent interference and ensure stable operation in high-noise environments.

- Safety Features: Built-in fault detection and diagnostics to ensure safe operation in critical industrial systems.

-

Advanced Features:

- Modular Design: The 5466-316 is a modular solution, allowing for easy expansion and adaptation to different system requirements.

- Customizable I/O Modules: Tailored for different input/output requirements, such as controlling motors, sensors, and complex machinery.

- User Interface: Configurable interface options to meet different application needs.

- Flexible Communication: The PLC supports multiple communication protocols, making it easy to integrate with different systems and devices.

Applications:

- Power Generation: The 5466-316 is widely used in turbine control, generator synchronization, and other power plant automation applications, where real-time performance and diagnostics are crucial.

- Oil & Gas: Used in compressor control, pressure regulation, and flow monitoring in oil rigs and refineries.

- Industrial Automation: Controls a wide range of machinery and processes, including pumps, conveyors, motors, and other heavy-duty equipment in industries like manufacturing, mining, and chemical processing.

- Process Control: Ideal for applications where high-speed, real-time control is needed, such as distillation, blending, or reactor monitoring in industries such as chemical, food & beverage, and pharmaceuticals.

- Marine & Off-Highway Equipment: Used in large marine engines, diesel generators, and vehicle control systems where robust, reliable control is required.

Conclusion:

The WOODWARD 5466-316 PLC module offers high performance, reliable real-time control, and flexible connectivity for industrial and process control applications. Whether used in power generation, oil & gas, manufacturing, or other complex industrial systems, this PLC provides robust diagnostics, fast processing speeds, and exceptional reliability in harsh environments. It is the ideal solution for industries that demand precision, safety, and uptime.

GE DS3800HAIC

GE DS200AAHAH1AED

GE DS200AAHAH2ADC

GE DS200ACNAG1A

GE DS200ACNAG2A

GE DS200ADCIF1ABA

GE DS200ADCIH1ADB

GE DS200ADGIH1AAA

GE DS200ADMAH1AAA

GE DS200ADMAH1AAC

GE DS200ADPAG1A

GE DS200ADPBG1A

GE DS200CDAAG1A

GE DS200CDBAG1B

GE DS200CLACG1A

GE DS200CPCAG1A

GE DS200CSSAG1B

GE DS200CTBAG1A

GE DS200CVMAG1A

GE DS200CVMAG3A

GE DS200DACAG1A

GE DS200DCFBF1AAB

GE DS200DCFBG1B

GE DS200DCFBG2B

GE DS200DCPAG1A

GE DS200DCVAG1A

GE DS200DCVAG2A

GE DS200DDTBG1A

GE DS200DDTBG2A

GE DS200DENCF1ACF

GE DS200DENCF1ACG

GE DS200DENCF1ACH

GE DS200DENCF1ADB

GE DS200DENCF1ADC

GE DS200DENCF1AEA

GE DS200DENCF1BCB

GE DS200DENCF1BDB

GE DS200DENCF1BDC

GE DS200DENCF1BDD

GE DS200DENCF1BDE

GE DS200DENCF1BDG

GE DS200DENCF2BCC

GE DS200DENQF1ACG

GE DS200DENQF1ACH

GE DS200DENQF1ADB

GE DS200DENQF1AEA

GE DS200DENQF1BCB

GE DS200DENQF1BDB

GE DS200DENQF1BDC

GE DS200DENQF1BDD

GE DS200DENQF1BDE

GE DS200DENQF1BDG

GE DS200DMCAG1A

GE DS200DMCAG2A

GE DS200DMCBF1CFA

GE DS200DMCBF1CIA

GE DS200DMCBF1CJC

GE DS200DMCBG1A

GE DS200DPCAG1A

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922