الوصف

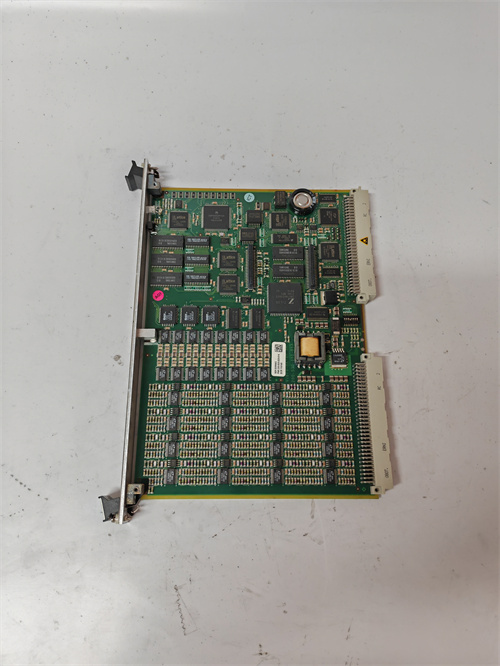

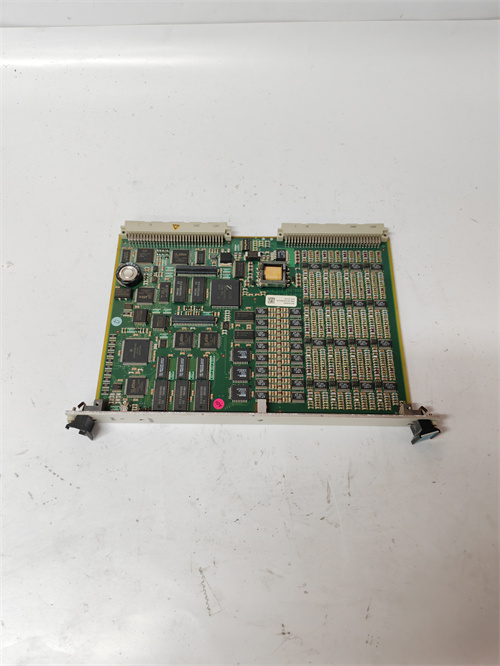

The VIBRO-METER VM600 CMC16 (Condition Monitoring Card 16) is a sophisticated and high-performance module designed for advanced machinery condition monitoring and diagnostic analysis within the modular VM600 rack-based system. It plays a critical role in proactive maintenance strategies by providing detailed, high-resolution data on the health of rotating and reciprocating machinery.

VIBRO-METER VM600 CMC16: Advanced Condition Monitoring for Critical Machinery

The VM600 CMC16 is not a machinery protection card that triggers immediate shutdowns, but rather a dedicated module for in-depth data acquisition and analysis. It complements protection systems by offering the granular data needed to predict potential failures, optimize maintenance schedules, and improve overall asset reliability.

Primary Function and Role:

The core function of the CMC16 is to acquire and process signals from a wide range of machinery sensors to provide comprehensive condition monitoring data. It’s designed to deliver highly accurate and detailed information, enabling engineers and operators to perform advanced diagnostics and identify developing faults before they escalate into critical issues.

Key Features and Capabilities:

-

16 Individually Configurable Channels: The CMC16 offers high-density monitoring with 16 channels that can be flexibly configured for various input types.

- Dynamic Inputs: Primarily used for vibration (acceleration, velocity, displacement from proximity probes) and dynamic pressure.

- Tachometer Inputs: Typically, the first 4 channels can be configured as tachometer (speed/phase reference) inputs for precise speed measurement and synchronous data acquisition.

- Static/Process Inputs: The remaining channels can be configured for static measurements like temperature (thermocouples, RTDs), current (e.g., 4-20mA), and voltage.

-

High-Resolution Data Acquisition and Processing:

- Advanced DSP Technology: Utilizes powerful Digital Signal Processors (DSP) for real-time measurement and analysis.

- High-Resolution ADCs: Employs 16 parallel programmable anti-aliasing filters and high-resolution Analog-to-Digital Converters (ADCs) for precise signal capture.

- On-board FFT Processing: Capable of performing Fast Fourier Transform (FFT) analysis (e.g., 3200-line or up to 6400-line FFTs) for detailed spectral analysis, crucial for identifying specific fault frequencies (e.g., bearing defects, gear mesh problems).

- Digital Filtering: Includes programmable digital broadband and tracking filters for signal conditioning and noise reduction.

- Synchronous and Asynchronous Sampling: Supports both time-based (asynchronous) and speed-based (synchronous/order tracking) data acquisition, essential for analyzing machinery behavior across varying operating speeds and identifying order-related phenomena.

-

Intelligent Data Logging and Alarming:

- Configurable Processed Outputs: Generates multiple configurable processed outputs per channel (e.g., up to 20), which can be frequency bands, overall values, or time-domain based parameters.

- Flexible Alarm Limits: Offers multiple configurable alarm limits (e.g., 6) per processed output, often with adaptive monitoring capabilities that adjust alarm set points based on machine operating conditions (like speed or load).

- Event-based Data Logging: Supports intelligent data logging mechanisms, including schedule-based, “on-alarm” based, and “on-exception” based logging. This ensures that high-resolution raw data (waveforms, spectra, orbits) is captured automatically when specific events or alarm conditions occur, providing crucial data for post-event analysis.

- On-board Buffer Storage: Equipped with internal memory to buffer captured data.

System Integration:

The VM600 CMC16 operates within the standard VM600 rack (chassis), such as the ABE040, ABE042, or ABE056. It forms a “card pair” with a dedicated Input/Output Card (IOC).

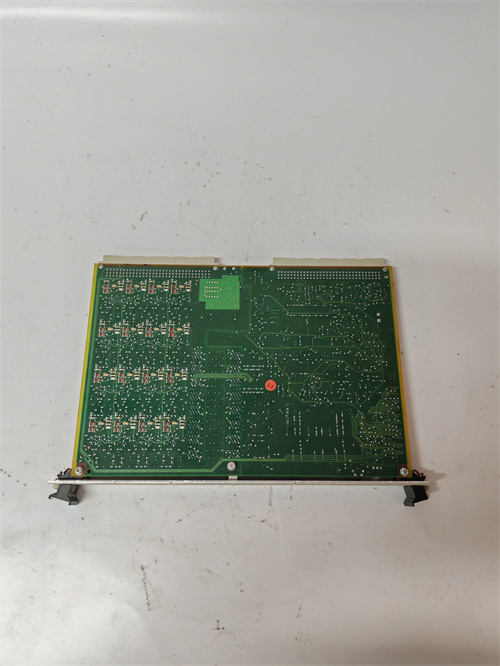

- CMC16 (Front Card): Installed in the front card cage of the VM600 rack. This is the processing module.

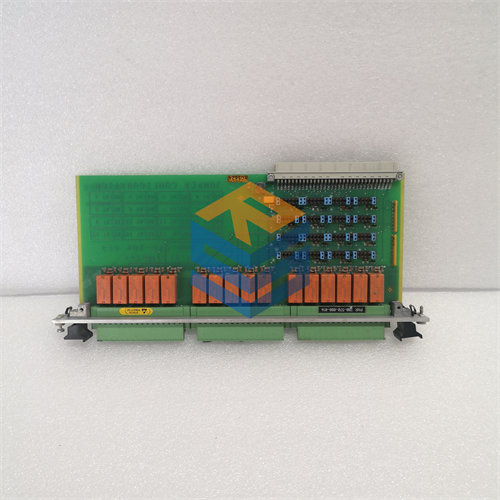

- IOC16T / XIO16T (Rear Card): The CMC16 requires a companion IOC16T or XIO16T module, which installs directly behind it in the rear card cage. This I/O card provides the physical termination points for sensor wiring, supplies transducer power, and offers buffered raw signal outputs for external diagnostic equipment.

- VM600 CPUM (Central Processing Unit Module): The CMC16 communicates with the rack’s CPUM, which manages the overall system, handles configuration via software, and provides communication interfaces (e.g., Ethernet) to external systems.

- VibroSight® Software: The CMC16 is designed for seamless integration with VibroSight®, Parker Meggitt’s comprehensive PC-based software suite. This software is used for configuring the CMC16, visualizing real-time and historical data (trends, waveforms, spectra, orbit plots), and performing advanced diagnostic analysis.

Typical Applications and Industries:

The VM600 CMC16 is widely deployed in heavy industries to monitor critical rotating and reciprocating machinery, enabling a proactive approach to maintenance and ensuring the safety and efficiency of high-value assets.

- Power Generation: Turbines (gas, steam, hydro), generators, large pumps, and fans for monitoring rotor dynamics, vibration, bearing condition, and other critical parameters.

- Oil & Gas: Turbomachinery (compressors, pumps, gas turbines) in refineries, pipelines, offshore platforms, and LNG plants, often for compliance with standards like API 670.

- Chemical and Petrochemical: Monitoring reactors, agitators, mixers, and other crucial rotating equipment where continuous operation and early fault detection are vital.

- Heavy Manufacturing: Large motors, gearboxes, crushers, and mills in steel, cement, mining, and pulp & paper industries.

- Marine Industry: Propulsion systems and auxiliary machinery on large commercial and naval vessels.

Product Status:

The VIBRO-METER VM600 system, including the CMC16, is considered a mature product line. Meggitt (now Parker Meggitt) has committed to supporting the VM600 system for existing installations, providing spare parts, repairs, and customer support.

For new installations and modernization projects, Parker Meggitt has introduced the VM600Mk2 series (e.g., XMx16 + XIO16T). While these newer modules offer enhanced functionality and performance, the original VM600 CMC16 continues to be supported for the significant installed base globally, ensuring long-term operational continuity for existing users.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922