الوصف

The Kollmorgen S22460-SRS is a module from Kollmorgen’s DCS (Distributed Control System) and PLC (Programmable Logic Controller) series, typically used for process control and automation applications. Below is a detailed overview of the product, including its name, description, parameters, and specifications.

Product Name:

- Kollmorgen S22460-SRS – DCS PLC Module

Product Description:

The Kollmorgen S22460-SRS is an integral component of Kollmorgen’s motion control systems and automation platforms, providing control and monitoring functions within an industrial automation environment. This module is part of Kollmorgen’s comprehensive suite of industrial controllers, offering a robust and flexible solution for motion control, process automation, and system integration.

It is typically used in motion control systems, enabling precise control of motors, actuators, and sensors while ensuring real-time monitoring and feedback in process control systems. The S22460-SRS is designed for high reliability and performance in demanding applications such as robotics, packaging, assembly lines, and other complex automation processes that require precise control.

Product Parameters & Specifications:

General Information:

- Module Type: DCS PLC Motion Control Module.

- Application Area: Suitable for industrial automation, motion control, robotics, and process control in manufacturing, assembly, and packaging industries.

- Series: Kollmorgen S Series (part of Kollmorgen’s motion control system).

- Communication Type: Supports various communication protocols for integration with other systems and controllers.

Electrical Specifications:

- Input Voltage: Typically operates at 24V DC (for the module itself; however, motor and actuator voltage requirements will differ based on system design).

- Power Consumption: Power consumption varies depending on the configuration, load, and peripheral devices connected.

- Current Consumption: Specific current values will depend on the connected load and operational conditions, typically around 300mA to 1A under typical conditions.

- Output Power: Output power depends on the connected motion control devices and actuators.

I/O Capacity and Capability:

- Digital I/O: Features a high count of digital I/O points for on/off control of connected equipment and devices.

- Analog I/O: Supports analog inputs and outputs (e.g., 4-20mA or 0-10V) for precise control of sensors, actuators, and other devices.

- Motion Control: Interfaces with servo motors, stepper motors, and other motion control devices, offering real-time control and feedback.

Communication Protocols:

- Ethernet/IP: Provides high-speed communication over Ethernet networks for integration with enterprise-level systems and devices.

- Modbus RTU/TCP: A widely used industrial protocol for communication with PLCs and other control systems.

- CANopen: A popular protocol for industrial automation that enables easy integration of motion control and sensor devices.

- Profinet/PROFIBUS: For connecting to field devices, sensors, and drives in industrial environments.

- Serial Communication (RS232/RS485): Provides flexibility for legacy and non-networked devices.

Performance and Real-Time Control:

- Real-Time Control: Enables precise, low-latency motion and process control in industrial applications.

- Motion Control Accuracy: Supports high-resolution feedback systems (e.g., encoders, resolvers) to ensure accurate positioning and speed control.

- High-Speed Processing: Capable of fast, real-time processing of data, particularly important for systems requiring quick response times like robotics or automated production lines.

Environmental Specifications:

- Operating Temperature Range: Typically 0°C to 55°C (32°F to 131°F), depending on the application.

- Storage Temperature Range: Typically -20°C to 70°C (-4°F to 158°F).

- Humidity: Designed to operate in environments with 5% to 95% non-condensing humidity.

- Vibration Resistance: Built to endure industrial vibrations as per standard IEC specifications.

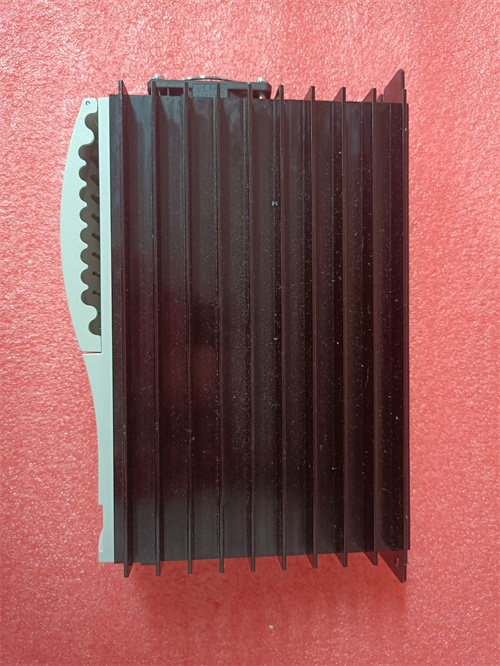

Physical Specifications:

- Dimensions: The specific physical dimensions depend on the model and configuration, but typical dimensions may range between 150mm x 120mm x 50mm (W x H x D).

- Weight: Depending on configuration, the weight of the module typically ranges between 1-2 kg (2.2 – 4.4 lbs).

- Enclosure Type: Industrial-grade housing, designed to be mounted on control panels or integrated into larger automation systems.

Software and Programming:

- Programming Environment: Kollmorgen’s proprietary software and programming tools for motion and process control, such as Kollmorgen Automation Suite (KAS), which provides a rich set of tools for configuration, monitoring, and programming.

- PLC Programming: Supports standard programming languages such as IEC 61131-3 (Ladder Logic, Structured Text, Function Block Diagram, etc.), commonly used for automation programming.

- Motion Programming: Includes motion-specific functions such as positioning, speed control, and torque control for integration with Kollmorgen servo drives and motors.

Reliability & Redundancy:

- Redundancy Features: Some configurations offer optional redundancy features for critical control functions, ensuring system uptime in mission-critical applications.

- Built-In Diagnostics: Advanced diagnostic and monitoring capabilities to detect faults in connected devices or control processes.

Key Features & Benefits:

- High-Performance Motion Control: Designed for real-time motion control applications, offering precise control of servo motors and actuators.

- Scalability and Flexibility: The system can be expanded and customized for a wide range of industrial applications, from robotics to automated assembly lines.

- Multiple Communication Protocols: Supports various industrial communication standards such as Ethernet/IP, Modbus, Profinet, and CANopen, ensuring seamless integration with other control systems and devices.

- Real-Time Feedback: High-speed control and feedback loops for motion control ensure maximum precision and accuracy in dynamic applications.

- Ease of Integration: Easy to integrate with Kollmorgen’s other motion control components, such as servo drives, actuators, and motors.

Applications:

- Motion Control Systems: Ideal for applications in robotics, assembly lines, packaging, material handling, and automated manufacturing.

- Process Control: Used in industries such as automotive, food & beverage, pharmaceutical, and electronics manufacturing, where precision and efficiency are essential.

- Machine Automation: Helps automate complex machines and systems in industries requiring high accuracy and reliable control, such as CNC machinery and test equipment.

Conclusion:

The Kollmorgen S22460-SRS module is a high-performance, flexible solution for motion control and process automation in industrial environments. With its wide range of I/O capabilities, real-time control, and multiple communication protocols, it’s an ideal choice for applications requiring precise motion control, high-speed data processing, and integration with other industrial automation systems. This module contributes to optimizing production processes, improving efficiency, and ensuring reliability across various industries.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922