الوصف

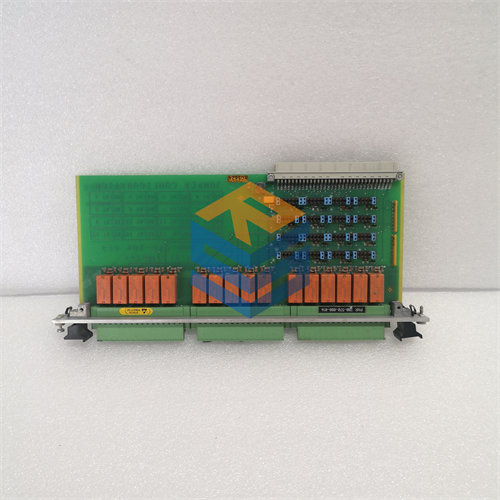

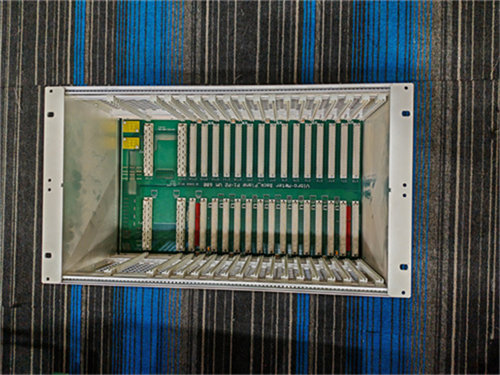

The item VIBRO-METER VM600 204-040-100-012 refers to a specific type of system rack (also known as a chassis or housing) within the Vibro-Meter VM600 series of machinery protection and condition monitoring systems.

It is a variant of the well-known VM600 ABE040 system rack.

SEO Optimized Headings:

- VIBRO-METER VM600 204-040-100-012: 6U 19-inch System Rack for Industrial Control.

- VM600 204-040-100-012: Robust Housing for Machinery Protection Modules.

- VIBRO-METER ABE040 Variant: Industrial Rack for Vibration Monitoring Systems.

- VM600 System Chassis: Supporting Critical Asset Monitoring and Diagnostics.

- 204-040-100-012 Rack: VMEbus Backplane for VM600 Modules.

- VIBRO-METER VM600 Series: Reliable Enclosures for Harsh Industrial Environments.

Product Overview:

The VIBRO-METER VM600 204-040-100-012 is a 19-inch system rack with a standard height of 6U (Rack Units). It is specifically designed to house the various electronic modules (cards) that make up a complete Vibro-Meter VM600 or VM600Mk2 machinery protection and/or condition monitoring system.

This particular part number, 204-040-100-012, is a version of the ABE040 rack, which is a common and robust housing for VM600 system components. The distinguishing feature of the “-012” variant is that it includes separate circuits in accordance with IEC/CEI 60255-5 standard, which implies enhanced insulation or electrical separation for specific applications.

Product Details:

The VIBRO-METER VM600 204-040-100-012 serves as the backbone for a VM600 monitoring system. In industrial environments, where precision and reliability are paramount, machinery protection systems must be housed in robust enclosures that facilitate proper power distribution and inter-module communication. This rack fulfills precisely that role.

Imagine a critical rotating asset like a gas turbine in a power plant. The sensors on this turbine generate continuous data (vibration, temperature, speed). This data needs to be processed, analyzed, and used to trigger alarms or even emergency shutdowns if dangerous conditions arise. All the electronic “brains” (modules) that perform these functions are housed within a VM600 system rack like the 204-040-100-012.

Here’s a breakdown of its key features and functionalities:

1. Robust Physical Construction: * Standard Form Factor: It’s a standard 19-inch rack, 6U high. This allows for easy installation into industrial cabinets or panels that conform to standard rack mounting dimensions. * Durable Material: Constructed from extruded aluminum frame and solid aluminum structural parts, ensuring it can withstand harsh industrial conditions, including vibrations, dust, and temperature variations. * Modular Design: Its design allows for the flexible insertion and removal of various VM600 modules from the front, and corresponding I/O (Input/Output) modules from the rear.

2. Integrated Electrical Infrastructure: * VMEbus Backplane: The rack features an integrated VMEbus backplane. This is critical as it provides the electrical interconnections for: * Power Distribution: Delivering regulated DC power from the power supply units (RPS6U) to all installed modules. * Signal Routing: Facilitating communication between different types of modules, including raw signal data, Tacho bus (for speed/phase reference), and Open Collector (OC) bus (for system-wide control signals). * Data Exchange: Enabling communication between processing cards (like MPC4Mk2, XMV16), the rack controller (CPUR2/CPUM), and relay cards (RLC16). * Power Supply Integration: It is designed to accommodate one or two RPS6U power supply units (AC and/or DC input versions), which are installed in the front of the rack. The ability to install two RPS6U units allows for power supply redundancy, ensuring continuous operation even if one power supply fails – a critical feature for high-availability systems. * Power Supply Check Relay: The rack includes a power supply check relay, which provides an indication (typically at the rear panel) that the installed power supplies are operating normally.

3. Capacity and Compatibility: * Slot Capacity: Provides mounting space for up to 15 single-width VM600 series cards, or a combination of single-width and multiple-width cards (e.g., an XMV16 module paired with an XIO16T I/O module might occupy two slots in total). * Compatibility: Fully compatible with all VM600 and VM600Mk2 series modules, including: * Machinery Protection Modules (MPM) like MPC4Mk2 * Condition Monitoring Modules (CMM) like XMV16, XMC16 * Analog Monitoring Modules (AMM) like AMC8 * Relay Cards (RLC16) * Rack Controller and Communication Modules (CPUR2, CPUM, IOCN)

4. Specifics of 204-040-100-012 (vs. Standard ABE040): * While very similar to the standard ABE040 rack, the “204-040-100-012” designation signifies a variant that incorporates “Separate circuits in accordance with IEC/CEI 60255-5 standard.” This standard relates to insulation coordination and electrical protection of measuring relays and protection equipment. This specific version likely offers enhanced electrical isolation, which can be crucial for applications requiring higher safety integrity levels or operation in environments with specific electrical interference or safety requirements. The standard ABE040 (e.g., 204-040-100-011) typically has similar features but might not explicitly meet this particular electrical separation standard.

In essence, the VIBRO-METER VM600 204-040-100-012 is more than just an enclosure; it is an engineered foundation that provides the structural integrity, electrical connectivity, and power distribution necessary for the reliable and continuous operation of advanced machinery protection and condition monitoring systems in demanding industrial environments.

Technical Specifications (Typical for VM600 204-040-100-012 / ABE040):

Applications and Industries:

The VIBRO-METER VM600 204-040-100-012 system rack is fundamental to any installation of the VM600 series, which is primarily used for the protection and condition monitoring of critical rotating machinery. Its enhanced electrical isolation (IEC/CEI 60255-5 compliance) can make it particularly suitable for applications with stringent safety or electromagnetic compatibility (EMC) requirements.

Consider an offshore oil and gas platform. The machinery (turbines, compressors, pumps) operates continuously in a harsh, isolated environment. Any failure can have severe financial and safety consequences. The VM600 system, housed within this robust rack, monitors these machines 24/7. The rack’s ability to provide a stable, interconnected, and potentially highly isolated environment for the monitoring modules is critical to ensuring the continuous and reliable performance of the protection system, even in challenging conditions or in proximity to other electrical systems that might generate interference.

Key applications and industries where this rack is deployed include:

- Power Generation:

- Nuclear, Thermal, Hydroelectric Power Plants: Housing systems that monitor large steam/gas turbines, generators, reactor coolant pumps, fans, and exciters. The separate circuits feature is valuable in these environments.

- Renewable Energy: Wind turbine monitoring (though often distributed systems are used for wind, centralized racks may be found in associated substations).

- Oil & Gas:

- Refineries, Pipelines, Offshore Platforms, LNG Plants: Monitoring critical turbomachinery (compressors, pumps, gas turbines) where safety and continuous operation are paramount. Compliance with standards like API 670 is often a requirement for the overall system.

- Chemical & Petrochemical Industry:

- Monitoring complex rotating equipment in plants processing hazardous materials, where robust and reliable monitoring is crucial for preventing accidents and ensuring safety.

- Heavy Manufacturing:

- Steel mills, paper mills, cement plants: Monitoring large motors, gearboxes, and fans in demanding production environments.

- Marine Industry:

- Large commercial vessels and naval ships: Monitoring propulsion systems, auxiliary engines, and other critical rotating equipment.

- Test and Development Facilities:

- Used in R&D settings for rigorous testing and long-term monitoring of new machinery designs or prototypes.

In essence, the VM600 204-040-100-012 rack provides the resilient and electrically protected foundation upon which critical machinery protection and condition monitoring systems are built, enabling reliable operation and effective asset management in the most demanding industrial settings.

Related Products:

The VIBRO-METER VM600 204-040-100-012 rack is the core housing that requires other modules to form a complete functional system. Here are the key related products it commonly interacts with:

- Rack Power Supply Units (PSU):

- VM600 RPS6U: These power supplies are installed in the front slots of the rack to provide regulated DC power (+5 VDC, ±12 VDC) to all other modules. Two RPS6U units can be installed for power redundancy.

- Machinery Protection Modules (MPM):

- VM600 MPC4Mk2: These are the primary protection cards, processing vibration, position, and speed signals to generate alarms and initiate shutdowns.

- Condition Monitoring Modules (CMM):

- VM600 XMV16: For extended vibration monitoring and advanced analysis (e.g., FFT).

- VM600 XMC16: For specialized combustion monitoring.

- Analog Monitoring Modules (AMM):

- VM600 AMC8: For monitoring analog process parameters like temperature, pressure, or flow.

- Input/Output (I/O) Cards:

- VM600 IOC4Mk2 (for MPC4Mk2): Provides physical connections for sensors and relay outputs for protection.

- VM600 XIO16T (for XMV16/XMC16): Provides physical connections for 16 dynamic and 4 tachometer sensors.

- VM600 IOC8T (for AMC8): Provides physical connections for 8 analog inputs.

- Relay Cards:

- VM600 RLC16 / RLC16Mk2: Provides additional configurable relay outputs for alarms and control actions.

- Rack Controller and Communication Modules:

- VM600 CPUR2 / CPUM / CPUMMk2: These modules manage the rack, communicate with other modules, and provide interfaces to external systems (DCS, PLC, or a PC running monitoring software).

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller, handling communication interfaces.

- Sensors:

- Various types of sensors are connected to the I/O cards within the rack, including proximity probes, accelerometers, velocity transducers, tachometer sensors, thermocouples, and RTDs.

- Monitoring Software:

- VibroSight®: The PC-based software used for configuration, data visualization, trend analysis, and alarm management of the entire VM600 system.

- Blank Panels:

- For covering any unused slots in the rack to ensure proper airflow and maintain EMC integrity.

The 204-040-100-012 rack provides the organized and protected environment for all these modules to work together seamlessly, forming a comprehensive solution for monitoring and protecting critical industrial assets.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922