الوصف

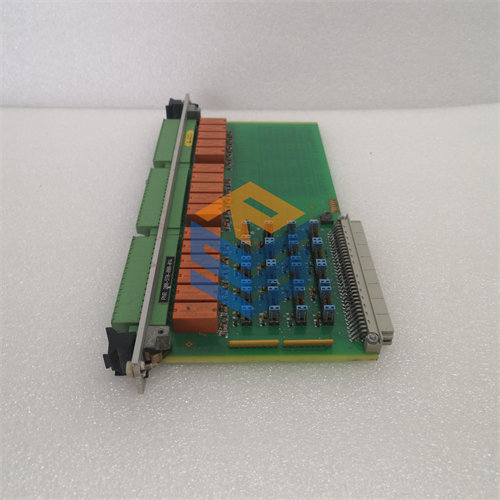

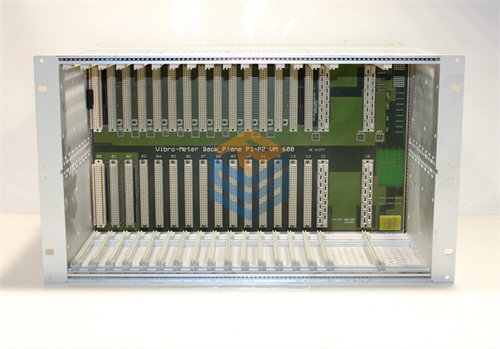

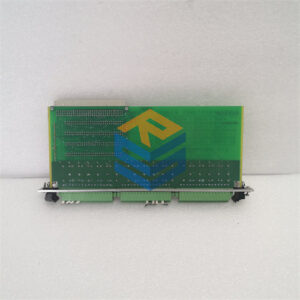

The VIBRO-METER MPC4, with part number 200-510-111-035, is a highly advanced machinery protection card. This module is the central processing unit of the VM600 series machinery protection system, which was originally developed by Vibro-Meter, a company that is now part of Meggitt Sensing Systems and operates under the Baker Hughes Bently Nevada umbrella. The MPC4’s primary role is to provide continuous, real-time monitoring and protection for critical rotating machinery.

Key Features and Functionality

The MPC4 is designed to be a versatile and robust component that can handle a variety of protection and monitoring tasks from a single module.

- Multi-Channel Inputs: This card is capable of measuring and monitoring four dynamic signal inputs and two tachometer (speed) inputs simultaneously. These inputs are highly programmable, allowing them to accept signals from a wide range of sensors.

- Sensor Versatility: The dynamic inputs can connect to sensors that measure acceleration, velocity, displacement (proximity probes), and dynamic pressure. The tachometer inputs can accept signals from proximity probes, magnetic pick-ups, or TTL sensors.

- Advanced Digital Signal Processing (DSP): The MPC4 uses advanced DSP techniques for real-time measurement. It can perform digital filtering, integration, differentiation, and rectification to calculate various physical parameters such as absolute vibration, relative shaft vibration, eccentricity, and thrust position.

- Comprehensive Protection: A key benefit of the MPC4 is its robust protection scheme. It allows for the programming of Alert, Danger, and OK set points. These alarm levels can be static or adaptive, meaning they can change based on the machine’s speed or other external information, providing a more intelligent and tailored protection strategy.

- Diagnostic Capabilities: The module includes a built-in “OK System” that continuously monitors the health of the entire measurement chain (sensors and transmission lines). This helps to quickly detect and diagnose issues like a broken wire or a faulty sensor, ensuring the system remains reliable.

Technical Specifications

Applications

The MPC4‘s robust design and extensive feature set make it an ideal choice for monitoring and protecting critical machinery across various heavy industries.

- Power Generation: Protecting gas, steam, and hydro turbines as well as generators from potentially catastrophic failures caused by high vibration or rotor instability.

- Oil & Gas: Monitoring high-speed compressors, pumps, and other essential rotating equipment on offshore platforms, in refineries, and on pipelines.

- Industrial Automation: Used in sectors like pulp and paper, mining, and manufacturing to ensure the health and safety of critical motors, fans, and other vital machinery.

Status and Replacement

The original VIBRO-METER MPC4 is considered a legacy component. While it is a highly reliable and widely installed product, it has been superseded by a newer generation. The modern successor to this product is the MPC4 Mk2, which offers enhanced performance, updated features, and compliance with the latest industry standards. Spares for the original MPC4 are still available for maintenance and repair of existing systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922