الوصف

I see you’re asking about two specific part numbers related to the Vibro-Meter VM600 XIO16T module. To provide you with the most accurate and current information, I need to look up details for both of these.

What are the specific differences in features or compatibility between the Vibro-meter 620-002-000-113 and the 620-003-111-112 versions of the VM600 XIO16T? How does the VM600 XIO16T module integrate with other VM600 components, such as the CMC16 or XMV16 cards, to form a complete monitoring system? What are the detailed technical specifications, including input types, voltage ranges, and output capabilities, for the Vibro-meter 620-002-000-113 VM600 XIO16T? What are the detailed technical specifications, including input types, voltage ranges, and output capabilities, for the Vibro-meter 620-003-111-112 VM600 XIO16T? Vibro-meter 620-002-000-113 VM600 XIO16T datasheet Vibro-meter 620-003-111-112 VM600 XIO16T specifications VM600 XIO16T module functions VM600 XIO16T applications Vibro-meter XIO16T compatibility XIO16T current status (active/obsolete) How to configure Vibro-meter XIO16T You’re asking about two specific part numbers for the Vibro-Meter VM600 XIO16T module: 620-002-000-113 and 620-003-111-112.

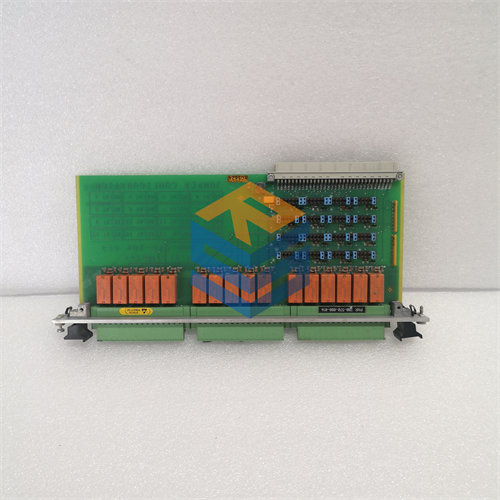

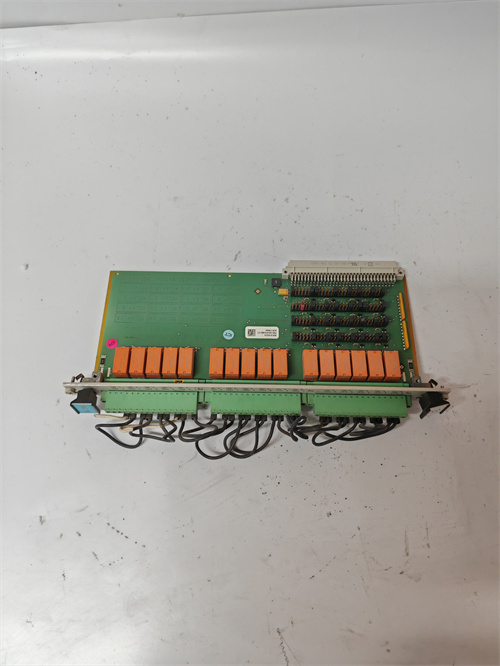

The VM600 XIO16T is an Extended Input/Output (I/O) module that always functions as a “card pair” with an XMx16 processing module (either an XMV16 for vibration monitoring or an XMC16 for combustion monitoring). It provides the physical interface for sensors and external communications, acting as the bridge between the machine’s transducers and the sophisticated processing capabilities of the companion XMx16 card.

While comprehensive public datasheets detailing the precise differences between 620-002-000-113 and 620-003-111-112 are not readily available, it’s common for these variations in part numbers to indicate:

- Minor Hardware Revisions: Small changes to components or board layout.

- Firmware Versions: Different pre-installed firmware versions that might optimize performance or add minor features.

- Specific Certifications: Tailored for particular industry standards or regional requirements.

- Input/Output Configuration: Subtle differences in default input ranges, filtering, or specific output capabilities, though the core functionality of 16 dynamic and 4 tachometer channels remains consistent across the XIO16T family.

Essentially, both part numbers refer to the XIO16T, which is the crucial I/O front-end for the advanced condition monitoring capabilities of the VM600 system.

SEO Optimized Headings:

- VIBRO-METER VM600 XIO16T (620-002-000-113 & 620-003-111-112): Extended Input/Output Module.

- VM600 XIO16T: The Sensor Interface for Advanced Condition Monitoring.

- VIBRO-METER 620-002-000-113 & 620-003-111-112: Enabling High-Channel Data Acquisition.

- VM600 Input/Output Module: Connecting Transducers to Condition Monitoring Systems.

- XIO16T Card Pair: Supporting XMV16 and XMC16 for Machinery Diagnostics.

- VIBRO-METER VM600 Series: Robust I/O for Critical Asset Monitoring.

Product Overview:

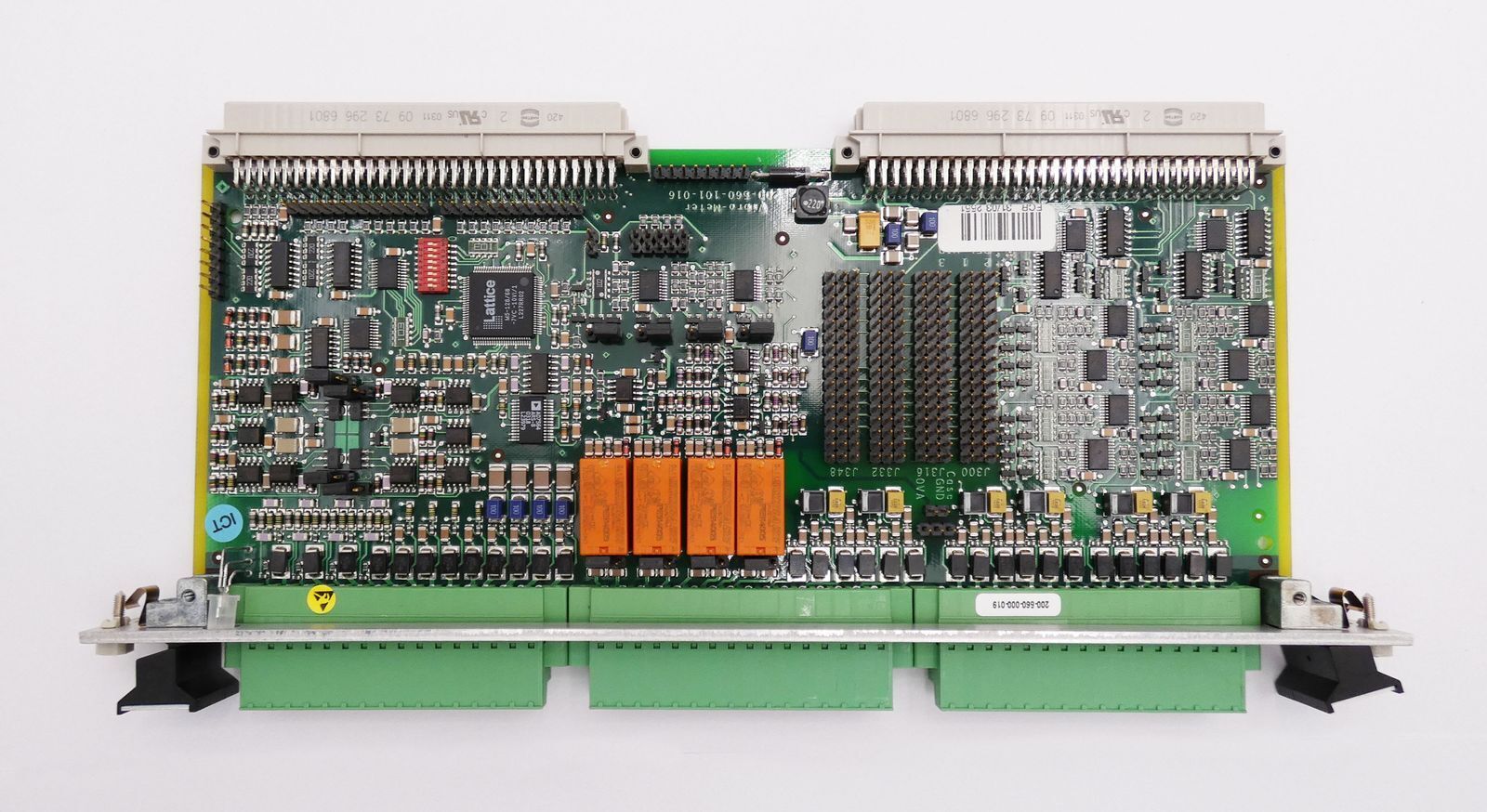

The VIBRO-METER VM600 XIO16T (represented by part numbers such as 620-002-000-113 and 620-003-111-112) is a critical Input/Output (I/O) module within the VM600 rack-based machinery monitoring system. It serves as the bridge between various industrial sensors and the advanced processing capabilities of its companion module, either the XMV16 (Extended Vibration Monitoring) or XMC16 (Extended Combustion Monitoring) card.

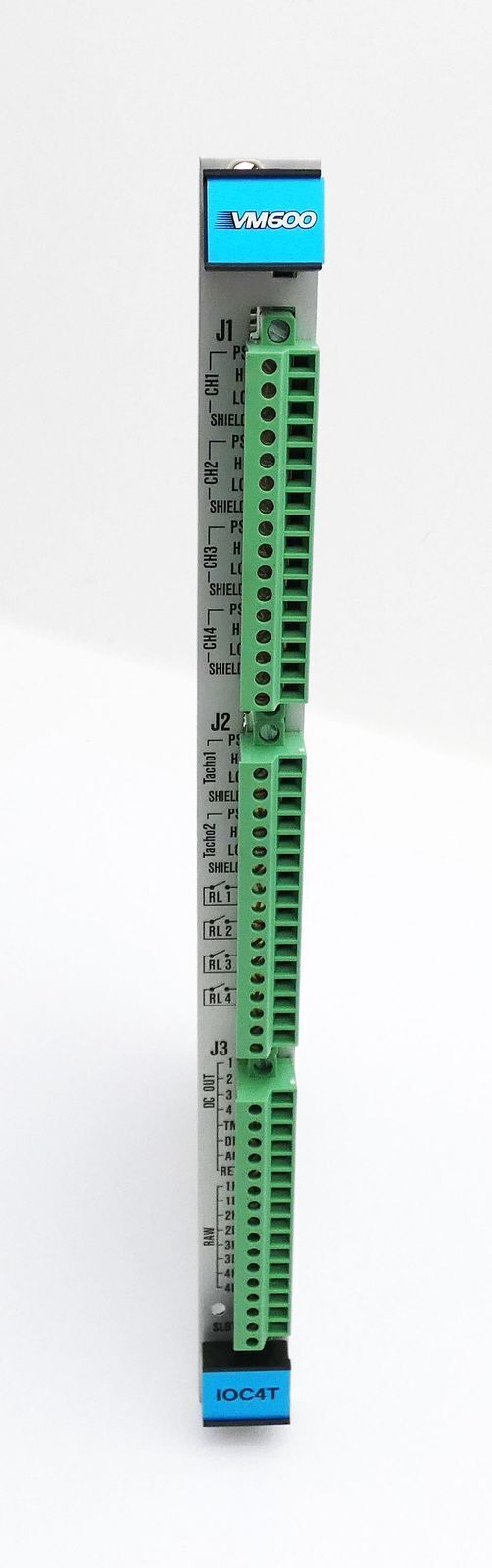

The XIO16T handles the physical connections for 16 dynamic channels (for vibration, pressure, etc.) and 4 tachometer (speed/phase reference) channels. Its key functions include:

- Signal Conditioning: Performing initial analog signal conditioning to ensure clean and accurate data.

- Sensor Power Supply: Providing power to connected transducers.

- Input Protection: Protecting the system from surges and electromagnetic interference (EMI).

- Physical Connectivity: Offering robust screw terminal connectors for field wiring.

- Buffered Outputs: Providing raw, buffered sensor signals via BNC connectors for external diagnostic tools.

It is fully software configurable via the VM600’s Central Processing Unit Module (CPUM or CPUR) and the VibroSight® software.

Product Details:

The VIBRO-METER VM600 XIO16T (620-002-000-113 / 620-003-111-112) plays an indispensable role in detailed machinery diagnostics and predictive maintenance. While the companion XMV16 or XMC16 module performs the complex digital signal processing (DSP) like FFTs, the XIO16T is responsible for reliably bringing the raw data from the machinery into the system.

Consider a large gas turbine where multiple points of vibration, shaft position, and combustion dynamics need to be precisely monitored. Proximity probes, accelerometers, and pressure sensors are installed on the turbine. These sensors are then wired directly to the physical terminals on the XIO16T module, located at the rear of the VM600 rack. The XIO16T conditions these analog signals, applies necessary filtering, and then passes them on to the XMV16 or XMC16 card for high-resolution analog-to-digital conversion and advanced analysis. This modular approach ensures signal integrity and allows for flexibility in system configuration.

Here’s a breakdown of its key functionalities and attributes:

1. Sensor Interface and Signal Conditioning:

- 16 Dynamic Inputs: Accepts signals from various dynamic transducers such as proximity probes (for displacement, relative vibration, axial position), accelerometers (for absolute vibration), velocity transducers, and dynamic pressure sensors.

- 4 Tachometer Inputs: Handles signals from speed and phase reference sensors (e.g., proximity probes, magnetic pick-ups, TTL sensors) for rotational speed and phase information. Tachometer channels 1 & 2 often support voltage and current inputs, while 3 & 4 might be voltage-only.

- Analog Signal Conditioning: Performs crucial initial conditioning of the analog signals (e.g., filtering, amplification) before they are passed to the processing module.

- Transducer Power: Provides excitation power for various types of sensors directly from the module, simplifying wiring and reducing external power supply needs.

2. Physical Connectivity and Robustness:

- Rear-Mounted I/O: The XIO16T is mounted at the rear of the VM600 rack, directly behind its companion XMV16 or XMC16 processing module, forming a robust “card pair.” This design minimizes cable lengths and reduces potential for noise.

- Screw Terminal Connectors: Features secure screw terminal connectors for reliable field wiring of sensors and outputs.

- Input Protection: Designed with robust protection against signal surges, over-voltage, and electromagnetic interference (EMI), ensuring data integrity and system reliability in harsh industrial environments. Meets relevant EMC standards.

3. Outputs and System Integration:

- Buffered Raw Outputs: A key feature for advanced diagnostics. BNC connectors on the front of the XIO16T (or sometimes its companion XMV16/XMC16) provide direct, buffered access to the raw, unprocessed sensor signals. This allows maintenance engineers to connect portable diagnostic equipment (e.g., data collectors, oscilloscopes) without disturbing the active monitoring system.

- Internal Bus Sharing: Input signals can be shared internally within the VM600 rack via the “Raw Bus” and “Tacho Bus,” allowing other cards (e.g., MPC4 protection cards) to access the same sensor data without additional external wiring.

- Communication Pathway: While the XIO16T primarily handles physical I/O, it facilitates the communication pathway for the XMx16 processing module to send processed data (e.g., FFTs, trends, alarms) to the rack’s CPUM (Central Processing Unit Module) and then to the VibroSight® software on a host computer via Ethernet.

Differences between 620-002-000-113 and 620-003-111-112: As noted, precise differences are often not publicly detailed. However, the varying last digits (-113 vs. -112) usually denote incremental revisions. These could be:

- Minor component changes for obsolescence management or improved performance.

- Firmware updates that might slightly alter input handling or diagnostic features.

- Manufacturing batch differences or specific internal options. Functionally, for typical applications, both parts will serve the same core purpose as the I/O interface for an XMV16 or XMC16. It’s best to consult official documentation or a Meggitt/Parker representative for exact distinctions if highly specific compatibility or feature requirements exist.

Technical Specifications (Typical for VM600 XIO16T, including 620-002-000-113 & 620-003-111-112 variants):

The specifications are generally consistent across the XIO16T family, as they serve the same core interfacing function for the XMx16 processing cards.

A VIBRO-METER VM600 XIO16T is an Input/Output (I/O) module within the VM600 series of machinery monitoring systems. It acts as the physical interface between the sensors on a machine and the sophisticated processing cards (like the XMV16 or XMC16) in the VM600 rack.

You’ve provided two specific part numbers: 620-002-000-113 and 620-003-111-112. Both refer to variants of the XIO16T.

SEO Optimized Headings:

- VIBRO-METER VM600 XIO16T: Extended Input/Output Module for Condition Monitoring.

- VM600 XIO16T (620-002-000-113 & 620-003-111-112): Sensor Interface for Advanced Diagnostics.

- VIBRO-METER VM600 Series: Robust I/O for High-Channel Machinery Monitoring.

- XIO16T Module: Essential for XMV16/XMC16 Card Pairs in Industrial Systems.

- Condition Monitoring I/O Card: Precision Data Acquisition for Predictive Maintenance.

Product Overview:

The VIBRO-METER VM600 XIO16T is a critical component of the VM600 rack-based machinery protection and condition monitoring system. It is specifically designed to work as a card pair with an XMx16 processing module (either an XMV16 for vibration monitoring or an XMC16 for combustion monitoring). The XIO16T handles all the physical aspects of connecting to industrial sensors and provides the initial signal conditioning.

Key functions of the XIO16T include:

- Providing 16 dynamic input channels for various transducers (e.g., accelerometers, proximity probes).

- Offering 4 tachometer/speed channels for rotational speed and phase reference.

- Supplying transducer power to the connected sensors.

- Protecting inputs from surges and electromagnetic interference (EMI).

- Providing buffered raw outputs for connecting external diagnostic equipment.

The different part numbers you’ve listed (620-002-000-113 and 620-003-111-112) typically denote minor hardware revisions, firmware versions, or specific input/output configurations within the XIO16T product family. Functionally, they both serve as the robust I/O interface for the VM600’s advanced condition monitoring cards.

Product Details:

The VIBRO-METER VM600 XIO16T (620-002-000-113 / 620-003-111-112) is the essential front-end module for high-channel count condition monitoring applications within the VM600 system. It addresses the practical challenges of integrating numerous sensors from a machine into a sophisticated monitoring system.

Consider a large industrial compressor train that requires detailed vibration and performance monitoring. Numerous accelerometers, displacement probes, and speed sensors are mounted on the compressor, its gearbox, and motor. The wiring from these sensors terminates at the XIO16T modules, which are installed in the rear of the VM600 rack. The XIO16T ensures that the delicate sensor signals are properly conditioned, protected from electrical noise and surges, and then accurately passed to the companion XMV16 processing cards in the front of the rack. This seamless and reliable signal path is crucial for the XMV16 to perform its high-resolution data acquisition and analysis, enabling proactive maintenance decisions.

Here’s a breakdown of its key functions and attributes:

1. Sensor Interface and Signal Conditioning:

- High-Density Inputs: Provides physical connections for 16 dynamic measurement channels (e.g., for vibration, dynamic pressure) and 4 tachometer channels (for speed and phase reference).

- Universal Input Compatibility: The inputs are designed to accept signals from a wide range of industrial transducers, including:

- Dynamic: Accelerometers (IEPE/ICP® compatible), proximity probes (for relative vibration, displacement, axial position), velocity transducers, and dynamic pressure sensors.

- Tachometer: Proximity probes, magnetic pick-ups, and TTL signals. Some tachometer channels may support both voltage and current inputs.

- Analog Signal Conditioning: Performs critical initial analog signal conditioning, including filtering and amplification, to prepare the raw signals for accurate analog-to-digital conversion by the companion XMx16 module.

- Transducer Power Supplies: Built-in power supplies deliver excitation voltage to various sensor types, simplifying wiring and reducing the need for external power sources.

2. Robust Physical Design and Protection:

- Card Pair Functionality: The XIO16T always operates as a “card pair” with an XMV16 (for vibration) or XMC16 (for combustion) processing module. The XIO16T is mounted in the rear card cage of the VM600 rack, directly behind its corresponding XMx16 module which sits in the front card cage.

- Secure Connections: Utilizes robust screw terminal connectors for reliable and secure connection of field wiring from sensors.

- EMI and Surge Protection: Designed with robust protection features against electromagnetic interference (EMI) and transient voltage surges, ensuring signal integrity and system resilience in harsh industrial environments. This is crucial for meeting EMC standards.

3. Data Routing and System Integration:

- Buffered Raw Outputs: A key feature for advanced diagnostics is the provision of buffered raw sensor signals via BNC connectors. This allows maintenance personnel to connect portable data collectors or oscilloscopes directly to the live sensor signals without disrupting the operational monitoring system.

- Internal Bus Integration: The XIO16T enables internal signal sharing within the VM600 rack. Input signals can be routed via the VM600’s “Raw Bus” and “Tacho Bus” to other modules (e.g., MPC4 protection cards), reducing redundant external wiring.

- Data Pathway to Processing: While the XIO16T handles the physical I/O, it forms the critical link for raw data transfer to the associated XMV16/XMC16 processing module, which then performs sophisticated digital signal processing (DSP), FFT analysis, and sends processed data to the rack’s CPUM and ultimately to the VibroSight® software.

Differences between 620-002-000-113 and 620-003-111-112: Specific, publicly available documentation detailing the exact differences between these two part numbers is often limited. Typically, variations in the last digits of Vibro-Meter part numbers (like -113 vs. -112) signify:

- Minor internal hardware revisions (e.g., component changes for obsolescence management, board layout optimizations).

- Pre-installed firmware versions that might offer subtle performance enhancements or bug fixes.

- Specific internal options or factory configurations that are not outwardly visible but warrant a unique part number. For most common applications, both modules will perform the core function of an XIO16T, providing the necessary I/O for 16 dynamic and 4 tachometer channels. If precise compatibility or feature verification is required, consulting official Meggitt/Parker documentation or their technical support is recommended.

Technical Specifications (Typical for VM600 XIO16T, including 620-002-000-113 & 620-003-111-112 variants):

The specifications are generally consistent across the XIO16T family, serving as the standard interface for the XMx16 processing cards.

The VIBRO-METER VM600 XIO16T is a crucial component within the VM600 series of machinery monitoring systems. It acts as the Input/Output (I/O) module that physically connects to the sensors on a machine and communicates with the sophisticated processing cards within the VM600 rack.

You’ve provided two specific part numbers: 620-002-000-113 and 620-003-111-112. Both refer to variants of the XIO16T module.

SEO Optimized Headings:

- VIBRO-METER VM600 XIO16T: Extended Input/Output Module for Condition Monitoring.

- VM600 XIO16T (620-002-000-113 & 620-003-111-112): Sensor Interface for Advanced Diagnostics.

- VIBRO-METER VM600 Series: Robust I/O for High-Channel Machinery Monitoring.

- XIO16T Module: Essential for XMV16/XMC16 Card Pairs in Industrial Systems.

- Condition Monitoring I/O Card: Precision Data Acquisition for Predictive Maintenance.

Product Overview:

The VIBRO-METER VM600 XIO16T is an integral part of the VM600 rack-based machinery protection and condition monitoring system. It is specifically designed to function as a card pair with an XMx16 processing module (either an XMV16 for vibration monitoring or an XMC16 for combustion monitoring). The XIO16T’s primary role is to handle the physical interface with industrial sensors and perform initial signal conditioning.

Key functions of the XIO16T include:

- Providing 16 dynamic input channels for various transducers (e.g., accelerometers, proximity probes).

- Offering 4 tachometer/speed channels for rotational speed and phase reference.

- Supplying transducer power to the connected sensors.

- Protecting inputs from surges and electromagnetic interference (EMI).

- Providing buffered raw outputs for connecting external diagnostic equipment.

The different part numbers you’ve listed (620-002-000-113 and 620-003-111-112) typically denote minor hardware revisions, firmware versions, or specific input/output configurations within the XIO16T product family. Functionally, they both serve as the robust I/O interface for the VM600’s advanced condition monitoring cards.

Product Details:

The VIBRO-METER VM600 XIO16T (620-002-000-113 / 620-003-111-112) plays an indispensable role in detailed machinery diagnostics and predictive maintenance. While the companion XMV16 or XMC16 module performs the complex digital signal processing (DSP) like FFTs, the XIO16T is responsible for reliably bringing the raw data from the machinery into the system.

Consider a large industrial compressor train that requires detailed vibration and performance monitoring. Numerous accelerometers, displacement probes, and speed sensors are mounted on the compressor, its gearbox, and motor. The wiring from these sensors terminates at the XIO16T modules, which are installed in the rear of the VM600 rack. The XIO16T ensures that the delicate sensor signals are properly conditioned, protected from electrical noise and surges, and then accurately passed to the companion XMV16 processing cards in the front of the rack. This seamless and reliable signal path is crucial for the XMV16 to perform its high-resolution data acquisition and analysis, enabling proactive maintenance decisions.

Here’s a breakdown of its key functions and attributes:

1. Sensor Interface and Signal Conditioning:

- High-Density Inputs: Provides physical connections for 16 dynamic measurement channels (e.g., for vibration, dynamic pressure) and 4 tachometer channels (for speed and phase reference).

- Universal Input Compatibility: The inputs are designed to accept signals from a wide range of industrial transducers, including:

- Dynamic: Accelerometers (IEPE/ICP® compatible), proximity probes (for relative vibration, displacement, axial position), velocity transducers, and dynamic pressure sensors.

- Tachometer: Proximity probes, magnetic pick-ups, and TTL signals. Tachometer channels 1 & 2 often support voltage and current inputs, while 3 & 4 might be voltage-only.

- Analog Signal Conditioning: Performs critical initial analog signal conditioning, including filtering and amplification, to prepare the raw signals for accurate analog-to-digital conversion by the companion XMx16 module.

- Transducer Power Supplies: Built-in power supplies deliver excitation voltage to various sensor types directly from the module, simplifying wiring and reducing external power supply needs.

2. Robust Physical Design and Protection:

- Card Pair Functionality: The XIO16T always operates as a “card pair” with an XMV16 (for vibration) or XMC16 (for combustion) processing module. The XIO16T is mounted in the rear card cage of the VM600 rack, directly behind its corresponding XMx16 module which sits in the front card cage.

- Secure Connections: Utilizes robust screw terminal connectors for reliable and secure connection of field wiring from sensors.

- EMI and Surge Protection: Designed with robust protection features against electromagnetic interference (EMI) and transient voltage surges, ensuring signal integrity and system resilience in harsh industrial environments. Meets relevant EMC standards.

3. Data Routing and System Integration:

- Buffered Raw Outputs: A key feature for advanced diagnostics is the provision of buffered raw sensor signals via BNC connectors. This allows maintenance personnel to connect portable data collectors or oscilloscopes directly to the live sensor signals without disrupting the operational monitoring system.

- Internal Bus Integration: The XIO16T enables internal signal sharing within the VM600 rack. Input signals can be routed via the VM600’s “Raw Bus” and “Tacho Bus” to other modules (e.g., MPC4 protection cards), reducing redundant external wiring.

- Communication Pathway: While the XIO16T handles the physical I/O, it forms the critical link for raw data transfer to the associated XMV16/XMC16 processing module, which then performs sophisticated digital signal processing (DSP), FFT analysis, and sends processed data to the rack’s CPUM (Central Processing Unit Module) and ultimately to the VibroSight® software.

Differences between 620-002-000-113 and 620-003-111-112: Specific, publicly available documentation detailing the exact differences between these two part numbers is often limited. Typically, variations in the last digits of Vibro-Meter part numbers (like -113 vs. -112) signify:

- Minor internal hardware revisions (e.g., component changes for obsolescence management, board layout optimizations).

- Pre-installed firmware versions that might offer subtle performance enhancements or bug fixes.

- Specific internal options or factory configurations that are not outwardly visible but warrant a unique part number. For most common applications, both modules will perform the core function of an XIO16T, providing the necessary I/O for 16 dynamic and 4 tachometer channels. If precise compatibility or feature verification is required, consulting official Meggitt/Parker documentation or their technical support is recommended.

Technical Specifications (Typical for VM600 XIO16T, including 620-002-000-113 & 620-003-111-112 variants):

The specifications are generally consistent across the XIO16T family, serving as the standard interface for the XMx16 processing cards.

Applications and Industries:

The VIBRO-METER VM600 XIO16T is deployed in all applications where the VM600 system is used for sophisticated condition monitoring and diagnostic analysis of critical rotating machinery. Its role as a reliable sensor interface is foundational for successful predictive maintenance programs.

Consider a large, continuous process plant, such as a chemical facility. Unscheduled downtime of critical pumps, reactors, or compressors can lead to significant production losses and safety hazards. The XIO16T, paired with XMV16 or XMC16 modules, would be used to monitor comprehensive machinery health parameters. For instance, on a multi-stage compressor, numerous vibration probes would connect to XIO16T modules. The XIO16T accurately feeds these signals to the XMV16, allowing for detailed vibration analysis (e.g., spectral analysis, orbit plots). This enables the identification of issues like bearing degradation, shaft cracks, or misalignment long before they become critical, allowing for planned, proactive maintenance.

Key applications and industries that utilize the XIO16T include:

- Power Generation:

- Gas, Steam, and Hydro Turbines, Generators: Providing the I/O interface for monitoring vibration, rotor dynamics, and combustion health to ensure efficient and safe power production.

- Balance-of-Plant (BOP) Equipment: Monitoring large pumps, fans, and motors for early fault detection.

- Oil & Gas:

- Refineries, Pipelines, Offshore Platforms, LNG Plants: Crucial for interfacing sensors on critical turbomachinery such as compressors, pumps, and gas turbines for advanced condition monitoring and diagnostic purposes, often adhering to API 670 standards.

- Chemical and Petrochemical Industries:

- Monitoring complex rotating machinery in hazardous environments where early fault detection is vital for safety, environmental protection, and process optimization.

- Heavy Manufacturing (e.g., Steel, Cement, Pulp & Paper):

- Interfacing sensors for monitoring large motors, gearboxes, and production machinery where predictive maintenance can significantly reduce operational costs and maximize uptime.

- Marine Applications:

- Monitoring propulsion systems, auxiliary engines, and other critical machinery on large commercial and naval vessels to ensure operational reliability and reduce maintenance overheads.

In essence, the XIO16T facilitates the high-fidelity acquisition of data from machinery, which is then used by the VM600 system to enable advanced diagnostics and informed decision-making for asset management.

Related Products:

The VIBRO-METER VM600 XIO16T modules (620-002-000-113 & 620-003-111-112) are integral parts of a complete VM600 system and require several other components to function as a full condition monitoring solution.

- Companion Processing Modules (Card Pair):

- VM600 XMV16 (Extended Vibration Monitoring Card): The XIO16T typically pairs with the XMV16 to form a powerful vibration condition monitoring solution. The XMV16 performs the high-resolution analog-to-digital conversion and all advanced DSP functions (FFT, orbit analysis, etc.).

- VM600 XMC16 (Extended Combustion Monitoring Card): The XIO16T also pairs with the XMC16 for combustion monitoring applications, providing the I/O for dynamic pressure signals.

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the 19-inch, 6U (or 1U for ABE056) rack housings where the XIO16T is physically installed (in the rear card cage).

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power (+5 VDC, ±12 VDC) to the VM600 rack’s backplane and all installed modules, including the XIO16T. Redundant RPS6U units are highly recommended for critical applications.

- Rack Controller and Communication Modules:

- VM600 CPUR2 / CPUM / CPUMMk2: These modules manage the overall VM600 rack, handle the configuration of the XMx16/XIO16T card pairs via software, and provide communication interfaces (e.g., Ethernet, serial) to external systems.

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller, providing physical communication ports.

- Sensors:

- Various types of industrial sensors connect to the XIO16T, including accelerometers, proximity probes, velocity transducers, dynamic pressure sensors, and tachometer sensors.

- Monitoring Software:

- VibroSight®: The comprehensive PC-based software suite used for configuring the entire VM600 system (including the XMx16/XIO16T card pairs), visualizing real-time and historical data (trends, waveforms, spectra), performing advanced diagnostic analysis, and managing alarms.

The XIO16T, by efficiently gathering and conditioning sensor data, enables its companion processing modules to provide the in-depth insights required for effective condition monitoring and predictive maintenance.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922