الوصف

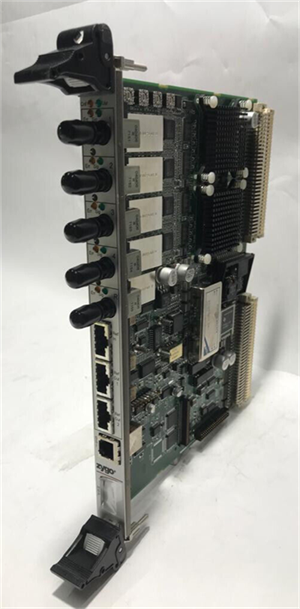

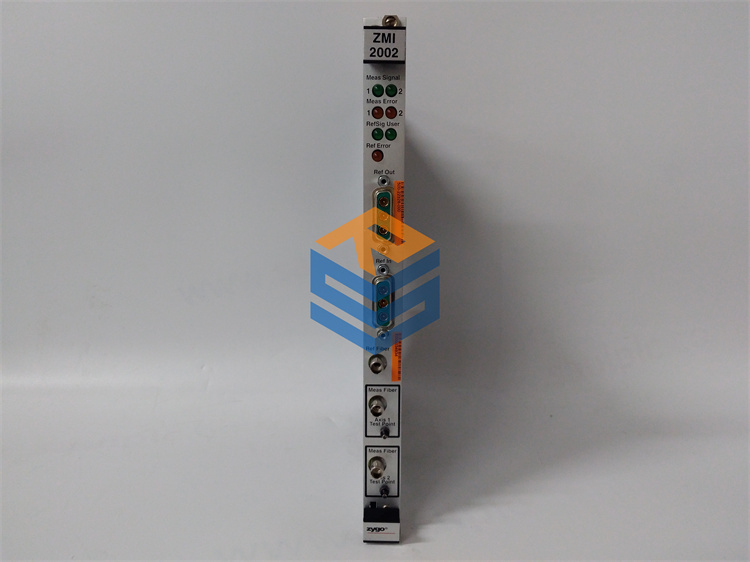

ZYGO ZMI-2002 8020-0211 PLC Module

Product Name:

- ZYGO ZMI-2002 8020-0211

Product Description:

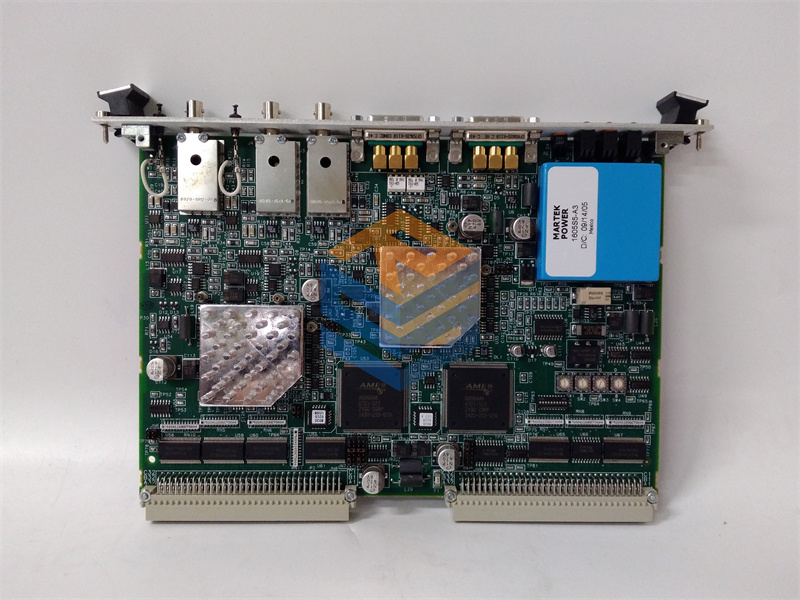

The ZYGO ZMI-2002 8020-0211 is a programmable logic controller (PLC) module designed for precision measurement and control applications, particularly in optical metrology systems. ZYGO Corporation, known for its innovations in high-precision optical systems and measurement equipment, integrates advanced PLC functionality into this module to facilitate seamless control of automated processes in applications like surface measurement, inspection, alignment, and other high-precision manufacturing processes.

This module is typically utilized in metrology systems and is suited for environments requiring high accuracy and repeatability. The ZYGO ZMI-2002 offers reliable performance in controlling and automating a variety of processes, including actuators, sensors, motors, and data collection systems, making it ideal for industries such as semiconductor manufacturing, aerospace, and optics production.

Product Parameters & Specifications:

General Information:

- Model: ZYGO ZMI-2002 8020-0211

- Category: PLC Module

- Brand: ZYGO Corporation

- Application: Precision measurement, control of optical metrology systems, automation of high-accuracy processes

- Mounting: Typically installed in control cabinets or DIN rail systems

- Power Supply: Usually supplied by a 24 VDC power source

I/O Specifications:

-

Digital Inputs:

- The ZMI-2002 supports multiple digital inputs for interfacing with external sensors or switches.

- Input types typically include 24 VDC or 24 VAC logic signals.

- The number of inputs varies based on configuration but typically includes a 16-32 digital input points range.

-

Digital Outputs:

- Supports digital output points for controlling external devices, actuators, or relays.

- 24 VDC or 24 VAC output signals are common.

- Typically features 16-32 digital output points, with sourcing or sinking capabilities.

-

Analog Inputs:

- Equipped with analog input channels for integration with sensors measuring variables like temperature, pressure, or position.

- Input types typically range from 4-20 mA or 0-10 VDC, with 12-16 channels for high-precision applications.

-

Analog Outputs:

- Provides analog output channels for controlling external devices requiring variable signals like motor speed or positioning systems.

- Output range typically includes 0-10 VDC or 4-20 mA.

-

Communication Ports:

- RS-232/RS-485 Serial Communication for connecting with external devices or controllers.

- Ethernet or Ethernet/IP support for integration with more complex control systems or other PLCs.

- Modbus RTU/TCP and OPC compatibility for communication with remote systems or third-party equipment.

Power Supply:

- Nominal Voltage: 24 VDC (common industrial standard)

- Voltage Range: 20.4 VDC to 28.8 VDC

- Power Consumption: Typically consumes around 6W to 15W depending on configuration and load.

Operating Conditions:

-

Operating Temperature:

- Typically operates within the range of 0°C to 60°C (32°F to 140°F).

- Storage temperature range: -20°C to +70°C (-4°F to 158°F).

-

Humidity:

- Operates within 5% to 95% non-condensing humidity.

-

Vibration Resistance:

- Designed to meet the typical industrial vibration resistance standards (e.g., IEC 60068-2-6).

-

Shock Resistance:

- IEC 60068-2-27 compliant for shock resistance.

-

Protection:

- The module generally has an IP20 rating, meaning it’s protected against solid objects larger than 12 mm, but not against water ingress.

Communication and Control:

-

RS-232/RS-485:

- Supports RS-232 for serial communication with external equipment or controllers.

- RS-485 allows for multi-drop communication with external devices, ideal for long-distance communication in industrial setups.

-

Ethernet/IP:

- Integrated Ethernet communication port for network communication, typically used for Modbus TCP or Ethernet/IP.

-

Modbus RTU/TCP:

- Supports Modbus communication protocol for integration with Modbus-compatible devices, facilitating data exchange with sensors, actuators, and controllers.

-

OPC Compatibility:

- Allows for OPC-based communication to interact with SCADA systems or other higher-level automation systems, providing data transparency and control.

Diagnostics and Configuration:

-

Software Configuration:

- Configuration is usually done via ZYGO’s proprietary software or compatible third-party PLC programming tools.

- Supports PC-based programming interfaces to configure I/O settings, communication parameters, and process control logic.

-

Diagnostic LEDs:

- Equipped with LED indicators for monitoring power, communication, and I/O status.

-

Self-Diagnostics:

- The module may include self-diagnostics for fault detection, ensuring that errors can be detected and corrected with minimal downtime.

-

Error Codes & Logs:

- Detailed error codes and log files help operators troubleshoot system issues more efficiently.

Applications:

-

Precision Optical Metrology:

- Ideal for integration into optical metrology systems used in industries like semiconductor manufacturing, aerospace, optics, and photonics.

-

Automation in High-Precision Industries:

- Perfect for automation tasks where precision and accuracy are crucial, such as in laser calibration, surface profiling, and alignment tasks.

-

Manufacturing Systems:

- Used in automated manufacturing systems to control processes requiring high-accuracy measurements and fine control, especially in industries like electronics and pharmaceuticals.

Key Features:

- Precision Control: Suitable for high-accuracy measurement and control processes.

- Flexible Communication: Supports Ethernet/IP, Modbus, and RS-485 for integration with existing systems.

- Multiple I/O Types: Includes a range of digital and analog inputs/outputs for versatile control options.

- Compact Design: Typically designed for DIN rail mounting, ideal for industrial control panels.

- Robust Diagnostics: Equipped with self-diagnostic tools and LED indicators for easy troubleshooting.

Let me know if you’d like more information about specific use cases or additional details!

3HAC046664-001 PLC

6GK1105-2AA10 PLC

9907-018 PLC

8520-MOP7 PLC

0200-10377 I/O

1FK7060-5AF71-1TH0 PLC

PCF2536-2500A PLC

JPAC-C343 PLC

TC-4000-P-PB-ES PLC

MC07B0220-503-4-00

MC07B0022-5A3-4-00 PLC

3500/25 149369-01 PLC

PR6423/003-030+CON021 PLC

AIO288 PLC

MPC240 PLC

ER20.X0A.M00

PP846

1797-IBN16

DKC11.1-040-7-FW

0-60063-1 PLC

PR4000B-F2V2

469-P1-HI-A20-E PLC

6AV6647-0AE11-3AX0

1747-ACNR15 PLC

6AV2124-1GC01-0AX0 PLC

1FT6086-1AF71-1EH1

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922