الوصف

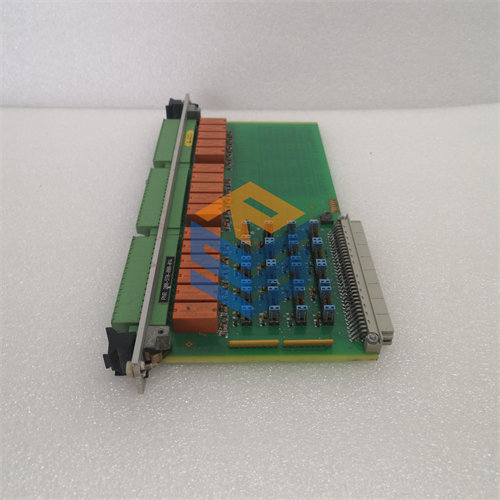

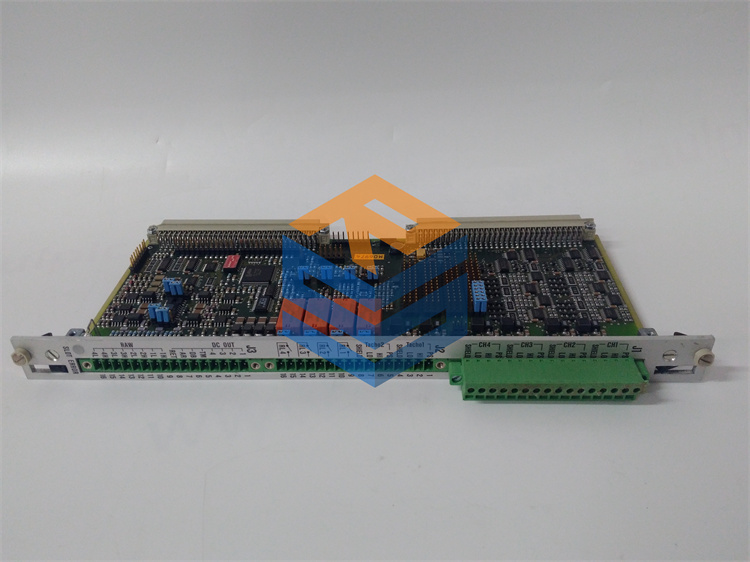

The VIBRO-METER VM600 IOC4T (Input/Output Card 4-channel Tachometer) is an essential signal interface module within the VM600 series machinery protection and condition monitoring system. It primarily acts as the physical connection point for sensors and provides the necessary I/O for its companion processing module, the MPC4 (Machinery Protection Card 4-channel).

SEO Optimized Headings:

- VIBRO-METER VM600 IOC4T: 4-Channel Input/Output Card for Machinery Protection.

- VM600 IOC4T (200-560-000-018 & 200-560-101-015): Sensor Interface for MPC4 Protection Systems.

- VIBRO-METER VM600 Series: Reliable I/O for Critical Machine Monitoring.

- IOC4T Module: Essential for MPC4 Card Pairs in Industrial Safety Systems.

- Machinery Protection I/O Card: Enabling Real-time Sensor Data for Alarms and Shutdowns.

Product Overview:

The VIBRO-METER VM600 IOC4T is a crucial interface card for the VM600 rack-based machinery protection system. It is specifically designed to work in a card pair configuration with the VM600 MPC4 (Machinery Protection Card 4-channel). The IOC4T is responsible for:

- Providing the physical connection points for 4 dynamic signal inputs (e.g., vibration, displacement) and 2 tachometer (speed/phase reference) inputs.

- Supplying power to connected sensors.

- Offering built-in relays for alarming.

- Providing buffered “raw” sensor signals for external analysis.

- Converting processed signals from the MPC4 into analog (DC) outputs (voltage or current).

- Protecting all inputs and outputs against electromagnetic interference (EMI) and signal surges.

Regarding the specific part numbers (200-560-000-018 and 200-560-101-015):

These different part numbers typically denote minor hardware revisions, firmware versions, or specific factory configurations. While detailed public datasheets explicitly outlining the differences between these exact sub-variants are not common, such numerical variations usually reflect:

- Minor component updates for obsolescence management or improved manufacturing.

- Updates to embedded firmware that might enhance performance or address specific issues.

- Specific internal feature sets or enabled capabilities that are not universally present across all IOC4T variants (e.g., slight differences in relay configurations or output options).

Both part numbers belong to the VM600 IOC4T family and share the core functionalities of a 4-channel I/O card for machinery protection. For precise details on differences, it is best to consult the manufacturer (Parker Meggitt) or their authorized distributors with the full part numbers.

Product Details:

The VIBRO-METER VM600 IOC4T (200-560-000-018 / 200-560-101-015) is a robust input/output card that forms the critical link between machinery sensors and the protection and monitoring capabilities of the VM600 system. Its primary role is to ensure reliable and safe operation of rotating machinery by providing accurate sensor data to the MPC4 processing card.

Consider a critical pump in an oil refinery. This pump is equipped with proximity probes to measure shaft vibration and axial position, and a speed sensor for RPM monitoring. The wiring from these sensors would be terminated directly onto the screw terminals on the front panel of the IOC4T (which is located at the rear of the VM600 rack). The IOC4T not only passes these raw signals to the associated MPC4 card for processing and protection, but also provides vital features like sensor power, EMI protection, and local alarm relays. If a vibration level exceeds a programmed danger limit, the MPC4 can trigger a relay on the IOC4T, which in turn can initiate a machine shutdown to prevent catastrophic failure. The IOC4T also provides buffered raw signals, allowing technicians to connect portable diagnostic equipment without interrupting the protection system.

Here’s a breakdown of its key functionalities and attributes:

1. Sensor Interface and Signal Conditioning:

- 4 Dynamic Inputs: Provides robust connections for four dynamic measurement channels. These are typically used for vibration (absolute or relative) or displacement measurements from sensors like accelerometers or proximity probes.

- 2 Tachometer Inputs: Includes two dedicated channels for speed and phase reference signals from tachometer probes or magnetic pick-ups, essential for order-based analysis and speed-dependent alarming.

- Transducer Power: Supplies power to various types of connected sensors, including proximity systems and IEPE/ICP® accelerometers, simplifying field wiring.

- Signal Integrity: Protects all inputs and outputs against electromagnetic interference (EMI) and transient voltage surges, ensuring clean and reliable signal transmission in harsh industrial environments.

2. Integration with MPC4 (Card Pair):

- Slave Operation: The IOC4T operates in slave mode to its associated MPC4 machinery protection card. Each IOC4T is mounted in the rear card cage of a VM600 ABE04x or ABE056 rack, directly behind its corresponding MPC4 module which resides in the front card cage.

- Dedicated Communication: It communicates with the MPC4 via a dedicated internal interface (often an Industry Pack (IP) interface), passing raw sensor signals to the MPC4 for processing.

- Processed Signal Return: Once the MPC4 processes the dynamic and tachometer signals (e.g., filtering, peak detection, DC gap), it sends the processed information back to the IOC4T.

3. Outputs and Alarming:

- Analog DC Outputs: Provides four analog DC outputs (one per dynamic channel). These outputs are configurable as either 0 to 10 VDC voltage outputs or 4 to 20 mA current outputs (selectable via jumpers on the card). These are typically used to send processed vibration or displacement values to external systems like DCS (Distributed Control Systems) or PLCs (Programmable Logic Controllers).

- Local Relays: Contains four local relays (RL1 to RL4) that can be configured under software control to respond to specific alarm signals generated by the MPC4 (e.g., Alert, Danger, Sensor OK status). These can be configured as Normally Energized (NE) or Normally De-Energized (NDE) contacts.

- Buffered “Raw” Outputs: Features BNC connectors on the front panel (rear of the VM600 rack) that provide direct, buffered access to the raw, unprocessed dynamic sensor signals. This is invaluable for connecting portable diagnostic equipment (e.g., oscilloscopes, data collectors) without affecting the primary monitoring system.

- Programmable Open-Collector Outputs: Can provide 32 fully-programmable open-collector outputs (jumper selectable) for interfacing with other relay cards like the IRC4 or RLC16.

- Control Inputs: Includes control inputs like Alarm Reset (AR), Danger Bypass (DB), and Trip Multiplier (TM), allowing external control over certain protection functions.

Technical Specifications (Typical for VM600 IOC4T):

The following specifications are generally applicable to the IOC4T family. Specific values might vary slightly between particular part numbers and generations. The provided part numbers (200-560-000-018 and 200-560-101-015) represent specific configurations within this range.

Applications and Industries:

The VIBRO-METER VM600 IOC4T is indispensable in applications requiring reliable machinery protection and basic condition monitoring for critical rotating machinery. Its role is to accurately interface with sensors and provide the necessary I/O for the MPC4 card to perform its protective functions.

Consider a large centrifugal compressor in a natural gas processing plant. The safety and continuous operation of this asset are paramount. Proximity probes and accelerometers installed on the compressor would connect directly to the IOC4T modules in the VM600 rack. The IOC4T ensures these signals are reliably transmitted to the MPC4 cards, which continuously monitor critical parameters like overall vibration levels, shaft position, and speed. If any parameter exceeds a pre-set alarm or danger limit, the MPC4, through the IOC4T’s integrated relays, can initiate an alarm, a warning, or even a critical machine shutdown to prevent costly damage or safety incidents. The IOC4T’s buffered outputs also allow maintenance engineers to easily connect diagnostic tools for troubleshooting without interfering with the live protection system.

Key applications and industries that extensively utilize the IOC4T include:

- Power Generation:

- Turbines (Gas, Steam, Hydro), Generators: For machinery protection and basic condition monitoring of vibration, bearing wear, and shaft position to prevent catastrophic failures.

- Auxiliary Equipment: Monitoring critical pumps, fans, and motors.

- Oil & Gas:

- Refineries, Pipelines, Offshore Platforms, LNG Plants: Essential for protection of turbomachinery (compressors, pumps, gas turbines) where safety and uptime are critical, often conforming to API 670 standards.

- Chemical and Petrochemical Industries:

- Monitoring vital rotating equipment in hazardous environments to ensure safe operation and prevent unplanned shutdowns.

- Heavy Manufacturing (e.g., Steel, Cement, Pulp & Paper):

- Protecting large motors, gearboxes, and production machinery where a single failure can lead to significant production losses.

- Marine Applications:

- Ensuring the reliability and safety of propulsion systems, auxiliary engines, and other critical machinery on large vessels.

In essence, the VM600 IOC4T is fundamental to robust machinery protection systems, providing the reliable I/O necessary to safeguard high-value assets and ensure operational continuity.

Related Products:

The VIBRO-METER VM600 IOC4T modules (including 200-560-000-018 and 200-560-101-015) are integral parts of a complete VM600 system and require several other components to function as a full machinery protection and monitoring solution.

- Companion Processing Module (Card Pair):

- VM600 MPC4 (Machinery Protection Card 4-channel): The IOC4T always pairs with an MPC4 card. The MPC4 performs the actual signal processing, monitoring, and alarm generation for machinery protection. The IOC4T provides the physical I/O interface for the MPC4.

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U (or 1U for ABE056) rack housings where the IOC4T is physically installed (in the rear card cage), directly behind its companion MPC4.

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power (+5 VDC, ±12 VDC) to the VM600 rack’s backplane and all installed modules, including the IOC4T. Redundant RPS6U units are highly recommended for critical protection systems.

- Rack Controller and Communication Modules (Optional but Common):

- VM600 CPUM / CPUR2 / CPUMMk2: While the MPC4/IOC4T pair can operate independently for protection, a CPUM module is often included in the rack to manage system configuration, provide higher-level communication interfaces (e.g., Ethernet), and allow integration with supervisory systems.

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller, providing additional communication ports.

- Relay Output Expansion Cards (Optional):

- VM600 IRC4 (Intelligent Relay Card): Provides additional programmable relay outputs if the 4 relays on the IOC4T are insufficient.

- VM600 RLC16 (Relay Card 16): Offers 16 additional relays, often driven by the IOC4T’s open-collector outputs.

- Sensors:

- Various types of industrial sensors connect to the IOC4T, including proximity probes, accelerometers, and magnetic pick-ups/tachometer sensors.

- Configuration Software:

- VM600 MPSx Software: Used for configuring the MPC4/IOC4T card pair, defining alarm limits, and setting up relay logic.

- VibroSight®: While primarily for condition monitoring, VibroSight can also connect to VM600 racks via the CPUM to view protection system status and historical data.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922