الوصف

The user is asking about two specific part numbers for the VIBRO-METER VM600 CMC16 module: 200-530-025-014 and 200-530-111-013.

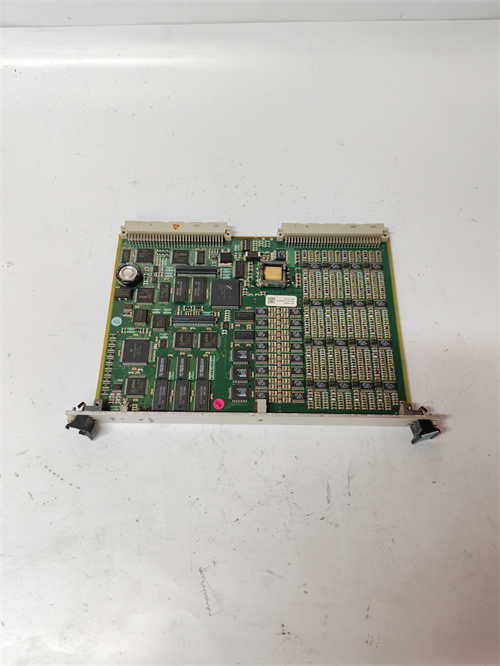

The VIBRO-METER VM600 CMC16 (Condition Monitoring Card 16) is a high-performance, intelligent processing module designed for comprehensive data acquisition and analysis within the VM600 rack-based machinery monitoring system. Unlike protection cards (like MPC4) that primarily trigger alarms and shutdowns, the CMC16 focuses on providing detailed, high-resolution data for advanced condition monitoring and diagnostic analysis. It is a key component for implementing predictive maintenance strategies.

SEO Optimized Headings:

- VIBRO-METER VM600 CMC16: Advanced 16-Channel Condition Monitoring Card.

- VM600 CMC16 (200-530-025-014 & 200-530-111-013): High-Resolution Data Acquisition for Predictive Maintenance.

- VIBRO-METER Condition Monitoring Module: Multi-Channel Dynamic and Static Inputs.

- CMC16 Card: On-board FFT Processing for Machinery Diagnostic Analysis.

- VIBRO-METER VM600 Series: Empowering Proactive Asset Management.

Product Overview:

The VIBRO-METER VM600 CMC16 is the central element in Vibro-Meter’s VM600 series Condition Monitoring System (CMS). It’s a highly capable module that integrates advanced digital signal processing (DSP) to acquire, process, and store data from various machinery sensors.

Key features common to the CMC16 include:

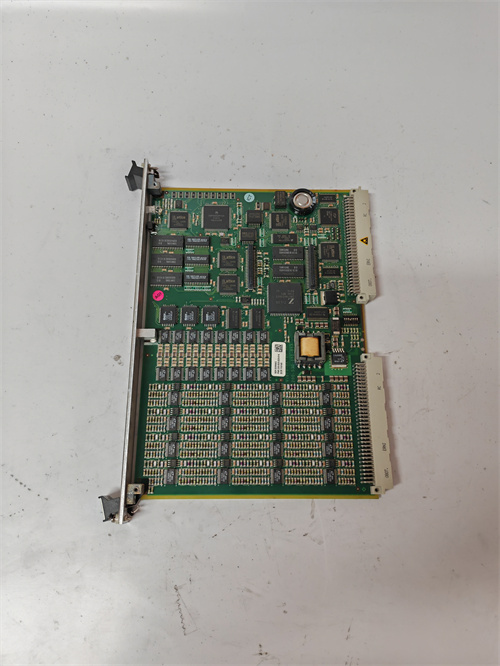

- 16 individually configurable channels: These channels can typically be configured for a mix of dynamic (vibration, pressure) and static (temperature, process) inputs. The first 4 channels are often configurable as tachometer (speed/phase reference) inputs, and the last 12 as process value inputs.

- High-resolution data acquisition: Utilizes 16 parallel programmable anti-aliasing filters and ADCs for precise measurements.

- On-board high-resolution FFT processing: Capable of performing Fast Fourier Transform (FFT) analysis (e.g., 3200-line or up to 6400-line FFTs) for detailed spectral analysis of vibration and other dynamic signals.

- Configurable processed outputs: Up to 10 or 20 fully configurable processed outputs per channel (which can be frequency bands or time-domain based outputs).

- Multiple configurable alarms: 6 configurable alarm limits per processed output, with hysteresis deadbands. Adaptive monitoring techniques can also be employed to dynamically adjust alarm set points based on machine parameters like speed and load.

- Intelligent data logging: Supports schedule-based, “on-alarm” based, and “on-exception” based data logging to capture critical data efficiently.

- On-board buffer storage: For temporary storage of captured data.

- Compatibility with VibroSight® software: For comprehensive configuration, data visualization, and advanced diagnostic analysis.

Regarding the specific part numbers (200-530-025-014 and 200-530-111-013): These different part numbers typically indicate minor hardware revisions, firmware versions, or specific factory configurations. While official datasheets explicitly detailing the differences between these exact sub-variants are not widely public, it’s common for such numerical variations to reflect:

- Minor component updates for obsolescence management.

- Improvements in manufacturing processes.

- Specific internal feature sets or enabled capabilities that are not universally present across all CMC16 variants.

- Updates to embedded firmware that might enhance performance, add minor features, or address specific issues.

Both part numbers fall under the VM600 CMC16 umbrella and share the core functionalities of a 16-channel condition monitoring card. For precise differences, consulting the manufacturer (Parker Meggitt) or their authorized distributors with the full part numbers would be necessary.

Product Details:

The VIBRO-METER VM600 CMC16 (200-530-025-014 / 200-530-111-013) is specifically designed to collect and process the in-depth data required for comprehensive condition monitoring programs. Unlike basic protection systems that merely alarm or shut down machinery, the CMC16 allows for detailed analysis to predict failures and enable proactive maintenance.

Imagine a large industrial fan in a power plant. Continuous monitoring of its bearings, gearbox, and motor is vital to prevent unscheduled outages. The CMC16 modules would continuously acquire vibration, temperature, and speed data. Through its on-board DSP, the CMC16 can perform real-time FFTs on vibration signals, allowing operators and engineers to detect subtle changes in frequency patterns that might indicate early bearing wear, unbalance, or misalignment. The module’s intelligent logging ensures that high-resolution waveforms and spectra are captured when specific conditions or alarms occur, providing crucial data for diagnosing the root cause of issues. This capability enables maintenance teams to schedule interventions during planned downtime, avoiding costly emergency repairs and maximizing equipment lifespan.

Here’s a breakdown of its key functionalities and attributes:

1. Comprehensive Data Acquisition and Processing:

- 16 Channels: High-density monitoring capability within a single module.

- Input Flexibility: Channels are highly configurable to accept a wide range of inputs:

- Dynamic: Vibration (acceleration, velocity, displacement from proximity probes), dynamic pressure.

- Static/Process: Temperature (from thermocouples, RTDs), current (e.g., 4-20mA), voltage inputs (e.g., 0-10V).

- Tachometer/Phase: The first 4 channels can often be configured for speed measurement and phase reference, critical for synchronous data acquisition and order tracking.

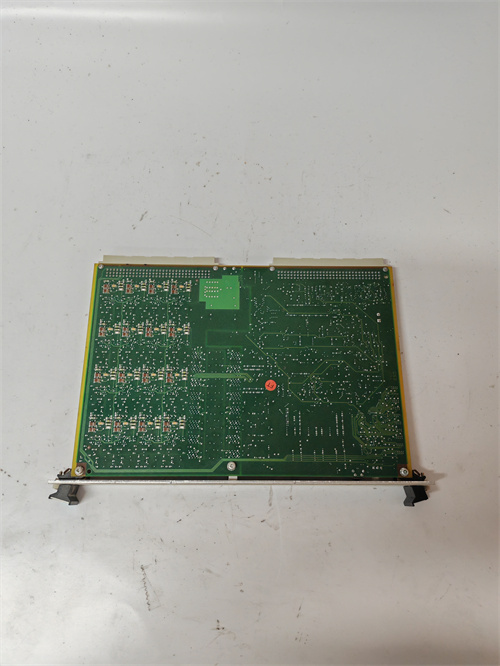

- Real-time DSP: Utilizes powerful Digital Signal Processors for real-time measurement and analysis, ensuring immediate access to critical data.

- High-Resolution FFT: Offers high-resolution Fast Fourier Transform capabilities (e.g., 3200 to 6400 lines), essential for detailed spectral analysis to identify specific fault frequencies.

- Digital Filtering: Includes programmable digital broadband and tracking filters for enhanced signal quality and analysis focus.

- Synchronous and Asynchronous Sampling: Supports both time-based (asynchronous) and speed-based (synchronous/order tracking) data acquisition, crucial for analyzing machinery behavior across varying operating speeds.

- Auto Run-up & Coast-down Detection: Automatically detects machine speed changes during start-up and shutdown, enabling the capture of critical transient data.

2. Intelligent Data Management and Alarming:

- Event-based Logging: Features intelligent data acquisition and logging, including “on alarm” or “on exception”-based logging. This ensures that high-resolution data (waveforms, spectra, orbits) is captured automatically when anomalous events occur.

- On-board Buffer Storage: Equipped with internal memory to store captured data, providing a buffer even if continuous network communication is temporarily interrupted.

- Configurable Alarms: Multiple configurable alarm levels per processed output (e.g., 6 alarms per output), often with adaptive levels that can adjust based on machine operating parameters like speed and load.

3. System Integration and Outputs:

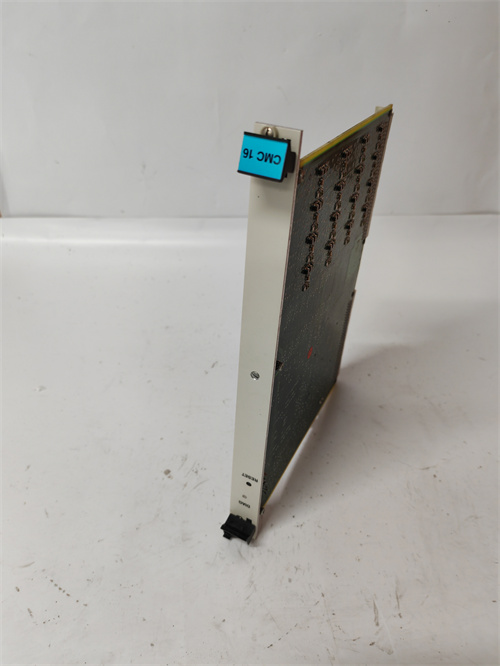

- VME Architecture: Integrates seamlessly into the VM600 rack via the VME backplane, which handles internal communication and power distribution.

- Companion I/O Module: The CMC16 (like the XMV16/XMC16) typically requires a companion IOC16T (Input/Output Card 16) or similar XIO16T variant to provide the physical sensor connections and buffered raw signal outputs. The CMC16 is installed in the front of a VM600 rack, and the IOC16T in the rear, forming a “card pair.”

- Ethernet Communication: Utilizes Ethernet for efficient data transfer to host PCs running VibroSight® software, which provides comprehensive data visualization, analysis, and diagnostic tools.

- Integration with CPUM: Communicates with the VM600 rack’s CPUM (Central Processing Unit Module) for overall system management, configuration, and higher-level communication to DCS/SCADA systems.

Technical Specifications (Typical for VM600 CMC16):

The following specifications are generally applicable to the CMC16 family. Specific values might vary slightly between particular part numbers and generations (e.g., original CMC16 vs. VM600Mk2 variants like XMx16). The provided part numbers (200-530-025-014 and 200-530-111-013) denote specific configurations within this range.

Applications and Industries:

The VIBRO-METER VM600 CMC16 is a cornerstone for advanced condition monitoring and diagnostic analysis of critical rotating and reciprocating machinery across a wide array of heavy industries. Its capability to handle a high density of channels and perform sophisticated on-board processing makes it invaluable for detailed machinery health assessment.

Consider a large, complex power generation facility. The CMC16 modules would be deployed to monitor every critical aspect of a steam turbine, from the high-speed rotor dynamics to bearing temperatures, shaft positions, and even pressure pulsations. By continuously acquiring and analyzing high-resolution vibration waveforms, frequency spectra, and trend data, the CMC16 allows engineers to detect subtle changes indicative of developing faults—such as blade resonance, rotor imbalance, shaft cracks, or even bearing degradation. This early detection capability allows for planned maintenance interventions during scheduled outages, significantly reducing the risk of catastrophic failures, minimizing unscheduled downtime, and optimizing operational efficiency.

Key applications and industries that extensively utilize the CMC16 include:

- Power Generation:

- Turbines (Gas, Steam, Hydro), Generators: Essential for monitoring rotor dynamics, vibration, thermal expansion, bearing condition, and other critical parameters to ensure safe, efficient, and continuous power production.

- Balance-of-Plant Equipment: Monitoring large pumps, fans, compressors, and motors.

- Oil & Gas:

- Refineries, Pipelines, Offshore Platforms, LNG Plants: Crucial for detailed condition monitoring of turbomachinery (compressors, pumps, gas turbines) in upstream, midstream, and downstream operations. This is vital for compliance with standards like API 670.

- Chemical and Petrochemical Industries:

- Monitoring reactors, agitators, mixers, and other critical rotating equipment where precise control and early fault detection are paramount for safety, environmental protection, and production efficiency.

- Heavy Manufacturing (e.g., Steel, Cement, Mining, Pulp & Paper):

- Monitoring large motors, gearboxes, crushers, mills, and other heavy industrial machinery where wear and tear are significant, and continuous operation is vital for production targets.

- Marine Industry:

- Monitoring propulsion systems, auxiliary engines, and other critical rotating machinery on large commercial and naval vessels to ensure operational reliability, reduce maintenance costs, and enhance safety at sea.

In essence, the VM600 CMC16 facilitates a proactive, data-driven approach to machinery maintenance, enabling organizations to predict and prevent failures, thereby enhancing asset availability, extending equipment lifespan, and ensuring overall operational safety.

Related Products:

The VIBRO-METER VM600 CMC16 modules (including 200-530-025-014 and 200-530-111-013) are integral parts of a complete VM600 system and function in conjunction with several other components to form a comprehensive monitoring solution.

- Companion I/O Module:

- VM600 IOC16T / XIO16T: The CMC16 (like the XMV16 and XMC16) requires a dedicated Input/Output Card (IOC16T or XIO16T). This module installs in the rear of the VM600 rack, directly behind the CMC16, forming a “card pair.” The IOC16T/XIO16T handles the physical wiring connections from sensors, provides transducer power, and offers buffered raw outputs for external analysis.

- VM600 System Racks (Chassis):

- ABE040, ABE042, ABE056: These are the standard 19-inch, 6U (or 1U for ABE056) rack housings that physically accommodate the CMC16 module (installed in the front card cage).

- Rack Power Supply Units (PSU):

- VM600 RPS6U: Provides the necessary regulated DC power (+5 VDC, ±12 VDC) to the VM600 rack’s backplane and all installed modules, including the CMC16. Redundant RPS6U units are commonly used for high-availability systems.

- Rack Controller and Communication Modules:

- VM600 CPUM / CPUR2 / CPUMMk2: These modules manage the overall VM600 rack, handle the configuration of the CMC16 via software, and provide communication interfaces (e.g., Ethernet, serial) to external systems like host PCs running VibroSight®, Distributed Control Systems (DCS), or Programmable Logic Controllers (PLC).

- VM600 IOCN / IOCNMk2: Companion I/O modules for the rack controller, providing physical communication ports.

- Sensors:

- A wide array of industrial sensors connect to the IOC16T/XIO16T (which interfaces with the CMC16), including accelerometers, proximity probes, velocity transducers, dynamic pressure sensors, thermocouples, RTDs, and various current/voltage transducers.

- Monitoring Software:

- VibroSight®: This is the indispensable PC-based software suite used for comprehensive configuration of the entire VM600 system, visualizing real-time and historical data (trends, waveforms, spectra, orbit plots), performing advanced diagnostic analysis, and managing alarms.

The CMC16, when integrated seamlessly with these other VM600 components, forms a powerful and scalable solution for advanced machinery condition monitoring, providing sophisticated diagnostic capabilities for optimizing asset performance and reliability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922