الوصف

Product Name:

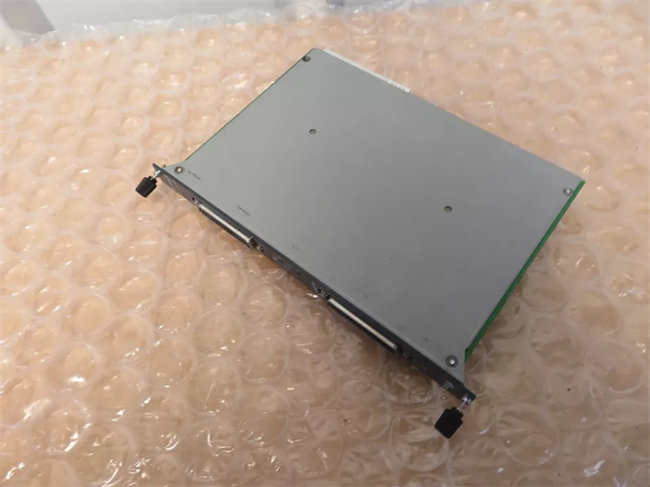

Ready Robotics Forge Controller Block 3 REV C & KEBA Pendant DCS PLC Module

Product Description:

The Ready Robotics Forge Controller Block 3 REV C paired with the KEBA Pendant DCS PLC Module represents a powerful automation solution designed for seamless control and operation of robotic and industrial automation systems.

The Forge Controller Block 3 is a cutting-edge controller designed specifically for industrial robotic applications. It offers a high level of flexibility, integration, and scalability, making it ideal for factory automation, robotics, and machine control. The KEBA Pendant DCS PLC Module, on the other hand, provides advanced control capabilities with real-time data communication, diagnostics, and remote control features, making it an essential part of industrial automation systems requiring complex, precise control.

Both components work together to offer a robust solution that simplifies the automation process, providing real-time performance feedback and detailed control features, while also ensuring ease of use and flexible system integration.

This combination of Forge Controller Block 3 REV C and KEBA Pendant DCS PLC Module is in great condition, ensuring top-tier performance and reliability for industries such as robotics, manufacturing automation, and machine control.

Product Parameters:

-

Model Number:

- Forge Controller Block 3 REV C

- KEBA Pendant DCS PLC Module

-

Manufacturer:

- Ready Robotics (Forge Controller)

- KEBA (Pendant DCS PLC Module)

-

Control System Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC)

-

Processor Type:

- High-performance processor for fast real-time control and decision-making

-

Communication Protocols Supported:

- Ethernet/IP, Modbus TCP, PROFIBUS, CANopen, and Serial Communication (RS232/RS485)

-

I/O Options:

- Digital and analog inputs/outputs

- Expandable I/O options

-

Mounting:

- DIN Rail (for KEBA Pendant DCS PLC Module)

- Rack-mounted/Compact (for Ready Robotics Forge Controller)

-

Temperature Range:

- Operating Temperature: 0°C to 60°C

- Storage Temperature: -20°C to 85°C

-

Power Supply:

- 24V DC (common power supply for industrial control systems)

-

Certifications:

- CE, UL, and other region-specific certifications

-

Status Indicators:

- LEDs for system status, communication, and diagnostics

Product Specifications:

Ready Robotics Forge Controller Block 3 REV C:

-

Processor and Performance:

- High-performance processor for handling complex robotic and automation tasks in real-time.

- Multi-tasking capability for simultaneous robotic and machine control.

-

Communication Interfaces:

- Ethernet/IP, Modbus TCP for industrial communication.

- PROFIBUS and CANopen for flexible integration with industrial devices.

- Multiple serial communication ports (RS232/RS485) for legacy equipment integration.

-

I/O Configuration:

- Digital I/O channels for basic on/off control.

- Analog I/O channels for precise control of continuous variables (e.g., temperature, pressure).

- Expandable I/O modules available for future system scaling.

-

Software Support:

- Ready Robotics Software for seamless programming and configuration of robots.

- Support for industry-standard programming languages and automation protocols.

- Compatible with 3rd-party software tools for advanced system programming and diagnostics.

-

Real-Time Control:

- Fast real-time control for robotic arm movements, assembly line processes, and machine control.

- Integrated real-time diagnostics for system health and performance feedback.

-

Safety and Error Detection:

- Watchdog timer for automatic system reset in case of failure.

- Built-in error detection and diagnostics for easy troubleshooting.

- Support for safe operation modes and failsafe logic.

-

Environmental Compatibility:

- Built to withstand industrial environments with protection against dust, moisture, and extreme temperatures.

- EMC-compliant design ensures minimal interference from other equipment.

KEBA Pendant DCS PLC Module:

-

Processor and Performance:

- High-performance processor for continuous data processing and real-time automation control.

- Multi-core processors for handling multiple tasks at once.

-

Communication Interfaces:

- Ethernet/IP, Modbus TCP, and PROFIBUS for seamless integration into industrial networks.

- Serial ports for communication with legacy devices.

- CANopen support for versatile communication with various industrial devices.

-

Input/Output Capability:

- Digital I/O: Multiple channels for basic signal control (e.g., relays, sensors).

- Analog I/O: Precision control for continuous signals like temperature and pressure readings.

- Expandable I/O modules to add additional inputs or outputs as required.

-

Mounting and Integration:

- DIN Rail mountable for easy installation into control cabinets.

- Compact form factor for easy integration in tight spaces.

-

Real-Time Diagnostics and Monitoring:

- Real-time status and diagnostics available via onboard display and LED indicators.

- Full system health monitoring with alerts for operational failures or faults.

-

Safety Features:

- Built-in safety protocols for safe data transmission and control operations.

- Error recovery mechanisms including system resets and watchdog timers.

-

Software and Programming:

- Compatible with KEBA software suite for system configuration, programming, and maintenance.

- Supports IEC 61131-3 compliant programming languages (Ladder Logic, Function Block Diagram, Structured Text, etc.).

-

Environmental Durability:

- Designed to operate within an industrial environment, with wide temperature tolerance and resistance to EMI (Electromagnetic Interference).

- IP20/67 rated for dust and moisture protection in varying environmental conditions.

Key Features:

-

High Flexibility: The integration of both the Forge Controller Block 3 and KEBA Pendant DCS PLC Module ensures that the system can handle complex robotic tasks and control multiple devices at once.

-

Multi-Protocol Communication: Supports Ethernet/IP, PROFIBUS, Modbus TCP, and CANopen, making it highly compatible with a variety of industrial devices.

-

Real-Time Performance: Both the Forge Controller and KEBA DCS PLC Module offer real-time feedback and control, ensuring that tasks are executed efficiently with minimal latency.

-

Expandable I/O Options: Both units provide flexible I/O options for expansion as per application requirements, allowing the system to scale with future needs.

-

Diagnostic Capabilities: Built-in diagnostic functions for error detection, troubleshooting, and system health monitoring, ensuring reliable and continuous operations.

-

Industrial Compatibility: Designed for harsh industrial environments, with EMC compliance, IP-rated protection, and wide temperature tolerances.

-

Safety Features: Advanced safety mechanisms such as watchdog timers, error detection, and automatic recovery for safe system operation.

-

Compact and Easy Integration: Both components are compact and offer easy integration with existing industrial systems, making them suitable for a variety of applications.

Applications:

-

Robotics and Automation: Ideal for controlling industrial robots, including robotic arms, assembly lines, and automated manufacturing processes.

-

Manufacturing Automation: Used in smart factories for controlling and automating production lines, testing stations, and machinery.

-

Machine Control: Suitable for controlling CNC machines, packaging machines, and material handling systems.

-

Process Control: Utilized in industries like chemical manufacturing, food and beverage, and pharmaceuticals for controlling variables such as temperature, pressure, and flow.

-

Energy Systems: Can be used in energy management, including solar panel control, HVAC systems, and lighting automation.

Conclusion:

The Ready Robotics Forge Controller Block 3 REV C and KEBA Pendant DCS PLC Module provide a comprehensive and robust solution for industrial automation. Together, they offer real-time control, diagnostics, flexible I/O capabilities, and scalable system integration. With built-in safety features and broad compatibility with industrial communication protocols, this combination is perfect for robotic applications, manufacturing automation, and machine control across industries.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922